What Kind of Precision Range and Quality Consistency Can MIM Parts Create?

What Kind of Precision Range and Quality Consistency Can MIM Parts Create?

Introduction

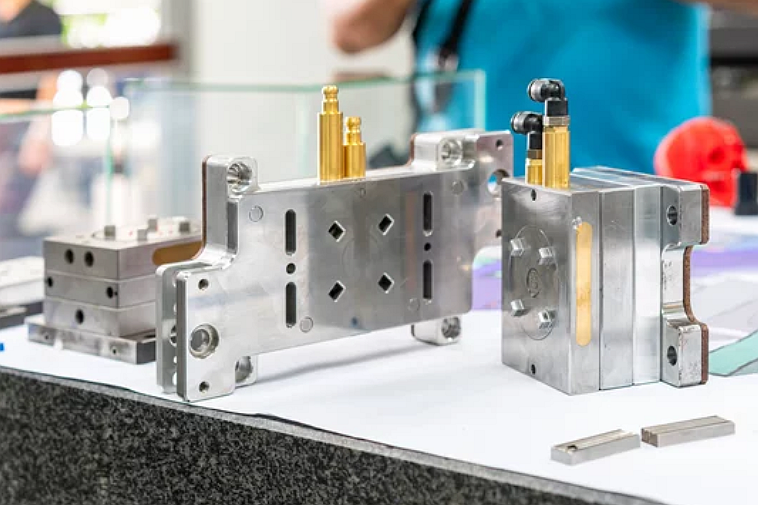

Metal Injection Molding (MIM) has emerged as a powerful technique in modern manufacturing, seamlessly combining plastic molding methods with powdered metallurgy. Precision and consistent quality are crucial in medical device manufacturing, aerospace, automotive, and electronics industries, where component reliability significantly impacts safety, functionality, and consumer satisfaction. This article explores the precision range and quality consistency achievable through MIM.

Understanding Precision in Metal Injection Molding

Precision in manufacturing refers to repeatedly producing components within defined dimensional tolerances. In MIM, precision typically involves dimensional accuracy, feature accuracy, and surface finish quality. MIM parts typically achieve dimensional tolerances ranging from ±0.1% to ±0.5% of intended dimensions. Factors influencing precision include material properties, mold accuracy, injection parameters, and sintering conditions.

Precision Range Achievable by MIM

Dimensional Precision

MIM consistently achieves high dimensional accuracy, comfortably maintaining tolerances around ±0.3% of nominal dimensions, with tighter controls available as needed. Controlled shrinkage during sintering, precise tooling, and optimized processing conditions significantly influence accuracy. Industries like medical and aerospace benefit greatly from this accuracy due to their critical functional and safety demands.

Surface Finish Precision

MIM provides superior surface finishes, frequently achieving Ra values below 0.8 micrometers. Mold quality and material selection strongly influence this outcome. Exceptional surface finishes are essential for medical implants, precision electronics, and cosmetic automotive parts.

Feature Precision

MIM excels in manufacturing highly detailed features such as micro-sized holes (0.1mm), intricate threading, and thin-walled structures (0.3 mm). Examples include precision electronics connectors, surgical instruments, and threaded components in precision engineering.

Consistency of Quality in MIM Parts

Repeatability and Process Stability

A notable strength of MIM is exceptional repeatability, consistently producing detailed components across extensive production runs. Stability depends on meticulous process management, accurate temperature control, injection pressures, and optimized sintering processes.

Quality Control Practices

MIM manufacturers employ robust quality assurance practices such as dimensional inspections, surface inspections, and advanced non-destructive testing. Statistical Process Control (SPC) helps identify and promptly correct deviations, ensuring consistent performance.

Applications Highlighting Precision and Consistency

Medical Devices

MIM frequently creates surgical tools and implants demanding stringent tolerances and impeccable consistency. Complex geometries like surgical blades, orthopedic implants, and dental components benefit greatly from MIM’s precision.

Aerospace Components

MIM produces critical aerospace components like turbine blades, valve parts, and sensor casings. Consistent quality and dimensional precision through MIM enhance safety and performance by reducing weight, ensuring structural integrity, and improving aerodynamic efficiency.

Automotive Industry

Precision and consistency are essential in automotive manufacturing. MIM reliably produces high-quality components, including fuel injector nozzles, sensor housings, and transmission parts, which are crucial for reliable vehicle performance.

Electronics

Precision and consistency in electronic components are vital for functionality. MIM produces connectors, complex casings, and miniature components with precise dimensions and consistent quality, which is integral for electronic reliability.

Comparing Precision and Consistency of MIM to Other Manufacturing Methods

CNC Machining

CNC machining offers excellent accuracy and surface finishes but is costly for intricate, high-volume parts. MIM achieves similar precision more economically at scale.

Die Casting

While die casting is efficient for mass production, it struggles with intricate features and fine surface finishes compared to MIM, making MIM superior for complex geometries.

Investment Casting

Investment casting provides excellent surface finishes and precision but lacks MIM’s reproducibility over large production runs, typically requiring additional processing.

Metal Additive Manufacturing (3D Printing)

Metal additive manufacturing excels in rapid prototyping and small batches but cannot match MIM’s large-volume consistency, repeatability, and cost-effectiveness.

Challenges in Maintaining Precision and Consistency

Maintaining precision and consistency in MIM involves managing shrinkage variations, distortion, and material inconsistencies. Precise process control, careful material selection, and advanced mold designs mitigate these challenges.

Achieving High Consistency

Inspection and Quality Assurance

Stringent inspections are essential, including dimensional inspection, surface testing, and non-destructive methods. SPC methodologies maintain tight tolerances and continuous improvement.

Future Developments and Technological Innovations

AI and Machine Learning

Integrating AI into the MIM process enables predictive modeling and adaptive control, dramatically improving precision and consistency.

Materials Science Advancements

Emerging materials tailored specifically for MIM applications enhance precision, consistency, and mechanical properties, expanding potential applications.

Sintering and Debinding Technologies

Advancements in sintering techniques, uniform heating methods, and advanced debinding processes further enhance precision and consistency.

Conclusion

MIM stands out for its exceptional ability to consistently achieve precise, detailed components. MIM meets stringent industry requirements by offering dimensional accuracy, superior surface finishes, and reliable repeatability. With ongoing innovations, MIM’s precision and consistency will continue solidifying its leading role in manufacturing complex metal components.