What is Gravity Cast | Process, Materials, Pros, Limitations

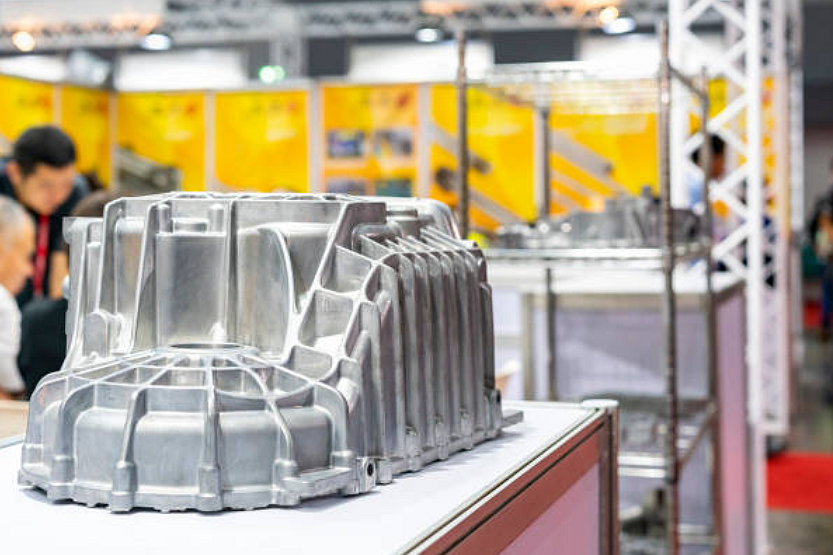

Gravity casting, also known as permanent mold casting or gravity die casting, is a manufacturing process used to produce high-quality, dimensionally accurate metal parts. The casting method relies on gravity to fill a mold with molten metal. The process involves pouring molten metal into a reusable metal mold or die, typically made of steel or iron.

Casting can be divided into sand casting and metal casting according to the material of the casting mold. The precision casting factory is familiar with these two casting processes, and designs and manufactures these two types of casting molds by itself.

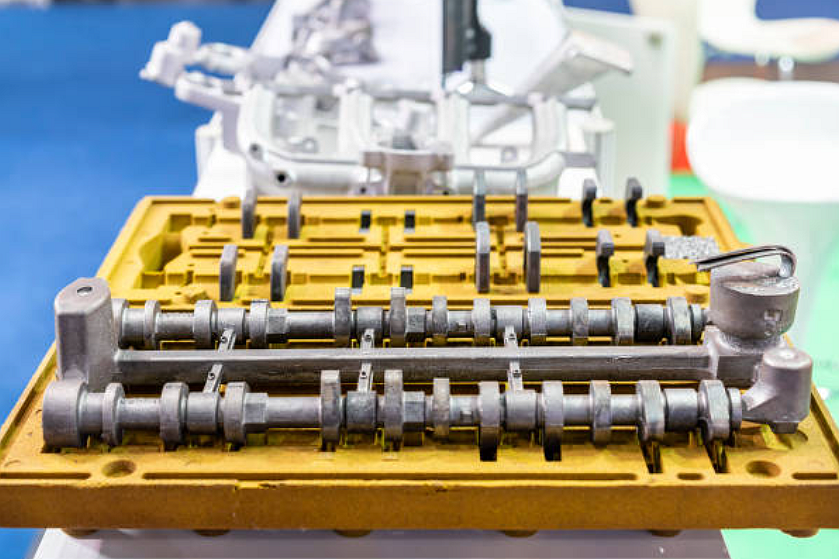

Casting can also be divided into gravity casting and pressure casting according to the pouring process of molten metal. Gravity casting refers to the process in which molten metal is injected into the mold under the action of the gravity of the earth, also known as casting. Gravity casting in a broad sense includes sand casting, metal casting, investment casting, lost foam casting, mud casting, etc.; gravity casting, in a narrow sense, refers to metal casting. Die casting refers to the process of injecting molten metal into the mold under the action of other external forces (excluding gravity). Die casting in a broad sense includes pressure casting and vacuum casting of die casting machines, low pressure casting, centrifugal casting, etc.; pressure casting in a narrow sense refers to metal die casting of die casting machines, referred to as die casting. Precision Casting Factory has long been engaged in gravity casting of sand molds and metal molds. These casting processes are the most commonly used in non-ferrous metal casting, and they are also relatively cheap.

What is Gravity Cast Process

The Gravity Cast process, also known as gravity die casting, or permanent mold casting, is a method used for the production of metal parts with intricate shapes and fine details. It is commonly used for casting aluminum and other non-ferrous metals.

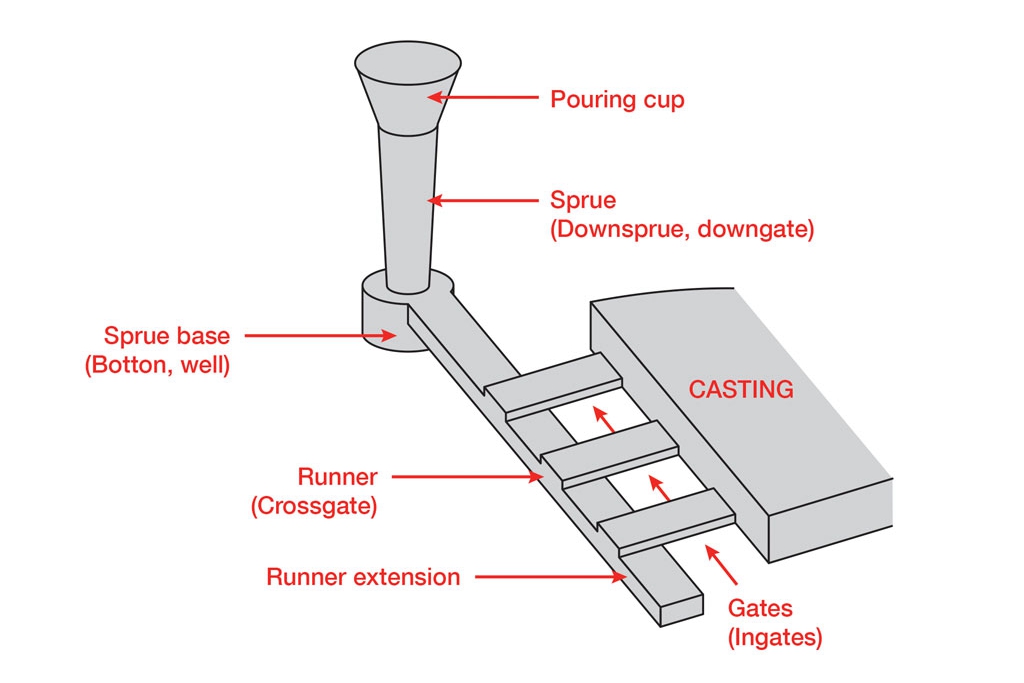

The process involves using a reusable metal mold, typically made of steel or iron, preheated to a specific temperature. The mold consists of two halves clamped together to form a cavity in the desired shape of the final part. The mold is designed with gating and riser systems to facilitate the flow of molten metal and allow for the escape of gases during solidification.

To begin the casting process, the mold is coated with a lubricant to prevent sticking and promote easy release of the part. The molten metal, typically aluminum, is poured into the mold cavity using gravity, called "gravity cast." The force of gravity ensures a consistent and controlled flow of the molten metal into the mold.

As the molten metal fills the mold, it gradually solidifies and takes the shape of the cavity. The cooling process can be accelerated by cooling channels or a water-cooled mold. Once the metal has solidified and cooled sufficiently, the mold is opened, and the solidified part, known as the casting, is removed.

Gravity casting offers several advantages. It allows for producing complex shapes and thin-walled parts with high dimensional accuracy. The process is relatively fast and efficient compared to other casting methods. Additionally, reusable metal molds have a longer lifespan, making it a cost-effective option for medium to high-volume production.

However, gravity casting does have limitations. It may not be suitable for parts with extremely intricate designs or very small features. The process also requires more labor and time compared to other casting techniques, such as die casting. Nevertheless, gravity casting remains a popular choice for various applications, including automotive, aerospace, and consumer goods industries.

Step-by-Step Process of Gravity Casting

Pattern creation:

The process begins with the creation of a pattern, which is a replica of the desired final part. The pattern is typically made from wood, plastic, or metal and is used to create the mold.

The pattern serves as a replica of the final part, providing the shape and dimensions required for the mold. Accurate pattern creation is crucial to ensure the mold accurately reflects the desired part. Precision and attention to detail are essential.

Mold preparation

Two mold halves, usually made of steel or sand, are prepared. The molds are cleaned and coated with a lubricant to prevent sticking and aid in easily removing the casting.

The mold preparation involves cleaning and applying a mold lubricant to the mold surfaces. This prevents sticking and facilitates the smooth removal of the casting. Thorough mold cleaning and proper lubricant application ensure easy mold release and minimize the risk of defects in the casting.

Mold assembly

The two mold halves are securely clamped together, creating a closed mold cavity. The mold is designed with gating and riser systems to facilitate the flow of molten metal and allow for the escape of gases during solidification.

The mold halves are securely clamped together to create a closed mold cavity. The gating and riser systems enable the controlled flow of molten metal and the escape of gases. Precise alignment and secure clamping of the mold halves are essential to prevent leakage, ensure proper metal flow, and promote consistent solidification.

Mold Preheating

The assembled mold is preheated to a specific temperature. Preheating helps in achieving better metal flow and solidification during the casting process.

Preheating the mold helps achieve better metal flow and solidification by minimizing temperature variations. Maintaining the appropriate preheating temperature and ensuring uniform mold heating enhance the casting's quality and dimensional accuracy.

Molten metal preparation

The metal, often aluminum or other non-ferrous alloys, is melted in a furnace or crucible. The metal is heated to its appropriate casting temperature, determined based on the specific material used.

The metal is melted and heated to its specific casting temperature, ensuring it is in a liquid state for pouring. Accurate temperature control and proper alloy composition are crucial to achieving the desired fluidity and preventing gravity casting defects like shrinkage or porosity.

Pouring

Once the molten metal reaches the desired temperature, it is poured into a ladle or pouring basin. From there, the metal is poured into the mold cavity using gravity. The force of gravity ensures a controlled and consistent flow of the molten metal.

Molten metal is poured into the mold cavity, filling it to create the desired shape. Controlled pouring speed, proper gating design and sufficient metal volume ensure complete cavity filling without turbulence, air entrapment, or metal splash.

Solidification

As the molten metal fills the mold cavity, it gradually solidifies and forms a pattern within the mold. The cooling process can be accelerated by cooling channels within the mold or water-cooled mold.

The molten metal cools and solidifies, taking the shape of the mold cavity and forming the casting. Adequate cooling time, proper cooling channels, and controlled solidification promote uniform metal structure, and dimensional accuracy, and minimize defects like cracks or shrinkage.

Cooling and solidification

The filled mold can cool and solidify for a sufficient time, typically until the entire casting has solidified. The cooling time depends on the gravity casting parts' size and complexity. Sufficient cooling time, optimal cooling rate, and appropriate cooling mechanisms prevent premature demolding and ensure the casting's structural integrity.

Mold opening

The mold is opened once the casting has solidified and cooled adequately. The two mold halves are separated, revealing the solidified casting inside. The mold halves are separated to release the solidified casting. Proper demolding techniques and careful handling prevent damage to the casting and the mold, ensuring the successful removal of the casting.

Casting removal

The casting is removed from the mold cavity. It may require some shaking or gentle tapping to ensure complete release from the mold. Excess material, such as gating and risers, may also need to be trimmed or machined off. Proper trimming techniques, precision machining, and attention to detail during removal prevent damage to the casting and maintain dimensional accuracy.

Finishing

The casting may undergo further finishing operations, such as grinding, sanding, machining, or surface treatments, to achieve the desired final appearance, dimensions, and surface quality.

The skillful execution of finishing operations, adherence to specifications, and quality control ensure the casting meets the required surface finish, tolerances, and overall quality standards.

Gravity Cast Materials

Gravity casting is commonly used for casting various non-ferrous metals, particularly aluminum alloys. Aluminum offers several advantages for gravity casting due to its low melting point, excellent fluidity, and good mechanical properties. However, other non-ferrous materials can also be used in the gravity casting process. Here are some common gravity cast materials

Aluminum alloys

Aluminum and its alloys are widely used in gravity casting due to their lightweight, high strength-to-weight ratio, good corrosion resistance, and excellent thermal conductivity. Different aluminum alloy compositions can be chosen based on specific application requirements.

Some commonly used aluminum alloy grades for gravity casting include:

- A356: This is a widely used aluminum-silicon-magnesium alloy known for its good strength, ductility, and excellent castability. A356 Data Sheet

- A380: This aluminum-silicon alloy offers good fluidity, high strength, and excellent resistance to corrosion and wear. A380 Data Sheet

- ADC12: It is an aluminum alloy containing silicon and other elements, offering good castability, high mechanical strength, and excellent heat resistance. ADC12 Data Sheet

Copper alloys

Copper-based alloys, such as brass and bronze, can also be gravity cast. These alloys exhibit good electrical and thermal conductivity, as well as excellent wear resistance. They are often utilized in applications that require high strength, durability, and good heat transfer properties.

Common copper alloys used in gravity casting include:

- C83600 (Red Brass): It is a lead-free copper-zinc-tin alloy known for its excellent corrosion resistance, high strength, and good machinability. C83600 Data Sheet

- C95400 (Aluminum Bronze): This copper-aluminum alloy offers high strength, excellent corrosion resistance, and good wear resistance. C95400 Data Sheet

Zinc alloys

Zinc alloys are known for their excellent casting properties, including high fluidity, low melting points, and good dimensional accuracy. They offer good corrosion resistance, high strength, and are often used in applications where intricate shapes or thin walls are required, such as decorative components or small mechanical parts.

Common zinc alloy grades used in gravity casting include:

- Zamak 3 (ASTM AG40A): It is a widely used zinc alloy known for its excellent castability, high dimensional accuracy, and good mechanical properties. Zamak 3 Data Sheet

- Zamak 5 (ASTM AC41A): This zinc alloy offers improved strength and hardness compared to Zamak 3, making it suitable for applications requiring higher mechanical performance. Zamak 5 Data Sheet

Magnesium alloys

Magnesium alloys possess low density, excellent strength-to-weight ratio, good damping capacity, and high thermal conductivity. Gravity casting with magnesium alloys is less common than with aluminum, but it can be employed in applications where lightweight components with good mechanical properties are needed, such as aerospace or automotive parts.

Some commonly used magnesium alloy grades for gravity casting include:

- AZ91D: It is a magnesium-aluminum-zinc alloy known for its lightweight properties, good strength-to-weight ratio, and excellent castability. AZ91D Data Sheet

- AM60B: This magnesium-aluminum alloy offers high strength, good corrosion resistance, and excellent dimensional stability. AM60B Data Sheet

Gravity Mold Classification

Gravity molds can be classified based on various factors, including their construction, complexity, and application. Here are some common classifications of gravity molds:

1. Single-piece or Solid Molds: These molds are made from a single block of material, such as metal or resin, and have a simple construction. They are typically used for producing simple-shaped castings with minimal complexity.

2. Split Molds: Split molds consist of two or more halves joined together to form the mold cavity. The mold halves can be separated for easy removal of the casting. Split molds allow for more complex part geometries and accommodate features that would be difficult to create with a solid mold.

3. Permanent Molds: Permanent molds, also known as permanent die molds or permanent mold casting, are made from durable materials such as metal. They are designed for multiple uses and can withstand repeated casting cycles. Permanent molds offer higher dimensional accuracy and better surface finish than expendable molds.

4. Expendable Molds: Expendable molds, also called disposable molds, are designed for single-use or a limited number of castings. They are typically made from materials like sand, plaster, or investment casting wax. Expendable molds are often used for intricate or custom-shaped castings and are more cost-effective for low to medium-production volumes.

5. Open Molds: Open molds are characterized by a flat or shallow cavity, where the molten metal is poured directly into the mold without gating systems. They are commonly used for casting flat or plate-like components.

6. Closed Molds: Closed molds have a three-dimensional cavity that encloses the entire part shape. The molten metal is poured into the gating system, which directs the flow into the mold cavity. Closed molds provide more control over metal flow, solidification, and part quality.

7. Shell Molds: Shell molds are made by coating a pattern with a ceramic or resin-based material. The coated pattern is then heated to cure the shell, creating a durable mold. Shell molds offer excellent dimensional accuracy, and a good surface finish, and can be used for ferrous and non-ferrous metals.

These are general classifications, and mold types can be variations and combinations based on specific casting requirements and processes. The choice of mold type depends on factors such as part complexity, material, desired casting quality, production volume, and cost considerations.

Considerations of Gravity Mold Design

Gravity mold design plays a crucial role in the success of the gravity casting process. A well-designed mold ensures proper metal flow, minimizes defects, and produces high-quality castings. Here are some key considerations for gravity mold design:

1. Part Design: The mold design should accommodate the desired part geometry, including its shape, size, and features. It should allow for proper metal flow and solidification without causing defects such as shrinkage or porosity. Design for manufacturability and ease of demolding should also be considered.

2. Gating System: The gating system controls the flow of molten metal into the mold cavity. It should be designed to promote smooth and controlled filling, ensuring uniform metal distribution throughout the part. Proper gate size, shape, and placement are important to minimize turbulence, air entrapment, and mold erosion.

3. Riser Design: Risers are reservoirs that supply additional molten metal during solidification to compensate for shrinkage and prevent defects. Well-designed risers should be placed strategically to ensure proper feeding of the casting and minimize porosity, shrinkage, or cold shuts.

4. Cooling System: The cooling system helps control the solidification process and achieve the desired casting properties. Cooling channels or water-cooled mold designs can be incorporated to optimize cooling rates and minimize thermal gradients, ensuring uniform solidification and dimensional stability.

5. Venting: Proper venting is essential to escape gases during metal filling and solidification. Insufficient venting can result in gas porosity or trapped air pockets. Adequate vent placement and sizing should be considered to ensure effective gas evacuation.

6. Mold Material and Coatings: The mold material should be selected based on the casting material and its thermal properties. Common choices include steel or iron. Additionally, applying appropriate mold coatings or release agents helps facilitate easy part removal, prevents sticking, and reduces mold wear.

7. Draft Angles: Draft angles are included in the mold design to enable easy part removal from the mold cavity. Adequate draft angles minimize the risk of part damage and ensure smooth demolding without distortion or surface defects.

8. Mold Maintenance: Design considerations should also include ease of mold maintenance, such as accessibility for cleaning, repairing, or replacing components. Well-maintained molds contribute to consistent casting quality and prolonged mold life.

It's important to note that mold design requirements may vary depending on the specific casting material, part complexity, and production volume. Consulting with experienced mold designers and considering industry standards and best practices can help optimize the gravity mold design for a successful casting process.

Defects of Gravity Casting

Gravity casting, like any other casting process, can be susceptible to various defects that may affect the quality and integrity of the castings. Here are some common defects encountered in gravity casting:

1. Porosity: Porosity refers to the presence of voids or air pockets in the casting. It can be caused by inadequate venting, improper gating, high pouring temperatures, or excessive turbulence during metal flow. Porosity can weaken the casting and affect its mechanical properties.

2. Shrinkage: Shrinkage defects occur due to the contraction of the molten metal during solidification. Shrinkage can result in voids, cracks, or distortion in the casting. Insufficient riser design or inadequate feeding of molten metal to compensate for volume shrinkage are common causes of shrinkage defects.

3. Cold Shuts: Cold shuts occur when two or more streams of molten metal fail to fuse properly during filling, resulting in incomplete fusion and a visible line or seam in the casting. Cold shuts can be caused by low pouring temperature, improper gating, or inadequate mold filling.

4. Misruns: Misruns happen when the molten metal does not completely fill the mold cavity, leading to incomplete castings. Insufficient metal fluidity, improper gating design, or low pouring temperature can contribute to misruns.

5. Inclusions: Inclusions are foreign materials, such as oxides, slag, or sand particles, that become trapped in the casting during the pouring process. They can result from inadequate filtration, improper gating, or contamination of the molten metal.

6. Surface Defects: Various surface defects can occur in gravity castings, including sand or mold wash, rough surfaces, or uneven texture. These defects can be caused by inadequate mold preparation, poor mold release, or improper mold coatings.

7. Dimensional Inaccuracies: Gravity castings may experience dimensional inaccuracies, such as oversize or undersize dimensions, warping, or distortion. These issues can be attributed to improper mold design, inadequate cooling, or improper solidification control.

8. Mold Degradation: Over time, molds can degrade or wear out due to repeated use, resulting in reduced casting quality. Mold degradation can lead to surface defects, dimensional inaccuracies, or decreased mold life.

9. Mold Filling Imbalance: Uneven mold cavity filling can result in casting defects, such as flow lines or incomplete sections. This imbalance can occur due to improper gating, uneven metal flow, or inadequate venting.

10. Surface Finish Issues: Gravity castings may experience poor surface finish, including roughness, pitting, or surface blemishes. Improper mold preparation, inadequate mold coatings, or contamination of the molten metal can contribute to surface finish issues.

Solutions and Precaution to Gravity Casting Defects

To address and prevent common defects in gravity casting, here are some solutions and precautions that can be taken:

1. Porosity:

- Improve mold venting to allow for proper gas escape during filling.

- Optimize gating and pouring system design to minimize turbulence.

- Use degassing techniques to remove dissolved gases from the molten metal.

- Control pouring temperature to avoid excessive gas entrapment.

2. Shrinkage:

- Optimize riser design and placement to provide adequate feeding and compensate for shrinkage.

- Control cooling rates and solidification time to minimize volume reduction.

- Modify casting design to eliminate thick sections or sharp corners that promote shrinkage.

3. Cold Shuts:

- Ensure proper gating design to facilitate proper fusion of molten metal streams.

- Optimize pouring temperature and metal flow to ensure complete fusion.

- Use suitable mold coatings or release agents to promote proper metal flow.

4. Misruns:

- Optimize gating system design to facilitate proper metal flow and cavity filling.

- Ensure adequate metal fluidity by controlling pouring temperature and alloy composition.

- Modify mold design or use suitable mold coatings to reduce resistance to metal flow.

5. Inclusions:

- Implement effective filtration systems to remove impurities from the molten metal.

- Use appropriate crucibles and ladles to minimize contaminants.

- Maintain proper metal handling and storage practices to prevent contamination.

6. Surface Defects:

- Ensure proper mold preparation, including cleaning, coating, and mold release application.

- Use suitable mold coatings or release agents to achieve a smooth surface finish.

- Address any issues with mold surface quality, such as cracks or rough spots.

7. Dimensional Inaccuracies:

- Optimize mold design to account for shrinkage and ensure proper dimensional control.

- Implement adequate cooling and solidification control to minimize distortion or warping.

- Monitor and control mold temperature to prevent dimensional variations.

8. Mold Degradation:

- Implement regular mold maintenance and repair to ensure proper mold functionality.

- Use suitable mold materials and coatings to enhance durability and resistance to wear.

- Monitor mold condition and retire molds that exhibit significant degradation.

9. Mold Filling Imbalance:

- Optimize gating design to ensure balanced metal flow and minimize flow imbalances.

- Ensure consistent and controlled pouring practices to achieve uniform mold filling.

- Implement proper venting to facilitate proper metal flow and reduce imbalances.

10. Surface Finish Issues:

- Implement proper mold preparation, including cleaning and mold coating application.

- Use suitable mold coatings or release agents to achieve the desired surface finish.

- Monitor and control process parameters, such as pouring temperature and metal flow, to avoid surface defects.

Advantages of Gravity Casting

Gravity casting has these advantages due to the specific characteristics and process dynamics involved in the gravity casting method. Here's why gravity casting offers these advantages:

1. Controlled Solidification: Gravity casting allows for a controlled and gradual solidification of the molten metal. The force of gravity aids in the smooth and uniform filling of the mold cavity, minimizing turbulence and promoting proper solidification. This controlled solidification process results in fine-grained structures, reduced porosity, and improved mechanical properties of the castings.

2. Low Pressure and Turbulence: Gravity casting operates at lower filling pressures than other casting processes like die casting. The lower pressure and minimal turbulence during metal flow help reduce the occurrence of defects, such as porosity or incomplete fills. This improves casting quality, including better surface finish and dimensional accuracy.

3. Mold Design and Surface Finish: Gravity casting utilizes permanent molds, which are typically made from durable materials like metal. These molds can be machined or polished to achieve smooth cavity surfaces, resulting in castings with excellent surface finish. The precise mold design and surface preparation contribute to the high-quality finish of gravity castings.

4. Design Complexity and Flexibility: The nature of gravity casting allows for producing complex parts with intricate geometries. The molten metal fills the mold cavity under the influence of gravity, enabling the casting of thin walls, undercuts, and intricate features. This design flexibility makes gravity casting suitable for various applications with diverse part geometries.

5. Cost-Effective Tooling: Gravity casting requires relatively simple and cost-effective tooling compared to die casting, where complex molds and high-pressure systems are involved. The permanent molds used in gravity casting can be reused for multiple casting cycles, reducing the need for frequent mold replacements and lowering overall production costs.

6. Material Versatility: Gravity casting supports a wide range of materials, including both ferrous and non-ferrous alloys. This material versatility allows for producing castings with various properties and performance characteristics to meet specific application requirements. Materials like aluminum, copper, and magnesium are commonly cast using the gravity casting method.

7. Process Stability and Control: Gravity casting offers good process stability and control. The pouring temperature, filling time, and cooling rates can be carefully monitored and controlled to optimize casting quality and minimize defects. The slower solidification rate and reduced part distortion contribute to the dimensional stability of gravity castings.

Overall, the combination of controlled solidification, low pressure and turbulence, precise mold design, material versatility, and process control contribute to the advantages offered by gravity casting. These factors result in high-quality castings with excellent surface finish, dimensional accuracy, and desirable mechanical properties while maintaining cost-effectiveness and design flexibility.