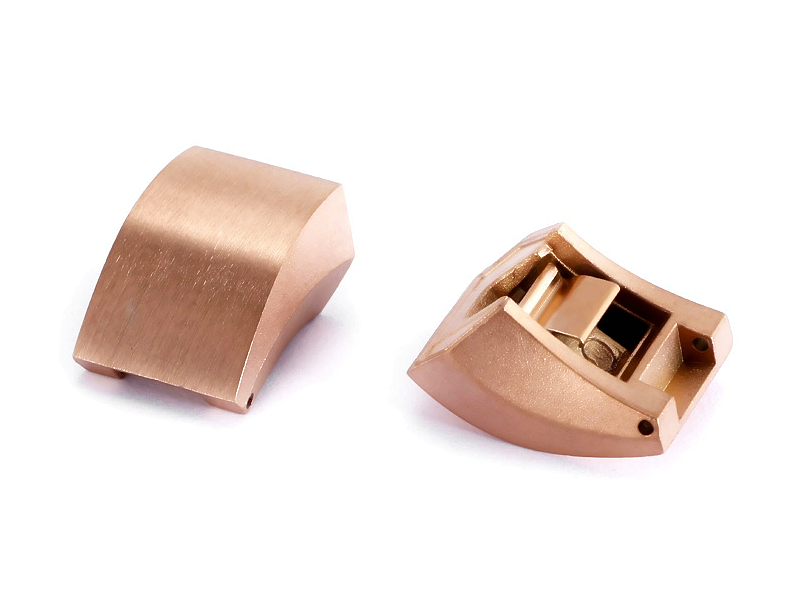

What Kind of Geometric Shapes and Complex Details Can Metal Injected Parts Achieve?

Metal Injection Molding (MIM) is a sophisticated manufacturing technique renowned for producing complex, highly detailed, and precise metal components. By combining the versatility of plastic injection molding with the strength and durability of metals, MIM enables designers and engineers to achieve intricate geometric shapes that were previously impractical or too costly with traditional metalworking techniques like die casting.

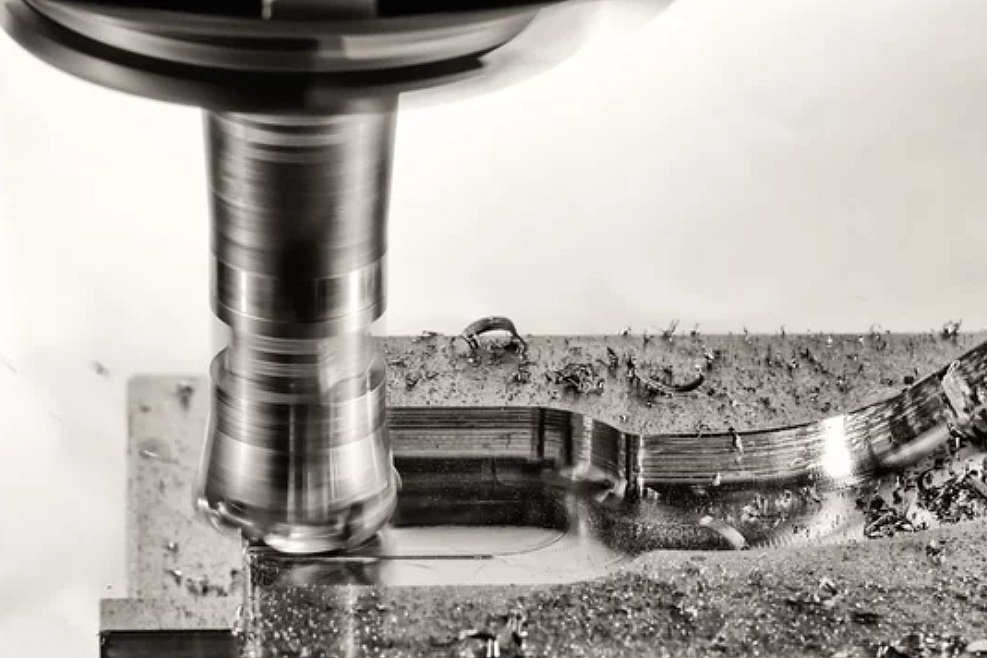

How Metal Injection Molding Works

Metal Injection Molding starts by blending fine metal powders with polymer binders, creating a moldable feedstock. This feedstock is then injected under pressure into precision molds. After the part solidifies, it undergoes debinding to remove the polymer binder, followed by high-temperature sintering, fusing metal particles into dense, solid parts.

Geometric Capabilities of MIM

Complex Internal Channels

MIM effortlessly produces intricate internal channels and cavities, crucial for fluid dynamics in medical devices, hydraulic systems, and aerospace components.

Thin-Walled Components

The MIM process achieves thin walls and intricate structures, essential for lightweight and compact parts in consumer electronics and automotive sensors.

Fine Surface Detail

Surface finishes achievable with MIM closely replicate mold textures, facilitating the production of detailed elements like logos, threads, or knurled patterns without additional machining.

Undercuts and Complex Angles

MIM readily accommodates undercuts and complicated geometries, which is beneficial for seamless designs in precision medical instruments, automotive, and aerospace components.

Advantages of MIM's Complex Geometries

Functional Integration

MIM allows designers to integrate multiple functionalities into a single component, significantly simplifying assembly, enhancing durability, and reducing costs, which is particularly beneficial in consumer electronics.

Enhanced Performance

Complex geometries produced through MIM deliver superior performance by optimizing aerodynamics, fluid management, and structural integrity, which are highly valuable for precision-engineered aerospace components.

Cost-Effective Manufacturing

Compared to traditional machining or casting processes, MIM significantly reduces costs for complex metal components, especially at high production volumes.

Industries Utilizing MIM Complexities

Medical Applications

MIM excels in manufacturing precise and complex medical components like surgical instruments, orthodontic brackets, and implants, offering advanced biocompatibility and high dimensional accuracy.

Automotive Components

MIM is extensively utilized in automotive applications for parts such as turbocharger rotors, fuel injection components, and sensor housings, requiring precise internal and external geometries.

Aerospace Applications

Components like turbine blades and sensor housings, demanding exact dimensions and exceptional reliability, benefit significantly from the precise geometric capabilities provided by MIM.

Electronics and Telecommunications

MIM-produced intricate components, such as precision hinges and connector housings, are crucial in modern compact consumer electronics, enabling functionality and aesthetic appeal.

Design Considerations

Shrinkage Management: Careful planning for shrinkage during sintering ensures dimensional accuracy.

Draft Angles: Incorporating slight draft angles improves mold release and reduces defects.

Uniform Wall Thickness: Ensures uniform sintering and prevents distortion.

Material Choices and Applications

MIM supports diverse materials, including:

Stainless steel, excellent for corrosion-resistant applications.

Titanium alloys, ideal for aerospace and medical implants.

Cobalt-chrome alloys for orthopedic implants require exceptional strength and corrosion resistance.

Future Innovations

Emerging techniques, such as combining additive manufacturing with MIM (Metal Binder Jetting), promise even greater geometric complexity. Advanced computational modeling and AI-driven simulation technologies also continue to enhance MIM precision and capabilities.

Conclusion

MIM provides unmatched advantages in manufacturing highly intricate and precise metal parts, significantly expanding the possibilities for complex geometries across numerous industries. By understanding and applying MIM best practices, designers and manufacturers can produce complex, functional, and cost-effective parts that were previously unattainable through conventional methods.