Revolutionizing Prototyping and Production with Rapid Molding Techniques

Introduction

In modern manufacturing, rapid molding methods are redefining the possibilities of prototyping and production by significantly reducing lead times and enabling swift iterations. Employing technologies such as silicone molding, rapid injection molding, and 3D printed prototypes, companies achieve a degree of customization previously unattainable with conventional processes. This innovative approach enhances flexibility across industries, driving efficiency and customization while fostering ongoing innovation.

1. Overview of Rapid Molding Techniques

What is rapid molding?

Rapid molding involves creating molds quickly for accelerated prototyping and limited-run manufacturing. It significantly reduces the time required for mold fabrication by leveraging advanced manufacturing techniques, including injection molding and additive-based tooling, enabling the cost-effective production of custom parts.

Traditional molding vs. rapid molding

Traditional mold creation methods typically require lengthy, costly processes involving substantial tooling investments. In contrast, rapid molding drastically reduces the mold development cycle, allowing manufacturers to quickly and economically produce small volumes of custom components, frequently utilizing advanced plastic injection molding technologies for versatility and efficiency.

Common rapid molding methods

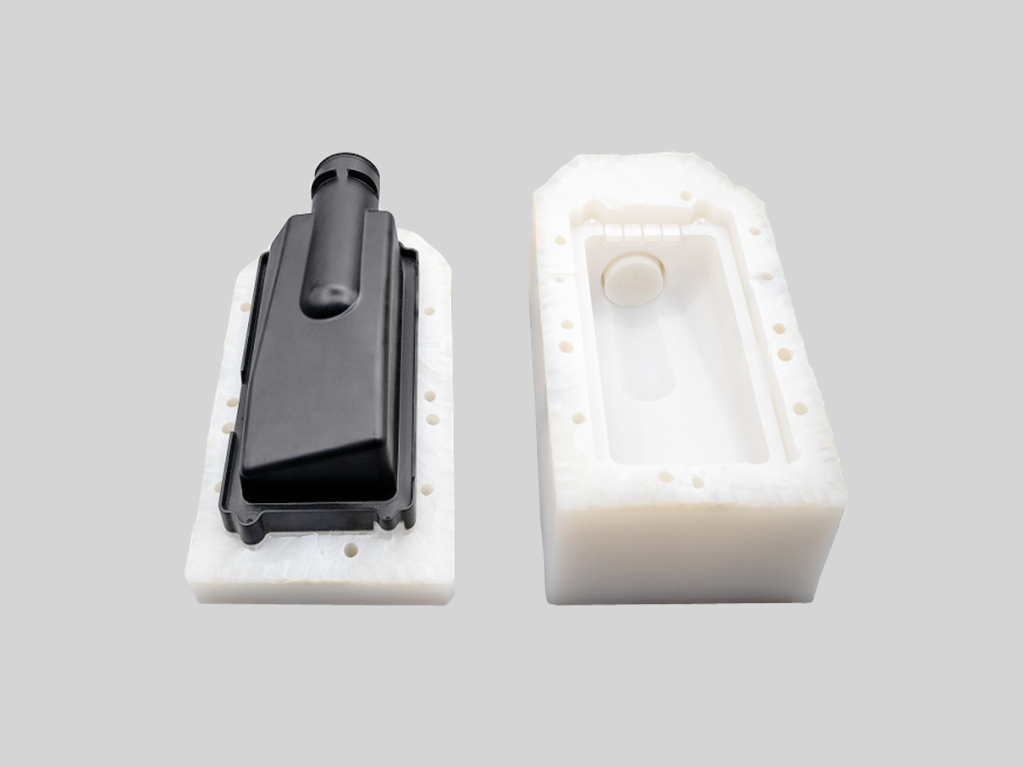

Silicone molding: Ideal for producing small batches quickly, this technique uses silicone molds to cast precise prototypes, commonly employing robust plastics such as polycarbonate for increased durability.

3D printed molds: Leveraging additive manufacturing allows businesses to produce prototype molds swiftly, enabling rapid iterations and testing at lower costs.

Rapid injection molding: Utilizes efficient mold production processes to enable fast production runs, supporting both prototyping and limited production while maintaining high-quality molded parts.

2. Automotive Industry

Automotive manufacturers extensively utilize rapid molding, accelerating prototyping and expanding the scope for customization and flexibility.

Accelerated prototyping and development

Rapid molding dramatically speeds up automotive component prototyping, significantly cutting down the design-to-production timeline. Automotive engineers quickly test and refine components, like engine housings or interior panels, ensuring rapid market responsiveness.

Customized automotive components

Rapid molding techniques facilitate cost-effective small-batch manufacturing of custom automotive components, such as unique dashboards, personalized interior features, and high-precision lightweight components, effectively addressing niche market demands.

Lightweight and durable designs

Rapid molding supports automotive lightweighting efforts by enabling the creation of intricately structured parts, thereby reducing vehicle weight and improving fuel efficiency. This is often achieved using durable materials like cast aluminum alloys, providing optimal strength-to-weight ratios.

2. Medical and Healthcare Applications

Rapid molding significantly impacts medical manufacturing, providing solutions tailored precisely to patient-specific requirements and medical standards.

Efficient medical prototyping

Healthcare providers benefit from rapid molding’s capability to quickly create functional prototypes for medical devices. These rapid prototypes, from surgical tools to diagnostic instruments, streamline regulatory processes and accelerate patient access to new medical innovations.

Customized implants and prosthetics

Rapid molding produces patient-specific components such as custom prosthetics, surgical instruments, and orthopedic implants, employing biocompatible materials like MIM titanium alloys to ensure precision and patient compatibility.

Efficient medical device manufacturing

Rapid molding significantly reduces lead times for medical device housings and functional components, facilitating prompt responses to urgent medical needs and dynamic healthcare demands. This responsiveness enables faster innovation and more efficient medical product lifecycles through advanced plastic injection molding processes.

3. Consumer Products Manufacturing

Consumer product manufacturers rely on rapid molding for their ability to swiftly adapt to market changes and consumer preferences.

Fast product iterations and customization

Rapid molding supports rapid prototyping and testing, enabling businesses to refine designs quickly based on real-time consumer feedback. This accelerates market entry for products like custom electronics, tailored consumer accessories, and personalized plastic components, enhancing customer satisfaction.

Economical small-batch production

Rapid molding economically produces limited quantities of highly customized consumer goods, avoiding high tooling costs of traditional methods. Businesses can test consumer interest and iterate rapidly, often incorporating durable materials such as ABS-PC plastics.

Enhanced design flexibility

Designers utilize rapid molding to experiment freely with product aesthetics and functionalities, using innovative materials and customized surface treatments to create distinctive products and unique market positioning.

4. Aerospace and Defense Solutions

Aerospace and defense sectors extensively employ rapid molding to accelerate component testing, validation, and innovation.

Quick turnaround of complex parts

Rapid molding technologies produce complex aerospace parts such as engine components, brackets, and lightweight structural elements swiftly and economically, utilizing specialized materials like nickel-based superalloys to achieve the required mechanical properties.

Agile design and production cycles

The aerospace sector leverages rapid molding to swiftly accommodate evolving design specifications, enabling timely iterations and testing of new concepts while employing advanced ceramic materials to meet high-performance requirements.

Reduced costs for prototyping and validation

Rapid molding significantly reduces prototyping costs, enabling aerospace engineers to economically test and refine parts, frequently combined with precision surface treatment techniques to ensure optimal functionality and durability.

5. Electronics Industry Innovation

Rapid molding drives innovation in electronics manufacturing, promoting faster prototyping and versatile design options.

Accelerated electronic device prototyping

Rapid molding expedites developing and validating new electronic components, significantly reducing time-to-market for innovative products and streamlining the prototyping process.

Precise casings and housings

Rapid molding enables intricate and optimized designs for electronic housings and internal components, offering superior functionality, aesthetic appeal, and effective thermal management properties.

Customization for niche markets

Additive manufacturing and rapid molding allow electronics manufacturers to economically produce specialized small batches tailored to niche market needs, thus enhancing product differentiation and customer satisfaction.

Conclusion

Rapid molding represents a transformative leap in prototyping and manufacturing, empowering diverse industries—from automotive and healthcare to consumer products, aerospace, and electronics—to achieve higher efficiency, cost savings, and market responsiveness. As rapid molding technology advances, its capabilities and applications will continue expanding, further reshaping modern manufacturing landscapes with customized, efficient, and innovative solutions.

FAQs:

What materials are commonly used in rapid molding processes?

How quickly can parts be produced using rapid molding techniques?

Is rapid molding suitable for high-volume production?

What are the cost benefits of rapid molding compared to traditional methods?

Can rapid molding produce parts with complex geometries?