Unlocking Complex Geometries with Investment Castings in Modern Industries

Introduction

Introduction

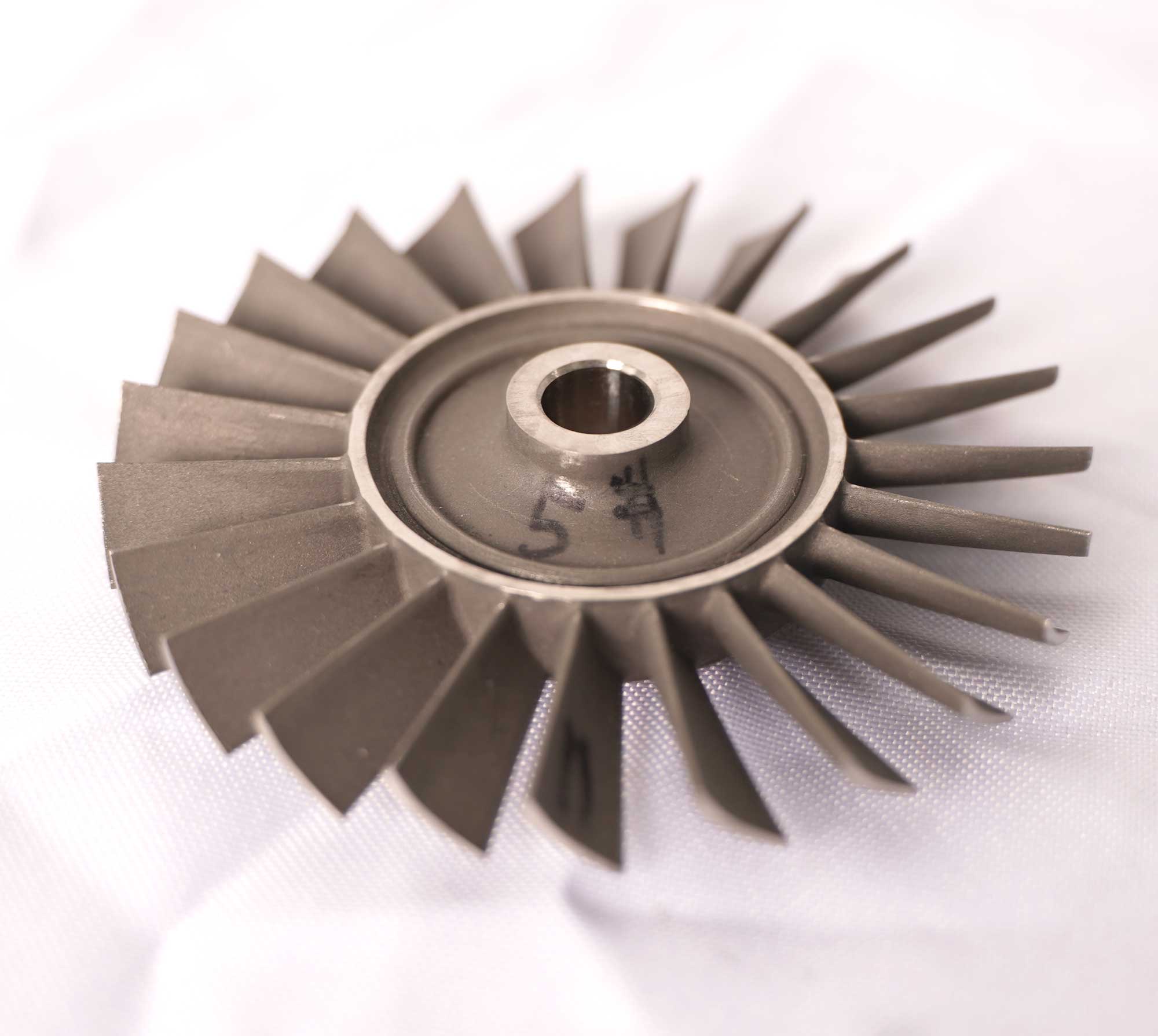

Investment casting, traditionally known as lost wax casting, has significantly evolved, becoming a favored manufacturing method across multiple industries. Renowned for precision and its ability to replicate intricate designs, this casting method uniquely addresses complex geometries that other metal casting processes find challenging.

What is Investment Casting?

Investment casting is an ancient manufacturing technique dating back thousands of years, initially utilized for jewelry and detailed metal artworks. Modern investment casting involves creating wax models, coating these in ceramic material, melting out the wax, and then pouring molten metal into the ceramic molds. Once cooled, the ceramic shells are removed, leaving intricately detailed metal components that require minimal post-processing.

Why Choose Investment Casting for Complex Geometries?

Investment casting is particularly suitable for complex shapes due to several critical advantages:

High Precision and Accuracy: Ceramic molds allow fine detail reproduction, offering superior accuracy unmatched by traditional casting methods.

Complex Internal and External Details: Enables intricate designs, internal passageways, undercuts, thin walls, and detailed features, with minimal secondary machining required.

Reduced Post-Processing Needs: Delivers near-net-shape products, significantly reducing the need for secondary machining or finishing, ultimately saving on production costs.

Applications of Investment Casting Across Modern Industries

Investment casting serves numerous diverse industries:

Aerospace: Engine components, turbine blades, and structural parts demanding precise tolerances and material integrity.

Automotive: High-performance components, including engine valves, transmission parts, and turbocharger components, require exceptional detail and strength.

Consumer Electronics: Precision connectors, brackets, and electronic device casings require accuracy and intricate shapes.

Medical: Surgical tools, implants, and precision medical devices, where precision and biocompatibility are essential.

Energy and Industrial Equipment: Parts such as pump housings, valves, and specialized equipment components demand robustness and exact tolerances.

Advantages of Investment Casting

Investment casting delivers several distinct advantages:

Superior Surface Finish Quality: Produces smooth surfaces, reducing the need for additional finishing, thereby lowering production costs and time.

Complex Geometries Easily Achieved: Facilitates highly intricate internal passages and external features in a single production step, without requiring multiple assemblies.

Material Versatility: Allows manufacturers to choose from various materials, optimizing components for specific mechanical, thermal, or chemical requirements.

Material Choices in Investment Casting

Investment casting is compatible with diverse materials, each suitable for specific applications:

Cast Aluminum: Lightweight, corrosion-resistant, ideal for automotive and aerospace applications.

Cast Stainless Steel: Highly durable, corrosion-resistant, and suitable for demanding industrial and medical equipment.

Cast Titanium: Exceptional strength-to-weight ratio and biocompatibility, perfect for medical implants and aerospace parts.

Nickel-Based Alloys: Outstanding heat and corrosion resistance, frequently used in aerospace engine components and industrial machinery.

Copper Alloys & Superalloys: Specialized materials selected for unique mechanical, electrical, or thermal properties in precision applications.

Key Considerations and Challenges

Despite numerous benefits, investment casting does involve some challenges:

Higher Initial Costs: Investment casting requires upfront investment in tooling and mold creation, making it less suitable for very low-volume productions or prototyping.

Complex Process Management: Achieving complex shapes demands careful mold design and precise process control to avoid dimensional inaccuracies or casting defects.

Production Time Considerations: Longer lead times may result from multi-step processes, though offset by reduced post-processing and higher-quality outputs.

Future Trends and Sustainability

The future of investment casting is bright, driven by advancements such as:

Eco-Friendly Manufacturing: Increased emphasis on using recyclable materials and environmentally sustainable casting processes to reduce waste and lower environmental impact.

Innovations in Digital Manufacturing: Integration with Industry 4.0 technologies, including automation, IoT, and real-time quality management, to enhance efficiency, precision, and productivity in casting processes.

Additive Manufacturing Integration: Combining investment casting with 3D printing technologies to rapidly prototype wax patterns or molds, offering unprecedented flexibility and reduced lead times.

Conclusion

Investment casting uniquely addresses manufacturing needs for precision, complexity, and high-quality finishes. Its versatility in handling intricate geometries and a wide range of materials makes it indispensable for industries requiring precise, durable, and complex components. As sustainable practices and technological innovations continue to develop, investment casting will remain crucial in driving manufacturing excellence and innovation.

FAQs:

What makes investment casting ideal for creating complex geometries?

What are the commonly used materials in investment casting?

Which industries benefit most from investment casting? I

Can investment casting accommodate large production volumes efficiently?

Are there specific limitations or challenges associated with investment casting?