What is Metal Injection Molding? How does It work?

Metal Injection Molding (MIM) is a new type of metal injection molding near-net forming technology derived from the plastic injection molding industry. MIM combines the advantages of plastic injection molding, such as low cost and the ability to produce precision, complex shapes, with the advantages of powder metallurgy, such as high strength and good wear resistance metal forming.

What is Metal Injection Molding (MIM)?

The MIM process begins with mixing metal powder and a binder material. The mixture is then injected into a mold using a plastic injection molding machine. The molded part is then subjected to a debinding process, in which the binder is removed. Then is the sintering process, which is a process that causes the metal powder to bond together and form a solid part.

MIM is a versatile process that can produce various metal parts. MIM parts are used in various industries, including automotive, aerospace, medical, and electronics. Although MIM is suitable for small metal parts with complex structures and hard metal parts (Such as Tool steels, Tungsten Alloy, and cobalt Alloys), it has natural advantages. Still, not all metal materials are available for metal injection molding, which is also one of the limitations of the MIM process.

Metal Injection Molding Features

The MIM process is a manufacturing process that injects powdered metals into a die to create components with unique chemical compositions and mechanical and physical properties. Traditional precision casting methods cannot achieve multiple MIM advantages and properties. Metal injection molding technology can create porous, semi-dense, or fully dense materials and products, such as oil bearings, gears, cams, guide rods, knives, and more. The MIM process is a net-shape process that does not require cutting or machining.

Minimizes segregation of alloy components

Metal injection molding technology minimizes alloy components' segregation, eliminating coarse and uneven casting structures. This is important for the production of high-performance materials, such as rare earth permanent magnet materials, rare earth hydrogen storage materials, rare earth luminescent materials, rare earth catalysts, high-temperature superconducting materials, new metal materials (such as Al-Li alloys, heat-resistant Al alloys, superalloys, powder corrosion-resistant stainless steel, powder high-speed steel, and high-temperature structural materials of intermetallic compounds.

High-performance non-equilibrium materials

Metal injection molding can produce high-performance, non-equilibrium materials, such as amorphous, microcrystalline, quasicrystalline, nanocrystalline, and supersaturated solid solutions. These materials have excellent electrical, magnetic, optical, and mechanical properties.

Higher tolerance

When comparing metal injection molding vs. casting, you will find that the MIM process can reach a tighter tolerance than casting. MIM parts without post-processing can reach an accuracy of 0.02mm. This is not possible with the casting process.

Easy composite production

Metal injection molding makes it easy to produce composites, which allows for the full utilization of the characteristics of each component material. This is a low-cost production technology for high-performance metal matrix and ceramic composite materials.

High complexity

Metal injection molding can produce materials and products with unique structures (like undercuts) and properties that ordinary smelting methods cannot produce. These include new porous biological materials, porous separation membrane materials, high-performance structural ceramic abrasives, and functional ceramic materials.

Automated mass production

Metal injection molding can achieve near-net formation and automated mass production, reducing resource and energy consumption. The material utilization rate of metal and ceramic powder injection molding is about 98%

Scrap metal reuse

Metal injection molding is a new technology that can effectively regenerate and comprehensively utilize materials. It can use ore, tailings, steelmaking sludge, rolling steel scale, and recycled scrap metal as raw materials.

Hard metal alloy forming

Returning to the metal injection molding history, you will find that this process was initially used for military products, such as tungsten alloy armor-piercing warheads. Later, with the advancement of technology, it was gradually used in hard or high-temperature metals that are difficult to process. Metal injection molding technology manufactures many of our standard machining tools and hardware abrasives. This technology is becoming increasingly important as we look for ways to reduce reliance on traditional manufacturing methods and conserve resources.

How Does Metal Injection Molding Work?

Metal powder injection molding combines the advantages of the plastic injection molding process and powder metallurgy process, and has the manufacturing difficulty of both processes.

Powder Preparation

Powder preparation is the first step in metal injection molding (MIM). It is a critical step that determines the quality of the final part. The metal powder must be high quality, prepared, and controlled to produce high-quality parts. The preparation method for metal powder is usually mechanical and physical-chemical.

The first step in powder preparation is to select the appropriate metal powder. The type of metal powder will depend on the desired properties of the final part. For example, if the part is to be used in a high-temperature environment, a powder made from a high-temperature alloy will be required. Once the metal powder has been selected, it must be processed to remove contaminants. This can be done by sieving, ultrasonic cleaning, or combining methods.

The next step is to size the powder particles. The particle size will affect the powder's flowability and the part's final properties. The particle size is typically controlled by passing the powder through a series of sieves.

The final step in powder preparation is to blend the powder. This is done to ensure that the powder is uniform and that there are no clumps of powder. The powder is typically blended in a tumbling machine. Once the powder has been prepared, it can be used in the MIM process.

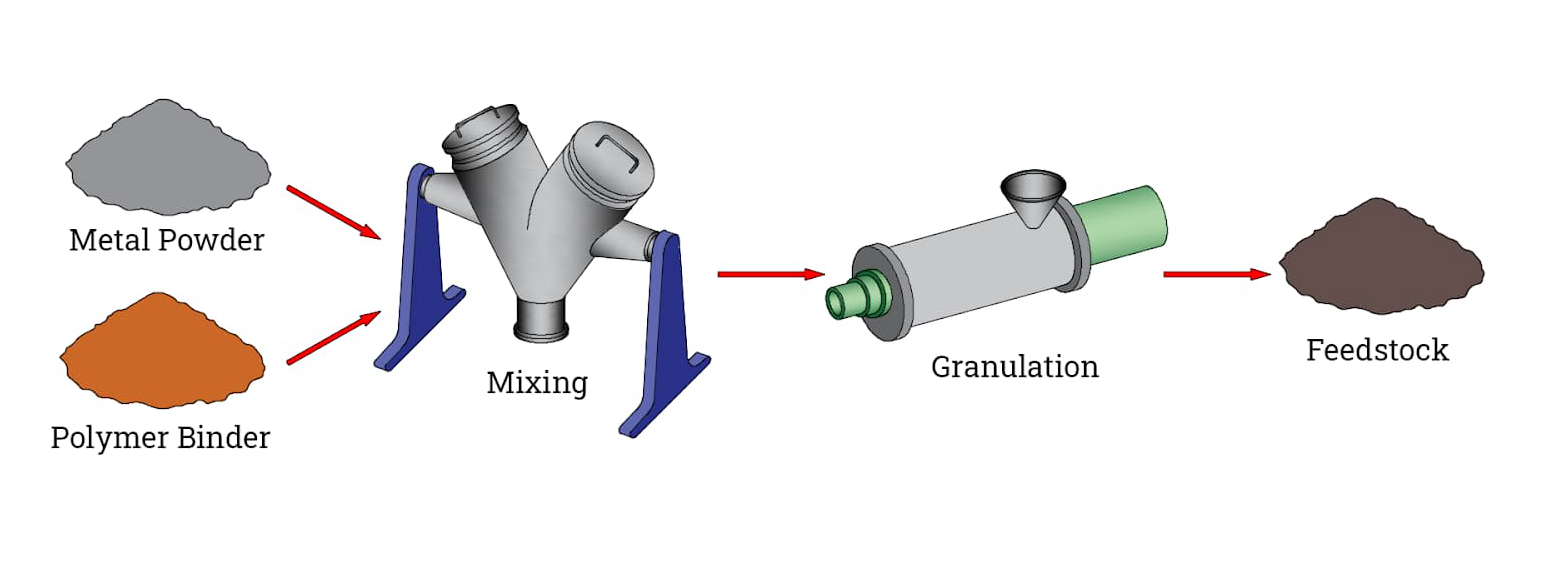

Binder Material Mixing

The metal powder is mixed with a binder material in a large mixing chamber. The binder is typically a thermoplastic material, such as polyethylene or polypropylene. It makes the powder flowable, which allows it to be injected into a mold and helps to bind the metal powder together, creating a solid and durable part. It can also be used to create parts with various properties, such as strength, lightness, and porosity. The amount of binder added to the powder depends on the desired properties of the final part. For example, a part that needs to be strong and durable will require more binder than one that needs to be lightweight and porous.

Feedstock Preparation And Injection Molding

The first step in MIM is to prepare the feedstock. This involves mixing the metal powder and binder. The metal powder is typically made of a fine, high-purity metal, such as stainless steel, titanium, or copper. The binder is typically a thermoplastic polymer, such as wax or nylon. The metal powder and binder are mixed in a machine called a mixer. The mixer ensures that the metal powder and binder are evenly distributed throughout the feedstock. Once the metal powder and binder are mixed, the feedstock is granulated. Granulating makes the feedstock easier to handle and inject into the mold. The feedstock is granulated by passing it through a series of rotating drums. The drums have blades that break the feedstock into small pieces.

MIM-Feedstock

The next step is to inject the feedstock into the mold. This is done using a plastic injection molding machine. The plastic injection molding machine is a large machine that heats the feedstock and then forces it into the mold. The mold is typically made of steel or aluminum. The mold is designed to create the desired shape of the part. The plastic injection molding machine heats the feedstock to its melting point. A piston then forces the molten feedstock into the mold. The piston forces the feedstock into all of the small details of the mold. Once the feedstock is in the mold, it cools and hardens. The part is ejected from the mold once the feedstock has cooled and hardened. The part is then ready for debinding and sintering.

Debinding

The molded part is first heated to 100-200 degrees Celsius. This temperature is low enough to prevent the metal powder from melting but high enough to start to vaporize the binder. The binder vaporizes and is carried away by a flow of inert gas. The debinding process is typically carried out in two stages. In the first stage, the majority of the binder is removed. In the second stage, the remaining binder is removed to a high degree of accuracy.

The debinding process is an essential step in metal injection molding. It is necessary to remove the binder to allow the metal powder to sinter together and form a robust and solid part. The debinding process can be carried out using various methods, but the most common methods are thermal debinding, solvent debinding, and catalytic debinding.

Thermal debinding is the most common method of debinding. It is a simple and efficient process that can be carried out in various furnaces. The temperature of the furnace is gradually increased to a point where the binder begins to vaporize. The binder vaporizes and is carried away by a flow of inert gas. The debinding process is typically carried out in two stages. In the first stage, the majority of the binder is removed. In the second stage, the remaining binder is removed to a high degree of accuracy.

Solvent debinding is a less common method of debinding. It is a more expensive process than thermal debinding, but it can be used to remove more of the binder. In solvent debinding, the molded part is immersed in a solvent that dissolves the binder. The solvent is then removed from the part, carrying the binder. Solvent debinding is a more time-consuming process than thermal debinding, but it can produce parts with a higher degree of accuracy.

Catalytic debinding is a newer method of debinding. It is a more efficient process than thermal debinding, and it can remove more of the binder. In catalytic debinding, a catalyst is added to the furnace. The catalyst reacts with the binder, causing it to decompose and vaporize. A flow of inert gas then carries the vaporized binder away. Catalytic debinding is a more expensive process than thermal debinding, but it can produce parts with a higher degree of accuracy.

Sintering

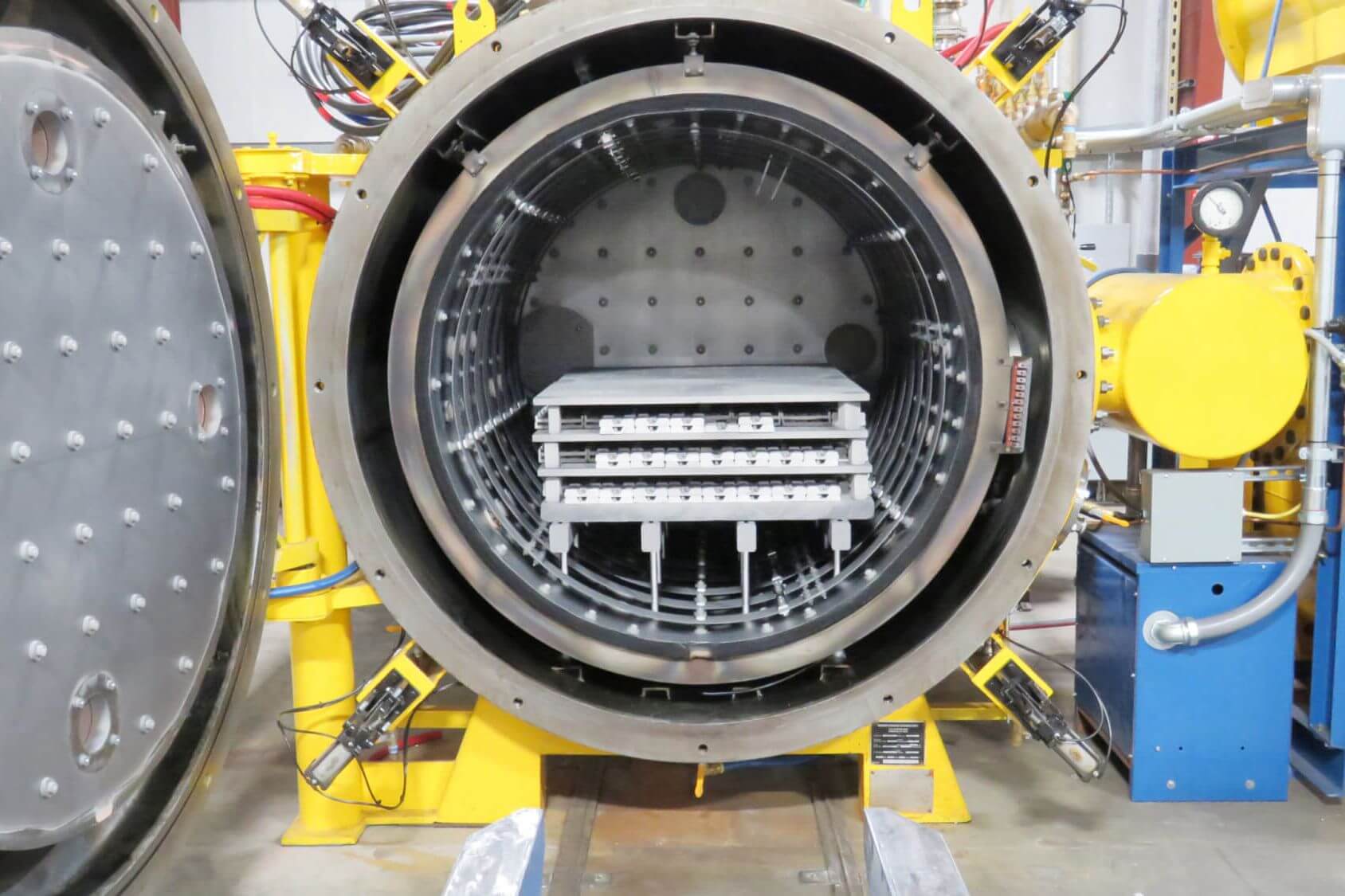

The debinded part is then sintered. Sintering is a process that causes the metal powder to bond together and form a solid part. Sintering is typically done in a furnace at 1,200-1,600 degrees Fahrenheit. Sintering is divided into pressureless sintering and hot-pressing sintering.

For example, you are making a metal injection molded part for a car. The part is made of a metal powder mixed with a binder. The part is then injected into a mold and heated. The binder melts and flows from the mold, leaving a porous metal part behind. This part is then sintered. During sintering, the metal particles heat up and bond together. This removes the pores and creates a solid metal part. The part is then cooled and removed from the mold. Sintering is an essential step in the metal injection molding process. It is what creates the solid metal part from the porous metal powder. Sintering also improves the strength, toughness, and density of the part.

Sintering is a solid-state process, meaning the metal powder does not melt during sintering. Since the pores in the part are removed during sintering, the part will be smaller than before. We call it the MIM parts shrinkage ratio. The sintering temperature is typically below the melting point of the metal powder. The sintering time depends on the size and shape of the part, the type of metal powder, and the desired properties of the part. Sintering can occur in various atmospheres, including air, vacuum, and inert gas. The atmosphere used for sintering can affect the properties of the part.

Post-processing

The sintered part may require post-processing, such as heat treatment, machining, or plating, to achieve better properties. Typically, the sintered blank shrinks and deforms slightly. We need to correct the shape through post-processing. We will achieve our desired product requirements through the following post-processing steps:

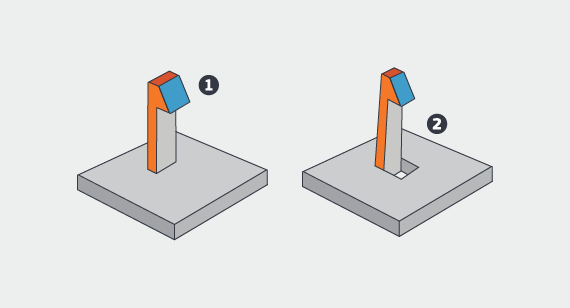

Shaping

These tiny deformations are corrected by pressing the blank into the correcting mold.

Heat treatment

Heat treatment is a process that alters the properties of a metal by heating it to a specific temperature and then cooling it at a controlled rate. This can be done to improve the part's strength, toughness, or machinability. For example, the hardness of 17-4 PH stainless steel before heat treatment is HRC 20, and it can reach HRC 40 after heat treatment.

CNC Machining

CNC Machining is a process that uses cutting tools to remove material from a part to achieve the desired shape or dimensions. This can be done to improve the fit and finish of the part or to add features that MIM cannot create.

Surface Finishing

After finishing the precision and feature machining, the surface treatment of the part is finally carried out. Usually includes plating, polishing, powder coating, etc.

For example, plating is a process that coats a metal part with a thin layer of another metal. This can be done to improve the part's appearance, protect it from corrosion, or improve its electrical conductivity. Plating is divided into PVD plating and electroplating.

Advantages of the MIM process

Complex geometries: MIM can create parts with complex geometries that would be difficult or impossible to create using other manufacturing processes. For example, MIM can create parts with interior features like gears, bearings, and connectors.

You can understand the complexity and shape that the plastic injection molding process can achieve. Metal injection molding can do it, too.

High precision

MIM parts can be produced to very tight tolerances, making them ideal for applications where precision is critical. Min tolerances down to +/-0.02 mm and min thin wall down to 0.4 mm can be achieved, which is impossible with hard metal forming processes such as lost wax casting. For example, MIM parts are often used in medical devices, aerospace applications, and the telecommunications industry.

Strong and durable

MIM parts are typically solid and durable, making them ideal for various applications. For example, MIM parts are often used in automotive and industrial applications.

Cost-effective

Metal injection molding costs mainly include mold fee, injection molding fee, degreasing fee, sintering fee, shaping fee, post-processing fee, etc. Even producing a single part has to go through all the processes. MIM can be a cost-effective manufacturing process for high-volume production runs. For example, MIM is often used to produce parts for the automotive and electronics industries. But not suited for low-volume production.

Environmentally friendly

MIM is a relatively environmentally friendly manufacturing process, producing very little waste. For example, MIM does not require solvents or hazardous chemicals.

Disadvantages of the MIM Process

High initial investment

The cost of setting up a MIM production line can be high. MIM requires specialized equipment, such as an injection molding machine, a debinding furnace, and a sintering furnace.

Longer lead times

The lead time for MIM parts can be longer than that of other manufacturing processes. This is because MIM is a multi-step process that requires time for the metal powder to be compacted, sintered, and machined.

Limited material selection

The range of materials that can be used in MIM is limited. This is because not all metals are available in powder form. Currently, Neway provides copper alloys, iron-based and tungsten alloys, and titanium alloys in metal injection molding services. However, the range of materials used in MIM is expanding as new technologies are developed.

Why Choose Neway

Metal injection molding is a production process for small metal parts with high complexity, high precision, and relatively large output. If you are looking for a MIM supplier, please get in touch with us.

For over 30 years, Neway has been a trusted manufacturer of non-standard parts, offering a wide range of services, including metal, ceramic, and plastic injection molding, precision casting, sheet metal processing, and rapid proofing. With our extensive experience and expertise, we consistently deliver exceptional results that meet the highest industry standards. Our commitment to quality, cutting-edge technology, and competitive pricing makes us the ideal choice for businesses seeking reliable, cost-effective manufacturing solutions. And as a special promotion for 2023, new customers try Neway with 20% off the first order, providing an excellent opportunity to experience our top-notch service at a reduced cost. Partner with Neway and elevate your manufacturing processes to new heights.