Precision Engineering with CNC Machined Parts in Critical Applications

Introduction

CNC machining is a highly precise manufacturing process utilizing computerized controls to operate machine tools. This advanced technology has revolutionized precision engineering, enabling the production of intricate parts with exceptional accuracy, consistency, and efficiency. CNC machining's critical role is especially pronounced in industries requiring precise specifications, where even minor deviations can lead to significant performance failures or safety risks.

1. Aerospace and Defense

The aerospace and defense industries demand stringent standards and precision that CNC machining consistently meets.

Production of complex structural components

CNC machining efficiently creates complex, lightweight structural parts essential for aircraft performance. Components such as wing spars, fuselage sections, and landing gear parts must adhere to precise tolerances, achievable through advanced multi-axis machining processes, to ensure safety and durability.

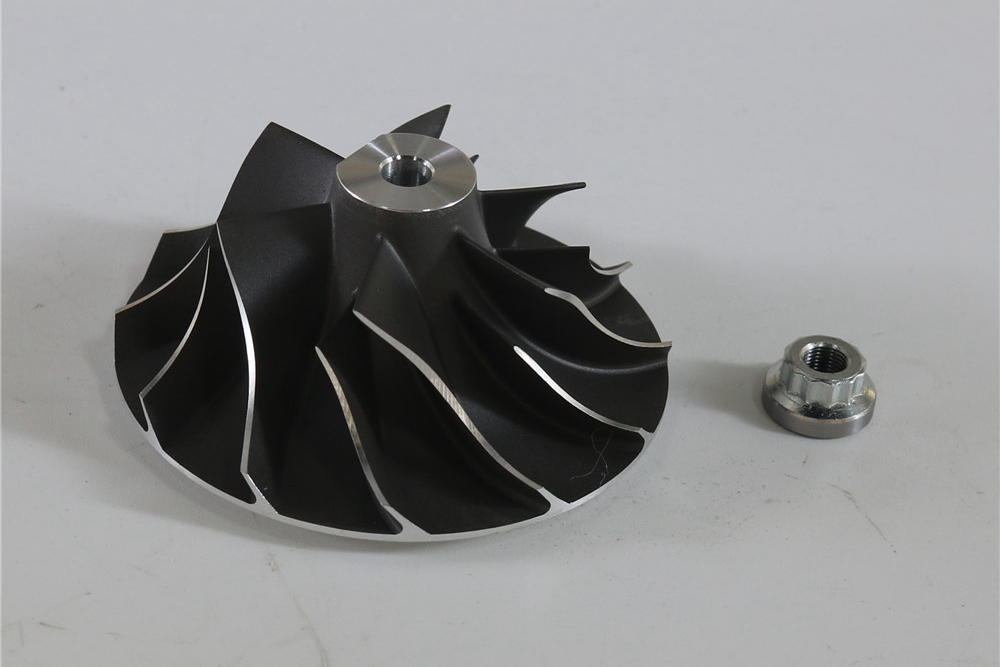

Precision engine components

Engine parts like turbine blades, compressors, and fuel injectors require exceptional precision to withstand extreme operational conditions. CNC machining accurately manufactures these parts from durable materials, including nickel-based superalloys like Inconel 625, crucial for optimal performance and safety.

Reliability in defense applications

Defense applications frequently involve precision CNC machined parts for weapons systems, armored vehicles, and surveillance equipment. CNC ensures reliability and repeatability, critical for defense operations, especially when combined with surface treatments like powder coating for enhanced durability.

2. Medical and Healthcare

CNC machining is pivotal in healthcare by providing precise, hygienic, and reliable components.

Surgical instruments and equipment

Surgical tools like scalpels, forceps, and retractors require precision for accurate performance. CNC machining ensures these instruments meet strict dimensional requirements, employing corrosion-resistant materials such as stainless steel 316L, enhancing patient safety and surgical outcomes.

High-precision implants and prosthetics

Implants such as joint replacements, screws, and plates must perfectly match patient anatomy. CNC machining customizes these components using biocompatible materials like titanium alloys (Ti-6Al-4V), ensuring precise fit, compatibility, and durability.

Customized medical device components

Medical devices such as diagnostic imaging machines and ventilators rely on precision-machined components for operational integrity and accuracy. CNC machining offers tailored solutions, including high-quality plastic injection molded parts, guaranteeing component consistency and reliability.

3. Automotive Industry

The automotive industry leverages CNC machining for its superior precision and efficiency, critical for vehicle performance and safety.

Engine and transmission parts

Precision-engineered parts like pistons, cylinders, and transmission components require strict tolerances for performance and efficiency. CNC machining consistently delivers these parts, often enhanced with treatments such as heat treatment, ensuring exact specifications and minimal waste.

Precision components for electric vehicles

Electric vehicles (EVs) utilize precisely machined components such as battery housings, electric motor casings, and connectors. CNC machining ensures critical tolerances vital for EV efficiency, thermal management, and safety, frequently using high-performance alloys like aluminum die-cast alloys (A380).

High-performance racing components

In motorsports, CNC machining produces high-strength, lightweight components such as suspension, aerodynamic, and engine components. These are often crafted from durable cast titanium alloys, directly impacting vehicle handling, performance, and safety.

4. Electronics and Semiconductor Manufacturing

Precision in electronics manufacturing is crucial due to components' minute scale and complexity.

Precision housings and casings

Electronics casings require meticulous machining for proper assembly, heat dissipation, and environmental protection. CNC machining delivers high-quality, precise casings, often employing anodized aluminum surfaces for improved thermal management and aesthetics.

Microcomponents and connectors

Micro-scale components such as connectors, pins, and leads necessitate extremely tight tolerances. CNC machining produces these miniature parts accurately, leveraging ceramic injection molding techniques, enabling reliable device performance.

Critical tolerances in semiconductor equipment

CNC machining fabricates precision components for semiconductor equipment, such as wafer handling systems and lithography machines, where microscopic deviations can cause operational failures. Materials such as silicon carbide ensure accuracy and durability.

5. Energy Sector

The energy sector relies on CNC machining to produce durable, precise components essential for energy generation and transmission.

High-precision components for turbines

Turbine components, including blades, rotors, and housings, require precise dimensions and exceptional durability. CNC machining guarantees precision, frequently using advanced materials like Haynes 188 alloy to achieve reliable performance.

CNC-machined parts in nuclear reactors

Precision in nuclear reactors is vital for safety and efficiency. CNC machining produces critical reactor parts, often employing surface treatments such as thermal barrier coatings, ensuring exacting standards for operational integrity.

Components for renewable energy systems

Renewable energy systems, such as wind turbines and solar tracking systems, depend on CNC-machined components for precision alignment and structural integrity. CNC machining uses robust materials like carbon steel investment castings, ensuring long-term performance in harsh conditions.

6. Robotics and Automation

CNC machining is indispensable in robotics and automation, producing precise, reliable components that enable consistent and accurate performance.

Precise robotic components

Robotic arms, joints, and sensors require CNC machined parts with exceptional accuracy, frequently utilizing materials like ABS-PC plastics for enhanced durability.

Reliable parts for automated assembly lines

Automated assembly systems depend on accurately machined components such as conveyors, fixtures, and tooling. CNC machining ensures the necessary precision, leveraging sheet metal fabrication processes for high-volume production.

Custom parts for automation systems

Automation often requires custom parts tailored to specific applications. CNC machining efficiently meets these specialized requirements, ensuring precise specifications to enhance system efficiency and performance.

FAQs:

What tolerances can CNC machining achieve?

Which materials are best suited for CNC machining in critical applications?

How does CNC machining ensure part consistency and repeatability?

What are common CNC machining methods used for precision parts?

Why is CNC machining preferred over traditional machining methods for critical applications?