Precision Perfected: Achieving Exacting Tolerances Through Investment Casting

Introduction

In advanced manufacturing, achieving precise dimensions is essential for product quality, reliability, and performance. Investment casting, also known as lost-wax casting, is particularly renowned for its exceptional ability to produce components with exacting tolerances. This method enables industries like aerospace and medical technology to meet critical standards, making investment casting an ideal choice for precision manufacturing.

Understanding Investment Casting

Investment casting is a detailed process involving the creation of a wax pattern coated with ceramic material. The wax melts away once the ceramic shell hardens, leaving a precise mold for molten metal. Commonly cast materials include stainless steel, aluminum alloys, titanium alloys, brass, and bronze. Investment casting offers significantly better dimensional accuracy, superior surface finishes, and the capability to produce highly intricate geometries than sand casting and die casting.

Achieving Precision and Tight Tolerances

Factors Contributing to High Precision

Achieving precise dimensions with investment casting involves meticulous control throughout the process. Accurate wax patterns, precise ceramic shell creation, and controlled metal pouring collectively contribute to tight tolerances. Each stage is carefully optimized, ensuring consistently high-quality final parts.

Techniques to Achieve Exact Tolerances

High-precision tooling, often CNC-machined, is essential for accurate wax molds. Investment casting also leverages advanced ceramic slurry and sand layering techniques alongside controlled pouring temperatures to minimize dimensional variations and achieve exact tolerances.

Importance of Design and Mold Accuracy

Detailed CAD models and sophisticated simulation tools are vital for predicting casting outcomes. Ensuring design accuracy and proper mold preparation significantly improves casting precision, enabling manufacturers to consistently meet exacting standards.

Economic and Operational Benefits

Cost-Efficiency Through Reduced Machining

Investment casting produces near-net-shape components, greatly reducing the need for additional machining operations. This cost-effective approach minimizes material waste and streamlines manufacturing processes, resulting in significant economic advantages.

Production of Complex Geometries

Investment casting enables the creation of highly complex geometries with minimal post-processing. Components traditionally requiring multiple assemblies can be manufactured as single units, reducing assembly time and costs and enhancing production efficiency.

Enhanced Product Quality and Reliability

Products created using investment casting exhibit excellent dimensional consistency and surface finish quality. These advantages directly translate into improved durability, performance, and reliability, which are critical for applications in demanding sectors like aerospace and medical manufacturing.

Real-World Applications and Case Studies

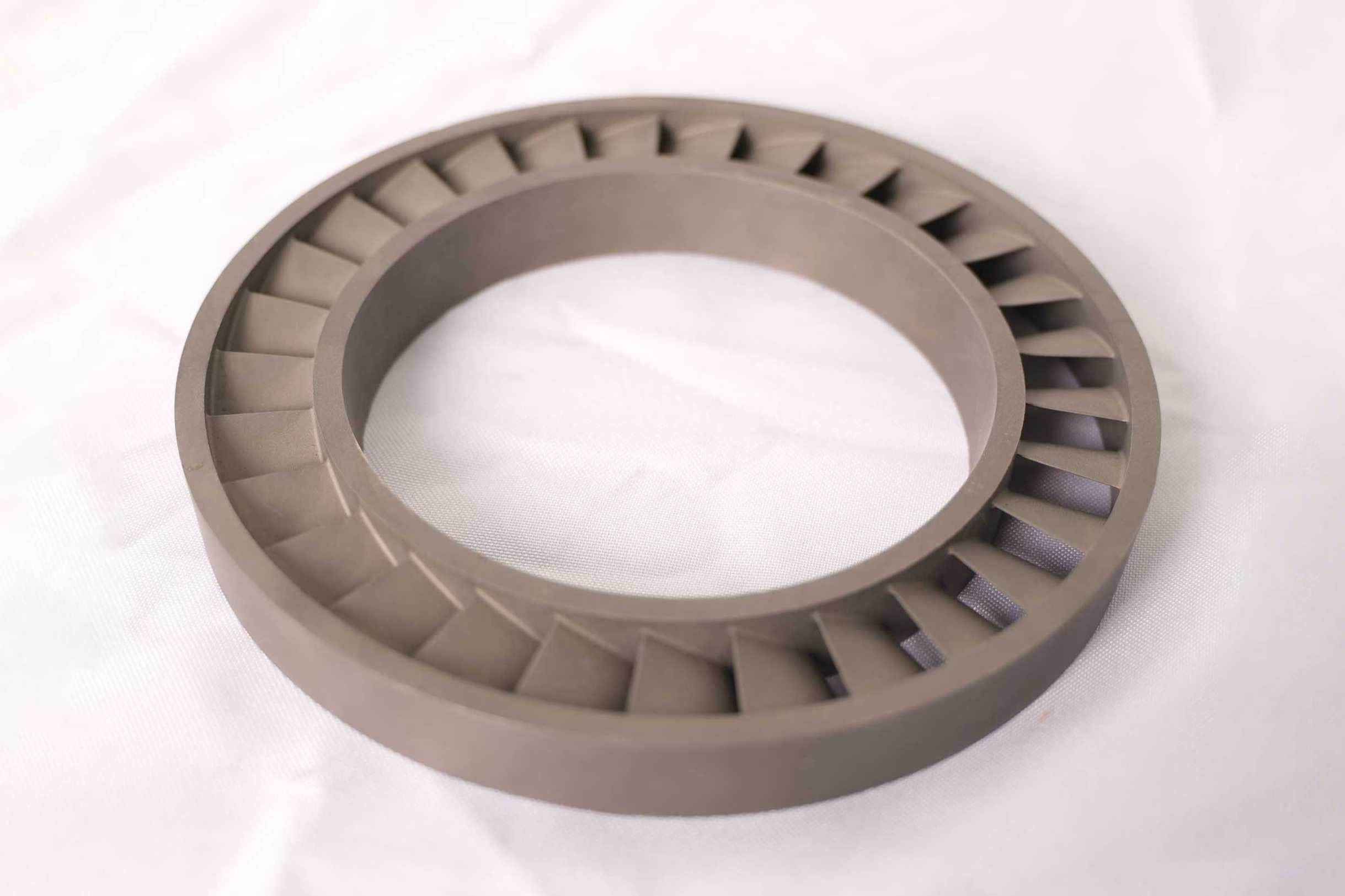

Aerospace Industry Precision Casting

The aerospace industry extensively utilizes investment casting for turbine blades, engine housings, and structural components. The precision and reliability offered by this method help aerospace manufacturers meet rigorous safety standards, enhance aircraft performance, and achieve operational efficiency.

Medical Devices and Healthcare Equipment

Investment casting's precision makes it ideal for producing medical devices and surgical instruments. This process ensures strict compliance with regulatory standards, offering superior accuracy and reliability required for sensitive applications, such as surgical tools and implants.

Automotive Precision Components

In automotive manufacturing, investment casting produces critical precision components like gears, valves, and engine parts. These parts require exacting tolerances for optimal performance and reliability, making investment casting essential to automotive engineering.

Industrial Machinery and Tool Manufacturing

Industrial sectors use investment casting to create robust and complex machinery components. This approach reduces operational downtime, enhances equipment reliability, and boosts productivity, further demonstrating the value of precision casting in industrial applications.

Overcoming Common Challenges

Typical Precision-Related Challenges

Challenges in investment casting include dimensional shrinkage, mold cracking, and metal impurities, which can affect precision. Employing rigorous quality control practices and precise casting simulation software helps mitigate these issues.

Solutions and Best Practices

Implementing advanced simulation technology, precise temperature management, and rigorous quality checks significantly reduces casting defects. Collaboration with experienced casting specialists further enhances quality control and ensures consistently accurate and reliable components.

The Role of Technology and Expert Collaboration

Working closely with skilled casting providers allows manufacturers to leverage cutting-edge technologies such as 3D modeling, robotics, and automated production, further boosting process accuracy and consistency.

Future Innovations in Investment Casting

Advances in Materials and Alloys

Innovations in alloy compositions, emphasizing improved flow properties and reduced shrinkage, will further enhance investment casting precision. Continued research into novel alloys promises more robust, precise, and high-performing components.

Impact of Automation and Digital Technologies

Integrating automation, robotics, and digital systems continues to enhance investment casting accuracy. These advancements allow tighter process controls, reduce human errors, and improve overall production efficiency, paving the way for more advanced manufacturing methods.

Emerging Market Applications and Innovations

Investment casting is increasingly essential for emerging sectors, such as electric vehicles, renewable energy, and precision robotics. These industries demand highly precise, reliable, and customized components, positioning investment casting as a key manufacturing technology for future innovations.

Conclusion

Investment casting remains a superior manufacturing solution for achieving exacting tolerances, precision, and complex geometries. Companies seeking competitive advantages through accuracy, reduced production costs, and enhanced product quality should actively embrace investment casting to advance their manufacturing capabilities and meet growing industry demands.

FAQs:

What is investment casting, and why is it preferred for precision manufacturing?

How precise can investment casting tolerances be?

What industries commonly use investment casting for precision components?

What are the main challenges in achieving tight tolerances with investment casting?

How are advances in technology improving precision in investment casting?