Rapid Injection Molding Service: Everything You Need To Know

Introduction

Rapid Injection Molding is an advanced manufacturing process designed to quickly produce injection molded components, making it highly effective for rapid prototyping and small-scale production. Unlike traditional molding techniques, rapid injection molding leverages technologies such as rapid tooling and efficient mold creation methods to significantly reduce production time and costs. Industries prioritizing swift product development cycles use rapid injection molding to stay responsive and competitive in dynamic markets.

Understanding Rapid Injection Molding

Detailed Explanation of the Rapid Injection Molding Process

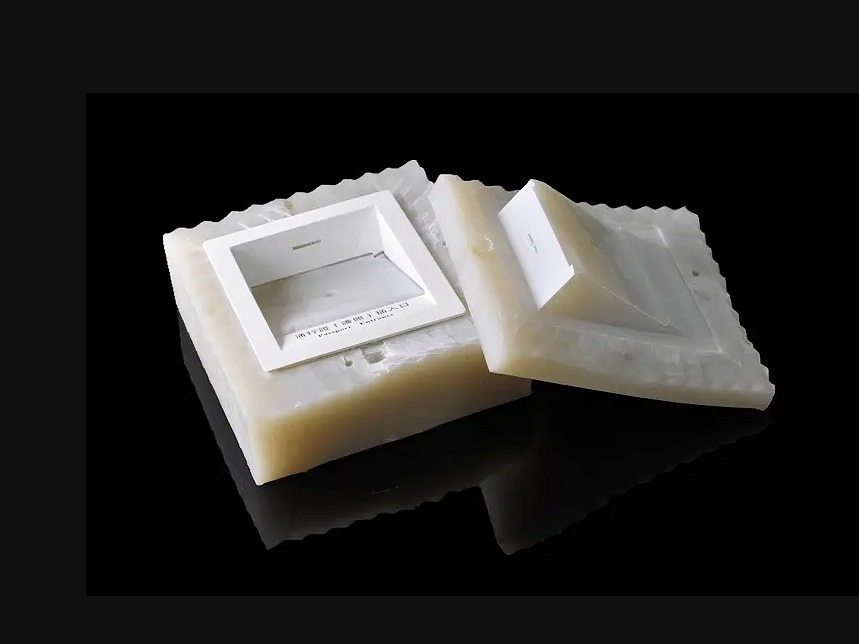

The rapid injection molding process involves injecting heated thermoplastic materials into custom mold cavities, where the material cools and solidifies to form precise, functional components. Unlike traditional molds, rapid molding typically employs molds created from aluminum or composite materials using CNC machining or additive manufacturing, drastically accelerating mold production.

The primary stages include:

Mold Design and Tooling: Rapid mold creation via CNC machining or 3D printing technologies.

Injection: High-pressure injection of molten materials into molds.

Cooling: Solidification of the injected material to the mold’s precise shape.

Ejection: The finished custom molded parts are ejected, inspected for quality, and prepared for final use.

Differences between Traditional and Rapid Injection Molding

Traditional injection molding typically relies on steel molds, which can take weeks or months to fabricate. In contrast, rapid injection molding significantly reduces timelines by using aluminum or composite molds, making it highly suitable for prototype production and quick-turnaround projects.

Materials Commonly Used

Materials frequently employed in rapid injection molding include durable plastics such as ABS, Polycarbonate (PC), Nylon (PA), Polypropylene (PP), and Thermoplastic Elastomers (TPE). Each material has unique properties tailored to diverse industry applications, from structural strength and heat resistance to flexibility and chemical resistance.

Applications of Rapid Injection Molding

Prototyping and Low-Volume Production

Rapid injection molding is ideal for creating functional prototypes and small production batches. It enables designers and engineers to rapidly iterate designs, validate concepts, and refine product functionality efficiently before investing in long-term tooling.

Automotive Industry

In the automotive industry, rapid injection molding accelerates the development of components such as dashboard assemblies, internal brackets, connectors, and housing elements. Its speed and precision enable manufacturers to swiftly transition designs from prototypes to finished parts, streamlining automotive production cycles.

Consumer Electronics

Rapid injection molding significantly benefits the consumer electronics sector by swiftly producing components such as device enclosures, connectors, casings, and precision internal parts. This facilitates manufacturers’ ability to rapidly incorporate consumer feedback and quickly introduce product improvements to the market.

Medical Devices

Rapid injection molding supports the medical device industry by efficiently producing prototypes and small-batch components such as disposable surgical tools, medical-grade housings, and specialized equipment. The method ensures strict compliance with quality standards, biocompatibility, and precise tolerances required in medical applications.

Aerospace Components

Aerospace applications frequently utilize rapid injection molding for components requiring fast turnaround, rigorous specifications, and precise performance standards. Parts such as brackets, specialized fittings, enclosures, and interior elements benefit from the precision, speed, and high-quality finishes achievable through this method.

Key Benefits of Rapid Injection Molding

Reduced Time-to-Market

Rapid injection molding significantly reduces the product development cycle, enabling companies to transition rapidly from prototyping to full-scale production. This accelerated approach gives businesses a competitive edge, allowing them to respond to market demands promptly, introduce product improvements, and effectively manage development costs.

Cost-effectiveness for Short-Run Production

Rapid injection molding provides an economical solution for short-run and prototype productions by minimizing expensive tooling investments. Businesses can cost-effectively test market responses, validate designs, and produce limited editions or custom products without committing to costly long-term tooling solutions.

Flexibility and Adaptability

Rapid injection molding offers considerable flexibility in design iterations and adaptations. Quick mold adjustments, combined with efficient tooling methods like overmolding and insert molding, enable designers to seamlessly introduce design changes, enhancing product performance and aesthetic appeal without extensive cost implications.

Enhanced Design Iteration and Improvement

Rapid injection molding facilitates rapid design iterations and continuous improvements, empowering engineers to quickly validate product functionality, refine aesthetics, and address potential design challenges. The agility afforded by this method ensures higher product quality, reduced development risks, and more successful product outcomes.

Rapid Injection Molding vs. Other Prototyping Methods

Rapid Injection Molding vs. CNC Machining

CNC machining is highly precise but often costly and slower for producing complex geometries at higher quantities. Rapid injection molding efficiently produces complex shapes in greater volumes, delivering high-quality, repeatable results at significantly reduced costs.

Rapid Injection Molding vs. 3D Printing

While 3D printing excels in delivering design flexibility and extremely rapid prototyping, it often lacks durability and scalability. Rapid injection molding produces components with superior mechanical properties, greater durability, and suitability for functional prototypes or end-use applications requiring consistent quality and reliable performance.

Criteria for Choosing Rapid Injection Molding

Select rapid injection molding when your project involves:

Quick production of functional prototypes or end-use parts.

Economical production for small to medium-scale volumes.

Complex component geometries not easily achievable through CNC machining.

Essential material-specific performance characteristics such as flexibility, strength, and heat resistance.

Best Practices for Rapid Injection Molding

Design Guidelines for Optimal Results

Maintain uniform wall thickness to avoid warpage and minimize shrinkage during cooling.

Incorporate draft angles to facilitate easier part ejection and mold longevity.

Minimize or carefully manage undercuts and complex features.

Design with assembly, function, and manufacturability in mind.

Selecting Appropriate Materials

Select materials based on your product’s functional needs, considering critical factors such as mechanical strength, heat resistance, flexibility, and chemical resistance. Proper material selection ensures consistent performance standards and durability throughout the product's lifecycle.

Quality Control Measures

Establish rigorous quality control measures, including dimensional inspection, mechanical testing, and visual inspection, to ensure parts consistently meet design and performance specifications.

Importance of Communication and Collaboration

Clear, proactive collaboration with your rapid injection molding provider ensures efficient project execution, prevents costly design oversights, and promotes clear alignment on expectations and deliverables, significantly enhancing production outcomes.

Choosing the Right Rapid Injection Molding Partner

Factors to Consider

When selecting your injection molding partner, consider their industry experience, technical capabilities, certifications, production lead times, and ability to handle your specific material and design requirements. A well-chosen partner contributes substantially to project success.

Importance of Communication and Collaboration

Effective and transparent communication enhances efficiency, mitigates potential issues, and ensures alignment throughout your project’s lifecycle. Your ideal partner should be responsive, transparent, and committed to achieving your specific project goals.

Conclusion

Rapid injection molding continues to revolutionize prototyping and short-run manufacturing, providing unparalleled speed, cost-effectiveness, and flexibility. With ongoing advancements in technology and materials, rapid injection molding is positioned to enhance further companies' abilities to innovate, reduce costs, and respond swiftly to evolving market demands.

Related FAQs:

What materials can be used in rapid injection molding?

How quickly can rapid injection molded parts be produced?

What are the typical tolerances achievable in rapid injection molding?

Is rapid injection molding suitable for high-volume production?

What design features should be avoided in rapid injection molding?