A Comprehensive Guide to Polishing: Process, Classification, Functions, and Defect Solutions

When you think of a polished surface, what comes to mind? Perhaps a gleaming piece of jewelry, a shiny car, or a perfectly reflective metal surface. The importance of a polished finish cannot be overstated. It not only enhances the visual appeal of an object but also serves functional purposes. This article will explore the polishing world's process, classification, functions, and joint defects. So, let's embark on this journey and discover the secrets behind achieving that flawless shine.

Understanding the Polishing Process

Before we delve into the classification and functions of polishing, let's first understand what the process entails. Polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It involves the removal of imperfections, such as scratches, oxidation, or roughness, by applying various techniques and materials. Polishing does not improve the workpiece's dimensional accuracy or geometric shape accuracy. Still, it aims to obtain a smooth surface or mirror gloss and sometimes eliminates gloss (matting).

Different Polishing Techniques

Mechanical Polishing

This technique involves the use of mechanical force to remove imperfections. It typically employs abrasive materials, such as sandpaper, polishing wheels, or diamond pads, to gradually refine the surface. Manual operations are mainly used.

Particular parts, such as the surface of a rotating body, can be polished. Using auxiliary tools such as turntables, ultra-fine grinding and polishing methods can be used for high surface quality requirements. Ultra-fine polishing uses a unique abrasive tool, which is pressed against the surface of the workpiece to be processed in a polishing liquid containing abrasives for high-speed rotation. The surface roughness of Ra0.008μm can be achieved using this technology, which is the highest among various polishing methods. Optical lens molds often use this method.

Mechanical polishing has a greater grinding intensity on the surface of the part. When mechanically polishing angular metal parts, care should be taken not to smooth, deform, or enlarge the edges and corners.

Chemical Polishing

Chemical polishing, or pickling, utilizes chemical agents to dissolve surface irregularities. This technique is commonly used for metals and involves the application of acidic or alkaline solutions to achieve a smooth finish. To carry out chemical polishing, the convex part on the part's surface must be dissolved preferentially over the concave part, so the effect of chemical polishing should be divided into two stages to understand.

The first stage is the leveling of the geometric bumps on the metal surface during chemical polishing, removing rough surface roughness, and obtaining an average finish of several microns to tens of microns; the second stage is the smoothing of the incomplete crystallization near the grain boundary, remove tiny unevenness, in the range of 0.1 ~ 0.01μm, which is equivalent to the wavelength of light. The first stage may be called micro polishing or smoothing, and the second stage is micro polishing or glossing.

The above two polishing effects are different, and the polishing of steel in nitric acid phosphoric acid type polishing solution is taken as an example to illustrate. The change of the electrode potential and dissolution rate of steel with the concentration of nitric acid during the polishing process is shown in Figure 1. That is, as the concentration of nitric acid increases, the electrode potential of the steel gradually increases, and the dissolution rate decreases accordingly. The dissolution of low-potential areas causes steel smoothing, while the dissolution of high-potential areas forms luster. The rise of the steel surface potential is caused by some stable oxide film solids formed on the surface. It is precisely because of the formation of this stable oxide film that the parts are glossy. A diffuse layer of metal ions or dissolved products may cause smoothing.

Chemical polishing produces a polishing effect without a power supply, and its polishing principle is similar to electrolytic polishing using electric current. The effect of chemical polishing is generally worse than that of electrolytic polishing. In chemical polishing, the uneven quality of the material it will cause local potentials to vary, resulting in local cathode and anode regions, forming a local short-circuited micro-battery, and causing local dissolution of the anode. In electrolytic polishing, due to the effect of the external potential, this local cathode area can be eliminated, and complete electrolysis is performed to improve the effect.

Electrolytic Polishing

Electrolytic polishing employs an electric current to remove surface imperfections. It is commonly used for conducting materials and involves immersing the object in an electrolyte bath, where metal ions are selectively dissolved.

Electropolishing is a method of finishing metal surfaces. It is a process in which the metal product suspended in the electrolytic tank is used as the anode, electrolyzed under specific conditions. Through the dissolution of the anode metal, the fine unevenness on the product's surface is eliminated to give it a mirror-like glossy appearance. This method is often used to improve the surface finish of aluminum and its alloys, carbon steel, stainless steel, and other non-ferrous metals to meet the needs of certain parts in the working conditions (such as the need to reduce the friction coefficient of the surface, require precise tolerance fit, etc.) and improve The decorative look of metalwork.

Electropolishing can also remove some mechanical damage on metal surfaces. Unlike mechanical polishing, there is no stress on the surface after electropolishing. However, a surface that is too rough is not suitable for direct electropolishing.

Commonly Polished Materials

Metals: Metals, such as stainless steel, brass, and aluminum, are often polished to enhance their aesthetic appeal and improve their corrosion resistance.

Gemstones: Precious and semi-precious gemstones, including diamonds, rubies, and emeralds, undergo polishing to maximize their brilliance and clarity.

Glass: Glass surfaces, such as mirrors or decorative glassware, are polished to achieve a smooth and reflective finish.

Plastics: Polishing is also used for plastic materials, such as acrylic or polycarbonate, to remove scratches and give them a transparent and glossy appearance.

Surface Finish Classification

Rough Polishing

Rough polishing involves the initial stage of surface refinement. It aims to remove major imperfections, resulting in a smoother surface but with visible fine scratches.

Semi-Polishing

Semi-polishing is an intermediate stage that further refines the surface, reducing the visibility of scratches and creating a smoother texture.

Mirror Polishing

Mirror polishing is the final stage of surface refinement. It aims to achieve a mirror-like finish, free from visible scratches or imperfections, resulting in a highly reflective surface.

Functions of Polishing

Polishing serves both aesthetic and functional purposes. Let's explore its various functions:

Aesthetic Purposes

Enhancing Visual Appeal: Polishing brings out the natural beauty of materials, enhancing their colors, textures, and overall aesthetics. It adds a touch of elegance and sophistication to objects, making them visually captivating.

Creating Reflective Surfaces: Mirror-like finishes achieved through polishing create captivating reflections, making objects appear more vibrant and luxurious.

Functional Purposes

Reducing Friction and Wear: Polishing smooths out surface irregularities, reducing friction and wear. This is particularly important for moving parts in machinery, where smooth surfaces help minimize energy loss and extend the lifespan of components.

Improving Corrosion Resistance

Polished surfaces are less susceptible to corrosion as imperfections, which often serve as initiation points for corrosion, are removed. This is crucial in industries such as automotive, where polished components are less prone to rust and deterioration.

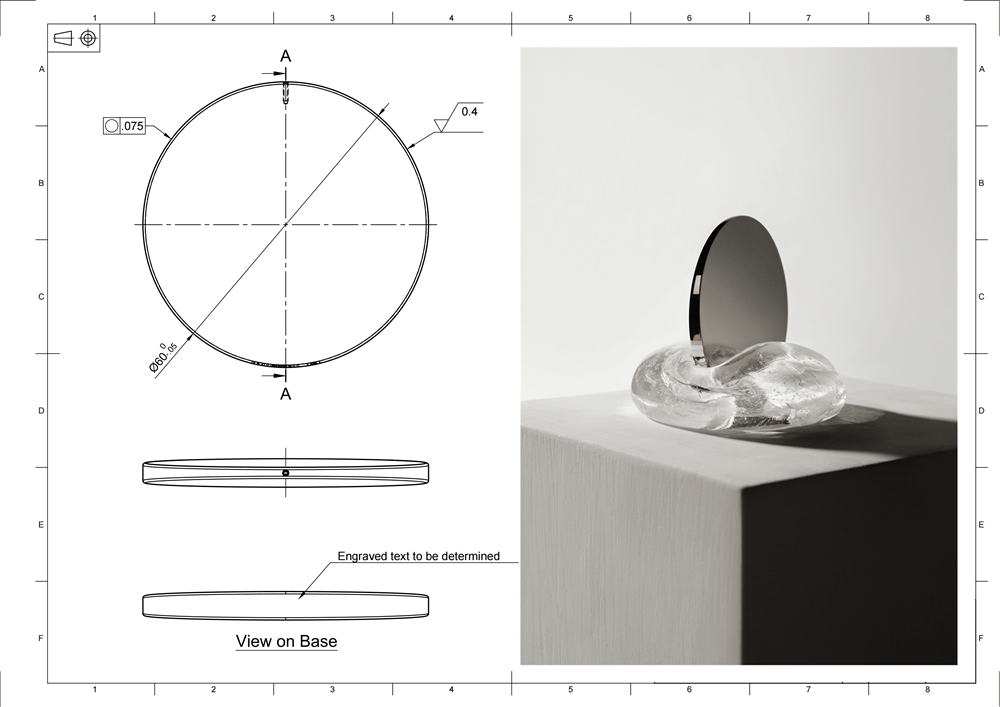

Case Study: Pocket Mirror Polishing

Let's consider a case study involving flat and curved surfaces to further illustrate the art of polishing. This is a metal double-sided mirror polishing project of a valued partner of Neway. One side is flat, and the other is concave spherical. It is required to have extremely high reflectivity, and the image will not be deformed. Works exactly like a mirror.

Stainless Steel Flat Surface Polishing

Flat surfaces require meticulous attention to detail to eliminate visible imperfections and achieve a smooth and reflective finish.

We usually use plane grinding for mirror polishing metal planes to achieve a mirror effect without scratches.

Stainless Steel Curved Surface Polishing

Curved surfaces, on the other hand, present additional challenges due to varying angles and contours. Achieving uniformity and consistency across these surfaces requires specialized techniques and expertise. Neway solves this problem by fitting and grinding the concave spherical surface with a customized spherical polishing head.

Conclusion

Polishing involves refining surfaces to achieve smoothness, luster, and functionality. Through mechanical, chemical, or electrolytic techniques, imperfections are removed, resulting in visually captivating and functionally superior objects. Polishing finds applications in various industries, from automotive to jewelry and electronics, enhancing aesthetics and performance. While defects occasionally arise, skilled artisans and advanced techniques ensure optimal results. So, next time you admire a flawless shine, remember the intricate process and skill that goes into achieving that polished perfection.