What Are The Prototyping Methods Of Custom Metal Parts?

Overview of Custom Metal Parts Prototyping

Custom metal parts prototyping is vital in the journey from concept to precision-engineered product. It involves creating a preliminary version of a custom metal component before full-scale production. This process allows manufacturers to test designs, assess functionality, and identify potential issues, ultimately ensuring the final product meets specifications.

Custom metal parts prototyping commonly employs techniques like CNC machining, 3D printing, and rapid molding. These methods provide engineers and designers with invaluable insights into the feasibility and practicality of their designs. By streamlining the development process and minimizing the risk of costly errors, custom metal parts prototyping is crucial in delivering high-quality, tailor-made metal components that meet clients' unique needs across various industries.

Importance of Prototyping in Custom Metal Parts Manufacturing

Prototyping holds a paramount role in the realm of custom metal parts manufacturing. It is a strategic bridge between conception and production, offering manufacturers invaluable benefits. Firstly, prototyping allows for a meticulous evaluation of designs, ensuring that intricate custom metal components meet exact specifications. Through this iterative process, potential flaws can be identified and rectified early, saving time and resources in the long run.

Moreover, prototyping promotes innovation by providing a tangible platform for testing new ideas and materials. This experimentation fosters creativity and often leads to the development of cutting-edge custom metal parts. Ultimately, custom metal parts manufacturers benefit from enhanced quality control, minimized errors, and a streamlined production process. The result is the creation of superior, tailor-made metal components that precisely meet the unique requirements of their clients across diverse industries.

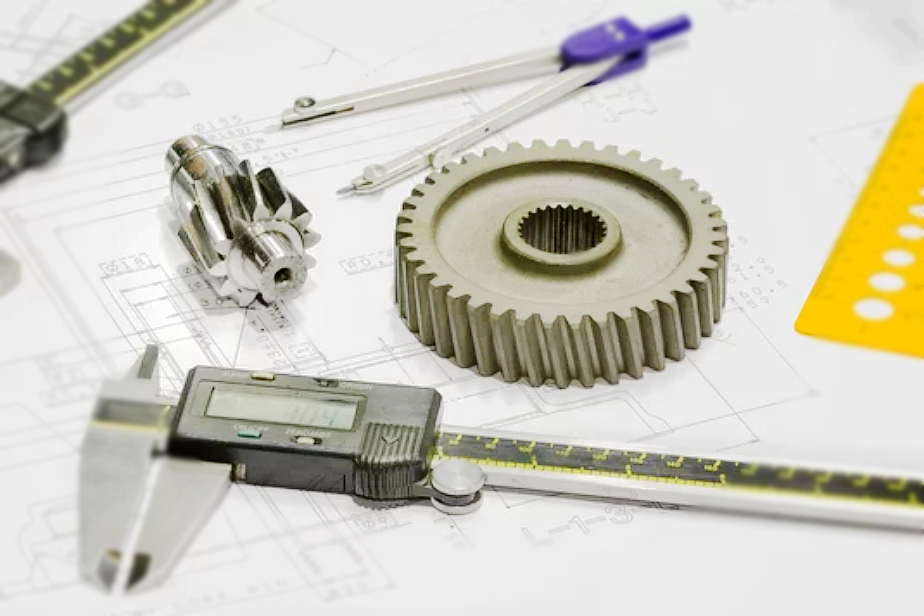

CNC Machining Prototyping

CNC (Computer Numerical Control) machining is a highly efficient prototyping method in custom metal parts manufacturing. At Neway, our dedication to precision and innovation is exemplified through this cutting-edge technique. CNC machining involves computerized systems to control machinery and create intricate, custom components. It's a pivotal step in the journey from design to production.

CNC machining is favored in custom metal parts manufacturing due to its exceptional accuracy, rapid turnaround times, and versatility. Neway excels in harnessing the power of CNC machining to craft custom steel, titanium, and brass parts with precision and finesse, providing our customers with top-notch products. For those seeking rapid prototyping and impeccable quality, CNC machining remains the ideal choice, underscoring our commitment to delivering excellence in custom metal fabrication.

Advantages of CNC Machining

CNC machining is pivotal in custom metal parts prototyping, offering several distinct advantages. Firstly, its precision is a boon for manufacturers like Neway. With CNC technology, the intricate designs of custom steel, titanium, and brass parts are executed impeccably. This precision ensures that every component is manufactured to exact specifications, meeting the stringent demands of Neway's discerning clientele.

Furthermore, CNC machining provides unmatched versatility and efficiency. This technique is adept at crafting custom metal components swiftly, accommodating the tight schedules often demanded by clients. By harnessing CNC machining, Neway solidifies its reputation as a top-tier custom metal parts manufacturer, delivering precision, speed, and quality in every product. It attracts more customers and elevates Neway's standing in the highly competitive custom metal fabrication industry.

CNC Machining Examples

In a compelling real-world example, Neway, a prominent custom metal parts manufacturer, harnessed the power of CNC machining to revolutionize the production of custom steel components. A client in the aerospace industry sought to create a complex titanium bracket for their next-generation aircraft. Neway's expertise in CNC machining came to the fore, enabling them to prototype this intricate part with exceptional precision rapidly.

The CNC-machined titanium bracket met the client's stringent design specifications and exceeded expectations regarding durability and performance. This successful collaboration between Neway and the aerospace industry exemplifies how CNC machining can seamlessly translate conceptual designs into tangible, high-quality custom metal parts, establishing Neway as a leading force in custom metal parts manufacturing. Such real-world success stories reinforce the significance of CNC machining in the domain of custom metal part prototyping.

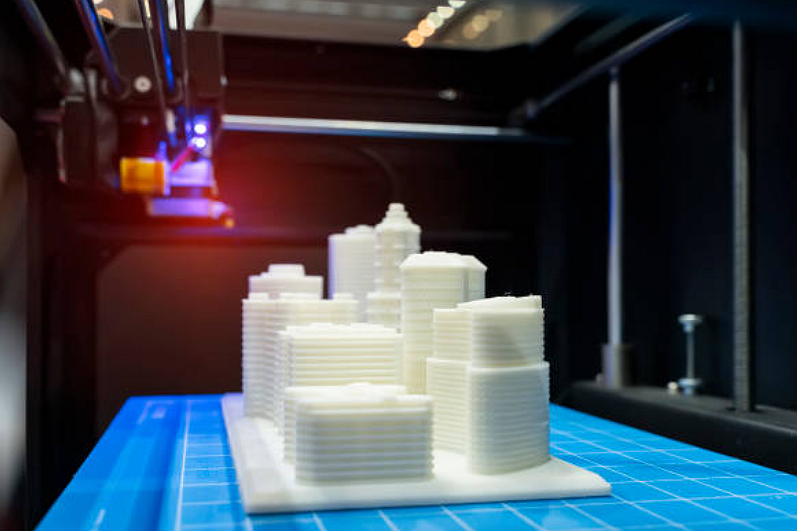

3D Printing Prototyping

3D printing, often hailed as the future of manufacturing, has significantly impacted the world of custom metal parts. As a production engineer at Neway, a leading custom metal parts manufacturer, I'm excited to share insights into this innovative technology's application in our industry. In recent years, 3D printing has emerged as a game-changer, enabling us to craft intricate custom metal components with unprecedented precision.

Traditional manufacturing methods like metal injection molding (MIM) and die casting have their merits, but 3D printing offers unique advantages. It allows rapid prototyping, ensuring custom parts are perfectly tailored to specific needs. Moreover, it minimizes material waste and reduces production lead times, making it a sustainable and cost-effective solution. At Neway, we have seamlessly integrated 3D printing into our custom metal parts manufacturing, giving our clients a cutting-edge, efficient, and eco-friendly approach. So, whether you require custom steel, titanium, or brass parts, 3D printing is revolutionizing the way we create metal components, and Neway is at the forefront of this exciting transformation.

Benefits and Limitations of 3D Printing for Prototyping

3D printing offers numerous benefits for prototyping in custom metal parts. As a production engineer at Neway, specializing in custom metal components, I've witnessed firsthand the advantages it brings to our industry. Firstly, 3D printing allows for swift and cost-effective prototyping. It significantly reduces the lead time for creating prototypes, which is crucial when time is of the essence in product development. Additionally, this technology offers the ability to easily create intricate and complex designs, which may be challenging or costly, using traditional methods like metal injection molding.

However, it's important to note that 3D printing also has limitations. While it's ideal for prototyping, it may not always be the best choice for high-volume production due to slower production speeds than die-casting methods. Furthermore, the material limitations of 3D printing can be a constraint when working with certain metals or alloys. At Neway, we recognize these factors and leverage 3D printing strategically in our custom metal parts manufacturing, maximizing its benefits while choosing traditional methods when they are better suited.

Case Study: 3D Printed Metal Parts

In a remarkable case study, Neway, a renowned custom metal parts manufacturer, demonstrated the immense potential of 3D printing for efficient prototyping. A client approached Neway with a complex custom steel part project that required intricate design and rapid development. Leveraging 3D printing, we transformed their concept into a tangible prototype, reducing lead times significantly. This technology enabled us to iterate and refine the design swiftly, ensuring the final product met the client's specifications.

The success of this case study underscores the advantages of 3D printing in custom metal parts manufacturing. It accelerates the prototyping process and facilitates the creation of intricate and tailored designs. Neway's commitment to harnessing cutting-edge technologies ensures that clients receive the best solutions for custom steel, titanium, or brass parts. This case study exemplifies our dedication to providing innovative, efficient, top-quality custom metal components.

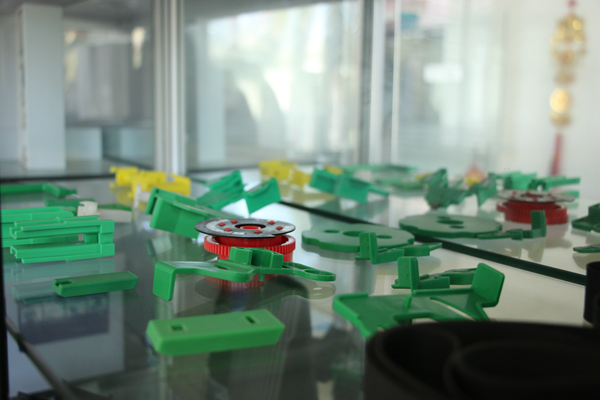

Rapid Molding Prototyping

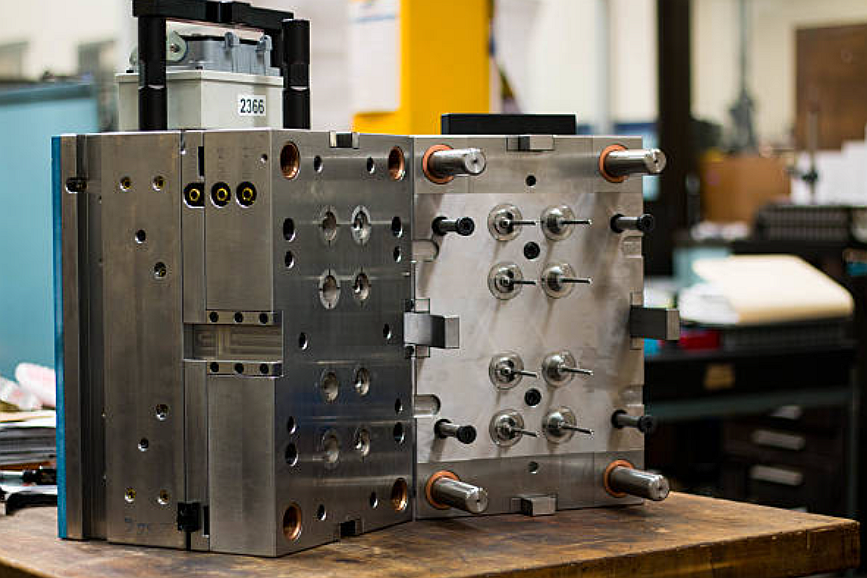

Rapid molding is a pivotal stage in custom metal parts manufacturing, particularly in prototyping. Neway, a renowned custom metal parts manufacturer, excels in this vital process. Rapid molding refers to the swift creation of prototype parts using various advanced techniques such as Metal Injection Molding (MIM), Ceramic Injection Molding (CIM), and Powder Compression Molding (PCM).

At Neway, we've mastered the art of rapid molding to expedite the transition from design to production. This streamlined approach significantly reduces lead times and costs, providing our clients with a competitive edge. By leveraging the power of custom metal parts manufacturing, Neway ensures that your unique specifications and design concepts are realized swiftly and efficiently, making us the top choice in the industry.

How Rapid Molding Compares to Other Prototyping Methods

Rapid molding stands out as a superior prototyping method compared to traditional techniques. At Neway, a leading custom metal parts manufacturer, we've harnessed the advantages of rapid molding, such as Metal Injection Molding (MIM), Ceramic Injection Molding (CIM), and Powder Compression Molding (PCM), to offer our clients unmatched benefits.

In contrast to conventional prototyping methods, rapid molding excels in speed, precision, and cost-efficiency. Neway's dedication to innovation and cutting-edge technology ensures that your custom metal components are crafted with utmost precision and delivered swiftly. This method accelerates the development cycle and allows cost-effective design iterations, positioning Neway as the go-to choice for clients seeking top-tier custom metal parts prototyping.

Case of Rapid Molding

In custom metal parts manufacturing, efficiency and precision are paramount. At Neway, a leading custom metal parts manufacturer, we have honed the art of rapid molding to meet the exacting demands of our clients.

Imagine a client requiring a set of intricately designed custom steel components for a cutting-edge aerospace project. Time is of the essence, and precision is non-negotiable. Neway's rapid molding capabilities come to the forefront. Using our Metal Injection Molding (MIM) and state-of-the-art technology, we swiftly transform the client's design into reality. The MIM process allows for intricate geometries and high material density, meeting the strictest aerospace standards. Our commitment to custom metal parts manufacturing excellence ensures we meet and exceed our client's expectations.

Choosing the Right Prototyping Method

Selecting the proper prototyping method is crucial in custom metal parts manufacturing. Your choice can significantly impact the development process, lead times, and, ultimately, the success of your project. As a production engineer at Neway, you have a unique perspective, and I'm here to help you provide a professional and detailed yet concise guide.

Understand Your Project's Requirements:

Before diving into prototyping, it's essential to understand your project's specific needs thoroughly. Consider materials type (custom steel, titanium, brass, etc..), design complexity, and intended use.

Metal Injection Molding (MIM):

The MIM process is ideal for producing complex custom metal components with tight tolerances (+/-0.02 mm for blanks). This method offers exceptional design freedom, making it suitable for mass-producing small metal intricate parts.

MIM can manufacture custom metal parts made of various metal materials, including high melting point metals such as tungsten alloy, nickel-cobalt alloy, Etc. Compared with investment casting, MIM parts have higher precision and surface effects.

Ceramic Injection Molding (CIM):

If your project requires parts for high-temperature environments or excellent electrical insulation, CIM is a great choice because CIM ceramic parts have high-temperature resistance, hardness, and wear resistance.

CIM is suitable for mass-producing small, complex ceramic parts like metal injection molding.

Powder Compression Molding (PCM) :

PCM is cost-effective and suitable for projects where traditional metalworking methods might be too expensive. It's often used for simpler custom metal parts.

Since the mold clamping mechanism of PCM is an upper and lower clamping mechanism, it can only produce relatively simple metal or ceramic parts and is unsuitable for parts with undercuts or rows. But it can produce more significant parts than MIM parts.

Die Casting:

Die casting is efficient and cost-effective when you need large quantities of custom metal parts. It's commonly used in the automotive and consumer goods industries.

However, it is only suitable for metal products such as aluminum, zinc, magnesium, and copper. Compared with other casting methods, die casting has the highest precision, and the surface of die castings is the smoothest.

Sand Casting, Investment Casting, and Gravity Casting:

These casting methods are versatile and can be used for various custom metal parts, especially when intricate details are required.

Sand casting is suitable for parts with high complexity and large volumes but not very high precision and surface requirements because sand cores can create various unique structures and shapes in sand casting. Since sand casting is pressureless casting, parts with a thickness of less than 1.5mm cannot be manufactured. At the same time, because the gravel mold has a certain roughness, the surface of sand castings usually could be smoother and require further processing to obtain a smoother surface.

Labor costs are high since sand casting cannot be produced using semi-automatic equipment. Therefore, it is only suitable for small-batch production.

Compared with sand casting, gravity casting has higher output, higher precision, and higher surface roughness. Suitable for small and medium batch production.

Investment casting, also called lost wax casting, is suitable for manufacturing high melting point metals, such as carbon steel, stainless steel, copper alloy, Etc. Due to the particularity of its mold, it is suitable for manufacturing medium-volume parts.

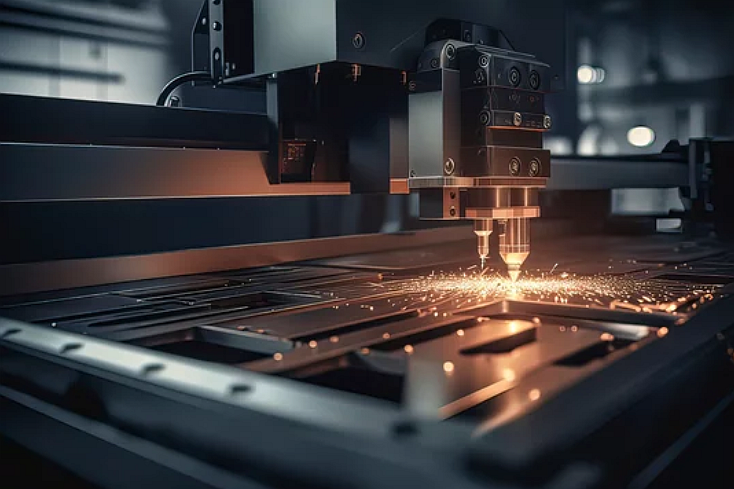

Sheet Metal Fabrication:

Sheet metal manufacturing includes laser cutting, metal bending, welding, sheet metal stamping, and other processes.

Laser cutting is ideal for creating custom steel parts with precision and speed. It's commonly used for prototyping or small-medium sheet metal fabrication.

Stamping and bending offer a cost-effective solution for simple custom metal components. They are ideal for high-volume orders.

Usually, laser cutting, bending, and welding are required simultaneously in sheet metal manufacturing. Suitable for small and medium-volume manufacturing of sheet metal parts.

Plastic Injection Molding:

If your project involves custom plastic parts, plastic injection molding is the go-to method. It's widely used in various industries, from medical devices to consumer goods. It is suitable for mass manufacturing plastic parts, while proofing usually uses CNC, rapid molding, or 3D printing.

The injection step in metal injection molding is derived from plastic injection molding. It can produce more complex structures and is suitable for mass production of plastic parts, but the initial mold development cost is high.

Over Molding and Insert Molding:

Over-molding and insert molding are suitable methods when your custom parts require multiple materials or components.

Over molding can combine two or more plastic parts, and insert molding can combine metal and plastic to form new parts. They can all use automated or semi-automated equipment for production operations. Therefore, labor costs are low and suitable for producing and manufacturing various parts combinations.

Neway Custom Manufacturing Capability

Neway has gradually improved the production system of basic hardware, plastic, and ceramic non-standard parts after 30 years of growth from the original CNC workshop. As well as polishing, PVD, and simple assembly lines. Provide one-stop, non-standard manufacturing services to our customers.