Black Oxide Coating Service: Enhancing Corrosion Resistance

Introduction

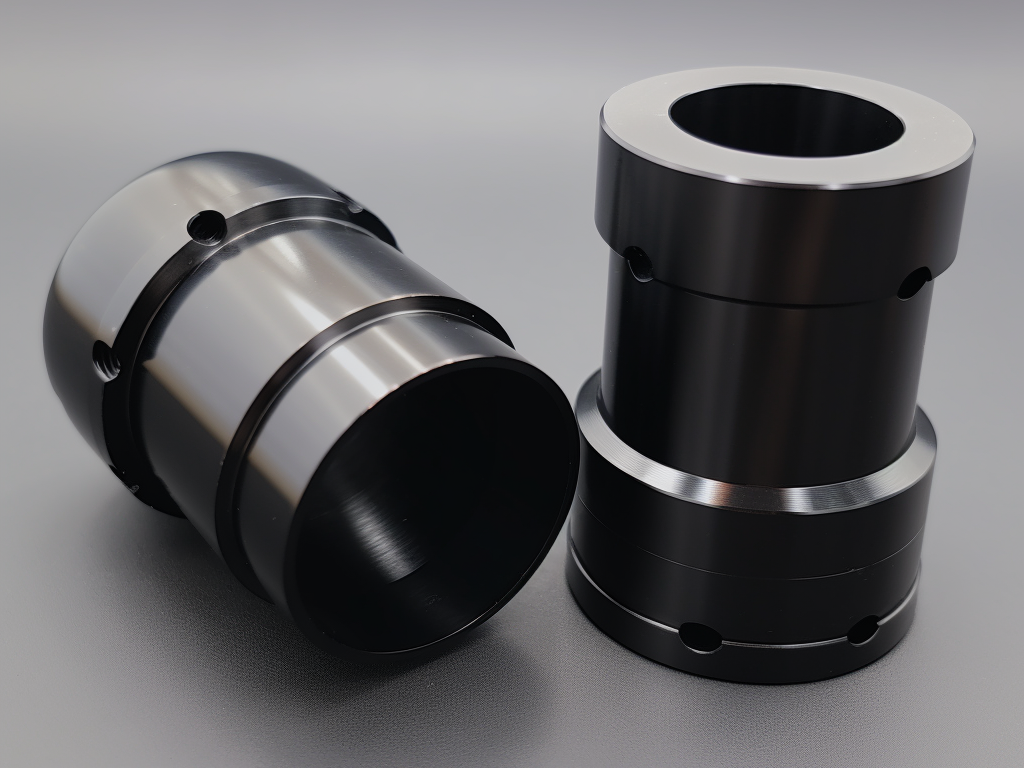

Black oxide coating is a chemical surface conversion process widely applied to ferrous metals and stainless steels to improve corrosion resistance, enhance aesthetic appearance, and minimize surface reflection. The process creates a thin, uniform black magnetite (Fe₃O₄) layer, effectively reducing corrosion, providing moderate abrasion resistance, and offering a professional finish without dimensional changes.

The global market for black oxide coatings has steadily expanded, driven by industrial requirements for cost-effective corrosion protection and visually appealing surfaces. Industries such as automotive, military, precision machinery, and tooling utilize black oxide extensively, recognizing its benefits in both functional performance and aesthetic appeal.

Black Oxide Coating Process Overview

Key Steps in Pretreatment

Surface degreasing and thorough cleaning

Mechanical or chemical descaling to remove rust and contaminants

Water rinsing to ensure a clean substrate before coating

Comparison of Core Technologies (using tables)

Technology | Process Method | Typical Thickness | Typical Applications | Efficiency |

|---|---|---|---|---|

Hot Black Oxide | Hot alkaline immersion | 0.5–2 µm uniform layer | Tooling, automotive parts, military hardware | High |

Mid-Temperature Black Oxide | Lower-temperature immersion | 0.3–1 µm consistent layer | Precision components, electronics hardware | Moderate-High |

Cold Black Oxide (Room Temp.) | Chemical immersion at room temperature | 0.1–0.5 µm thin coating | Decorative items, small fittings | Moderate |

Post-processing and Optimization

Thorough rinsing to remove residual chemicals

Application of supplementary sealants or oils for enhanced corrosion resistance

Drying and inspection for coating uniformity and quality assurance

Black Oxide Coating: Advantages and Limitations

Brief Introduction: Black oxide coating significantly enhances corrosion resistance and aesthetic quality with minimal dimensional impact. However, its performance largely depends on supplemental sealing, requiring proper post-treatment for optimal corrosion protection.

Property | Advantage / Limitation | Remarks and Typical Values |

|---|---|---|

Corrosion Resistance | Enhanced, dependent on sealing | Salt Spray Resistance (ASTM B117): Typically 100–400 hrs with oil sealant |

Surface Thickness | Negligible dimensional change | Coating thickness: ~0.5–2 µm, ideal for precision components |

Aesthetic Appeal | Professional matte black finish | Non-reflective black surface, uniform appearance |

Wear Resistance | Moderate improvement | Surface hardness increased marginally, abrasion resistance improved |

Chemical Stability | Stable under typical conditions | Chemical and solvent resistance moderate to high |

Maintenance | Requires periodic re-oiling | Easy maintenance, reapplication of sealants may be necessary |

Industrial Applications of Black Oxide Coating

Examples include:

Automotive Industry Automotive components such as gears, shafts, and fasteners benefit from black oxide coatings, significantly reducing corrosion risk and enhancing aesthetics (corrosion resistance improved by up to 50%).

Military and Defense Black oxide coatings in military hardware offer essential corrosion protection and reduce surface glare on weapon components and tactical gear (glare reduced by over 90%).

Precision Machinery Precision parts in machinery industries utilize black oxide coating to maintain precise dimensional tolerances while protecting surfaces against corrosion and wear.

Tooling and Hardware Industry Tools and hardware components benefit from enhanced appearance and moderate corrosion resistance, extending their operational lifespan significantly (service life extended by approximately 30%).

Black Oxide Coating Process Selection Guide

Material Adaptability Matrix

Substrate Type | Manufacturing Process | Recommended Black Oxide Process | Performance Gain Focus |

|---|---|---|---|

Hot Black Oxide | High corrosion protection, dimensional stability | ||

Hot or Mid-Temperature Black Oxide | Enhanced wear resistance, corrosion protection | ||

Mid-Temperature Black Oxide | Uniform aesthetic finish, improved corrosion resistance | ||

Hot Black Oxide | Improved surface durability and corrosion resistance |

Key Criteria for Evaluating Black Oxide Coating Suppliers

Equipment Capability: Confirm the supplier's capabilities for consistent temperature and chemical bath control to achieve uniform coatings.

Process Certification: Verify compliance with industry-specific quality standards (e.g., MIL-DTL-13924, ASTM D769, ISO 11408).

Test Reports: Require salt spray test results (ASTM B117), thickness measurements, and adherence to aesthetic quality standards.

Surface Treatment Technology Classification Matrix

Technology | Main Function (Specific & Comprehensive) | Key Features | Advantages |

|---|---|---|---|

Corrosion protection, aesthetic improvement, reduced surface glare | Thickness: 0.5–2 µm, Salt Spray (with sealant): >200 hrs | Minimal dimensional change, professional matte finish | |

Surface preparation, roughening | Roughness Ra: 1.0–5.0 µm, ASTM D4417 | Excellent adhesion, efficient surface cleaning | |

Surface smoothing, corrosion resistance | Surface roughness Ra <0.2 µm achievable | Superior corrosion resistance, smooth finishes | |

Aesthetic enhancement, surface imperfection masking | Roughness: Ra 0.2–2.0 µm | Attractive appearance, fingerprint resistance |

Technical Suitability Assessment (Black Oxide-Specific)

Four-Dimensional Assessment Model:

Material Compatibility: Excellent compatibility with ferrous metals, carbon steels, alloy steels, tool steels, cast iron, and stainless steel.

Performance Requirements: Provides effective corrosion resistance with proper sealing (Salt Spray ASTM B117: 100–400 hrs), uniform appearance, and minimal dimensional impact.

Process Economics: Cost-effective for high-volume production; relatively low operational cost compared to plating and coating alternatives.

Environmental and Safety Impact: Environmentally manageable with controlled chemical handling, wastewater treatment, and adherence to EPA and OSHA regulations.

FAQ (Frequently Asked Questions):

What materials are suitable for black oxide coating?

Does black oxide coating affect component dimensions?

How durable is black oxide coating for outdoor applications?

What maintenance is required for black oxide-coated parts?

Which standards apply to black oxide coatings?