Warpage in Aluminum Die Casting: Causes and Solutions

Introduction

Aluminum die casting is a popular manufacturing process for producing complex, high-precision components with excellent surface finish and dimensional stability. However, warpage is a significant challenge in aluminum die casting. Warpage can lead to dimensional inaccuracies and compromised structural integrity, affecting the quality and functionality of the final product.

Addressing warpage issues is crucial to ensure that cast parts meet the stringent requirements of various industries, from automotive to aerospace. In this blog, we will delve into the common warpage problems encountered in aluminum die casting, explore their causes, and discuss practical solutions to mitigate them. By understanding and applying these strategies, manufacturers can enhance the quality and reliability of their die-cast products.

Understanding Warpage in Aluminum Die Casting

Definition of WarpageWarpage in aluminum die casting refers to a cast part's unintended distortion or deformation. This deformation occurs when different areas of the casting contract unevenly during the cooling process, leading to a mismatch in the final shape compared to the intended design.

Causes of Warpage in Aluminum Die Casting

Thermal Stresses: During the die-casting process, the rapid cooling of the molten aluminum can create significant thermal stresses within the material. These stresses can cause different sections of the part to contract at varying rates, resulting in a warpage.

Uneven Cooling Rates: If the cooling of the cast part is not uniform, it can lead to differential contraction. Areas that cool more slowly or quickly than others can warp due to the uneven distribution of thermal contraction forces.

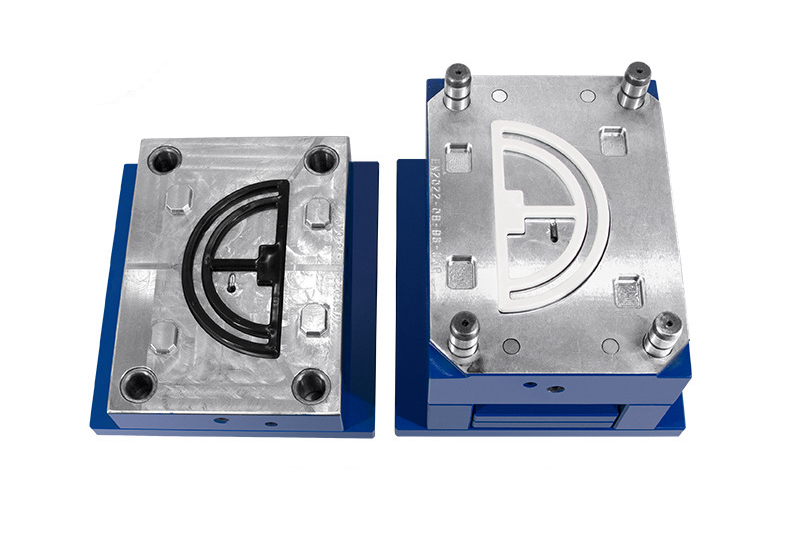

Mold Design Issues: The die mold design is crucial in how molten aluminum flows and cools. Poor mold design, such as improper gate, runner placement, or inadequate cooling channels, can contribute to warpage.

Material Properties: The specific properties of the aluminum alloy used can also influence warpage. Factors such as alloy composition, grain structure, and thermal conductivity can affect the material's behavior during cooling and solidification.

Common Warpage Problems

Description of Typical Warpage IssuesWarpage in aluminum die casting manifests in various forms, each affecting the final product differently. The most common types of warpage include:

Bowing occurs when the casting bends along its length, creating a convex or concave shape. Bowing can be particularly problematic for long, flat components where straightness is critical.

Twisting: Twisting refers to the torsional deformation where different casting sections rotate relative to each other. It can lead to misalignment and difficulty in assembly with other components.

Distortion: General distortion involves complex, uneven deformation of the casting, which can affect multiple dimensions and angles. This type of warpage often requires comprehensive corrective measures.

Examples of How Warpage Affects the Final ProductWarpage can severely impact the quality and usability of die-cast aluminum parts in various ways:

Dimensional Inaccuracies: Warped parts often fail to meet the precise dimensional specifications required for proper fit and function. It can result in parts that do not fit correctly in assemblies, leading to increased wear, noise, and even failure in use.

Compromised Structural Integrity: Warpage can introduce unwanted stresses and weaknesses in the material, reducing the overall strength and durability of the component. It is especially critical in applications where structural integrity is paramount, such as automotive and aerospace industries.

Factors Contributing to Warpage

Influence of Cooling RatesOne of the primary factors contributing to warpage in aluminum die casting is the cooling rate. Different casting sections cool and contract at varying rates when the cooling process is not uniform. This differential contraction creates internal stresses, leading to warpage. Rapid cooling can cause casting areas to contract more quickly. At the same time, slower cooling sections lag, resulting in bending, twisting, or other distortions.

Impact of Mold, DesignThe design of the die mold is crucial in determining the cooling rate and flow of molten aluminum. Several aspects of mold design can significantly impact warpage:

Gate and Runner System: The placement and design of gates and runners influence molten aluminum flow into the mold cavity. Poorly designed systems can lead to uneven filling and cooling, increasing the risk of warpage.

Mold Cavity Alignment: Misalignment of mold cavities can create areas of differential stress during cooling. Ensuring precise alignment helps maintain uniform contraction and reduces the chances of warpage.

Cooling Channels: Properly designed cooling channels within the mold help dissipate heat uniformly. Inadequate cooling channel design can result in hot spots and uneven cooling, leading to warpages.

Role of Material, PropertiesThe properties of the aluminum alloy used in die casting also play a significant role in warpage. Key material factors include:

Alloy Composition: Different aluminum alloys have varying thermal expansion and contraction rates. Selecting an alloy with properties that match the specific requirements of the casting process can help minimize warpage.

Grain Structure: The aluminum's grain structure affects how it reacts to thermal stresses. Fine, uniform grains are generally more resistant to warpage than coarse, irregular grains. Controlling the solidification process to achieve the desired grain structure is essential in preventing warpage.

Preventative Measures for Warpage

Optimal Mold Design Strategies

Uniform Wall Thickness: Ensuring uniform wall thickness in the design of the die-cast part is essential. Variations in thickness can lead to uneven cooling and contraction, which primarily causes warpage. Maintaining consistent wall thickness allows thermal stresses to be distributed more evenly, reducing the risk of deformation.

Proper Gate Placement: The placement of gates, which control the flow of molten aluminum into the mold, significantly impacts the cooling rate and uniformity. Properly positioned gates can fill and cool the mold cavity, minimizing the potential for warpage. Gates should be placed in areas that promote smooth flow and reduce turbulence.

Controlled Cooling Techniques

Gradual Cooling Methods: Gradually cooling techniques can help prevent warpage by allowing the casting to cool at a controlled rate. It can be achieved through various methods, such as using insulated covers or controlled cooling environments to slow the cooling process.

Use of Cooling Channels: Incorporating well-designed cooling channels within the mold can ensure uniform cooling. These channels help dissipate heat evenly throughout the casting, reducing the risk of differential contraction and subsequent warpage. Properly designed cooling channels are crucial for maintaining consistent temperature gradients.

Material Selection and Treatment

Choosing the Right Aluminum Alloy: Selecting an appropriate aluminum alloy minimizes warpage. Some alloys have better resistance to thermal stresses and are less prone to deformation. Consideration should be given to the alloy's thermal expansion properties and solidification characteristics.

Heat Treatment Processes: Applying heat treatment processes to the cast part can enhance its mechanical properties and reduce residual stresses. Processes such as annealing or solution heat treatment can relieve internal stresses, making the material less susceptible to warpage. Heat treatment can also improve the aluminum's grain structure, further reducing the risk of deformation.

Warpage Correction Techniques

Post-Casting Straightening Methods

Thermal Straightening: Thermal straightening involves applying controlled heat to specific areas of the warped casting to relieve internal stresses and correct deformations. Manufacturers can manipulate the material properties by carefully heating and cooling the part to return the casting to its intended shape. This technique requires precise temperature and heating duration control to avoid introducing new stresses or exacerbating existing warpages.

Mechanical Straightening: Mechanical straightening uses physical force to correct the warpage. It can be done using hydraulic presses, clamps, or specialized straightening tools that apply pressure to the warped areas. While this method can effectively correct minor warpages, it must be done carefully to avoid damaging the casting or inducing new stresses.

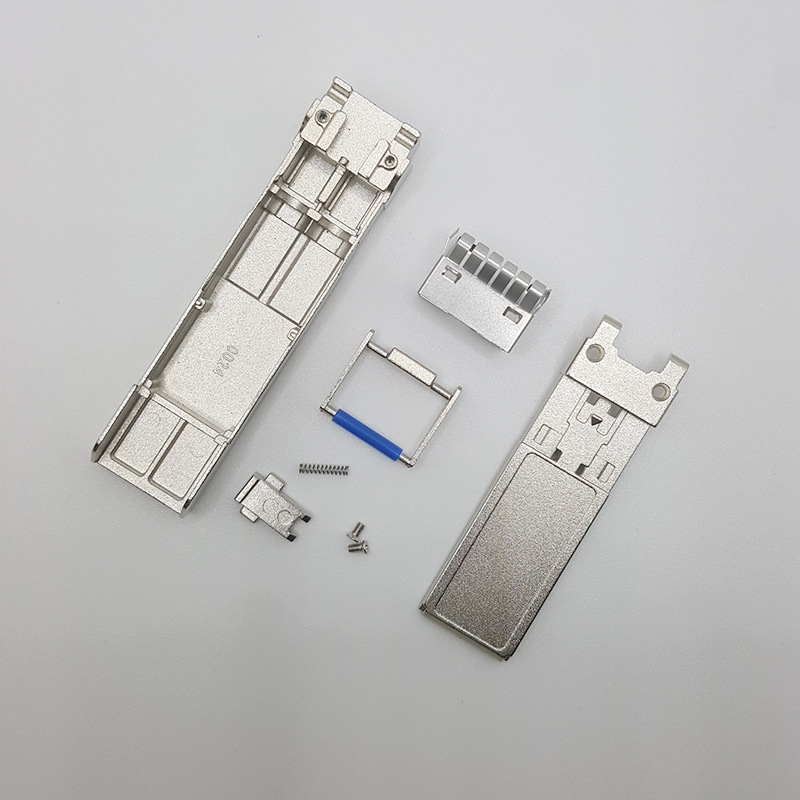

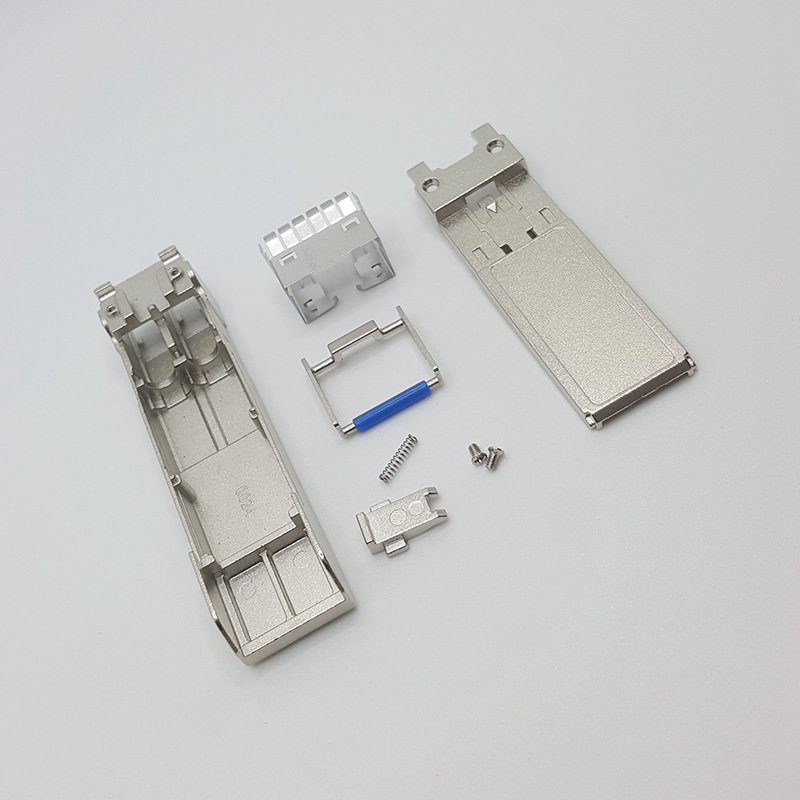

Precision Machining to Correct Minor Warpage

For castings with minor warpages, precision machining can be an effective solution. It involves machining the warped areas to return the part to its specified dimensions. Techniques such as CNC milling, grinding, and turning can remove excess material and achieve the desired shape and tolerance. Precision machining is particularly useful for high-precision components where minor dimensional inaccuracies can impact performance.

Real-Life Case Study: A Successful Warpage Correction Project

A case study illustrating the successful application of warpage correction techniques can provide valuable insights. Consider a scenario where an automotive component experienced significant warpage due to uneven cooling during die-casting. The manufacturer implemented a combination of thermal straightening and precision machining to correct the warpage:

Initial Assessment: The part was thoroughly inspected to determine the extent and nature of the warpage. Measurements were taken to identify specific areas of deformation.

Thermal Straightening: Controlled heat was applied to the warped sections of the casting, followed by gradual cooling. This process relieved internal stresses and reduced the overall warpage.

Precision Machining: After thermal straightening, the part underwent precision machining to achieve the final dimensional specifications. CNC milling was used to remove excess material and ensure tight tolerances.

Quality Assurance: The corrected part was subjected to rigorous quality checks to verify dimensional accuracy and structural integrity. The final product met all specifications and performed as required in its intended application.

Best Practices for Minimizing Warpage

Design Considerations

Avoiding Sharp Corners: Sharp corners in die-cast designs can create stress concentrations, leading to warpage. Designing with rounded corners and fillets can help distribute stresses evenly throughout the part, reducing the likelihood of deformation. Additionally, rounded corners facilitate a better-molten aluminum flow, leading to more uniform cooling.

Ensuring Uniform Section Thickness: Variations in section thickness can cause uneven cooling rates, leading to differential contraction and warpage—design parts with consistent wall thickness to promote uniform cooling and reduce internal stresses. If variations are necessary, gradual transitions between thick and thin sections should be implemented to minimize stress concentrations.

Process Control Measures

Consistent Monitoring of Temperature and Cooling Rates: Maintaining tight control over the temperature of the molten aluminum and the cooling rates is crucial in preventing warpage. Use advanced monitoring systems to track and adjust temperatures and cooling rates throughout the casting process. It ensures that the casting cools uniformly, reducing the risk of deformation.

Regular Maintenance of Molds: Well-maintained molds are essential for consistent and accurate casting. Regularly inspect and maintain molds to ensure they are free from wear and damage. Proper maintenance includes checking for alignment, cleaning cooling channels, and ensuring that gates and runners function correctly. Well-maintained molds contribute to uniform cooling and reduce the chances of warpage.

Additional Tips for Minimizing Warpage

Preheating Molds: Preheating the die molds before casting can help reduce thermal shock and promote uniform cooling. This practice minimizes the temperature difference between the molten aluminum and mold, reducing the likelihood of warpage.

Using Simulation Software: Employing advanced simulation software can help predict potential warpage issues before production. These tools can simulate the casting process, identify areas prone to warpage, and allow design adjustments to mitigate these issues.

Implementing Quality Control Procedures: Establish rigorous quality control procedures to monitor and address warpage throughout the casting process. Regular inspections and measurements can help in the early detection of warpage, allowing for timely corrective actions.