Plastic Injection Mold Life, Materials, and Cost for Manufacturers

Overview of Plastic Injection Molding and Molds

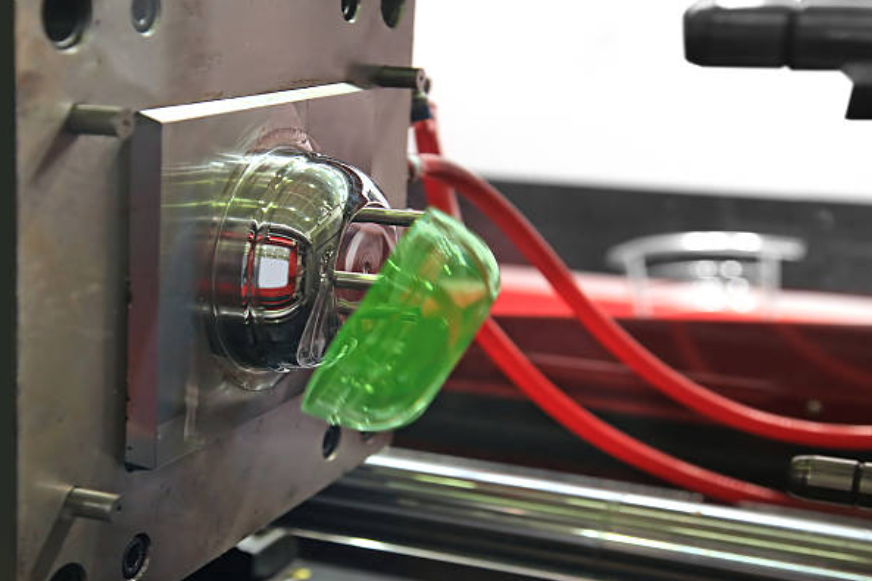

Plastic injection molding is a highly versatile manufacturing process used to produce a wide range of plastic injection mouldings. It involves injecting molten injection molding plastics into a mold cavity, where it cools and solidifies to take the shape of the mold. The injection molding process is widely used in various industries, including automotive, consumer goods, electronics, medical, and packaging.

The mold is a crucial component in plastic injection forming. It is a custom-designed tool that determines the final shape and features of the injection molded parts. The mold consists of two halves, the "core" and the "cavity," which fit together to form the desired part geometry. The core and cavity are typically made of high-strength, heat-resistant materials, such as steel or aluminum, to withstand the molding process's temperature and pressure.

Injection Molding Mold Components and Functions

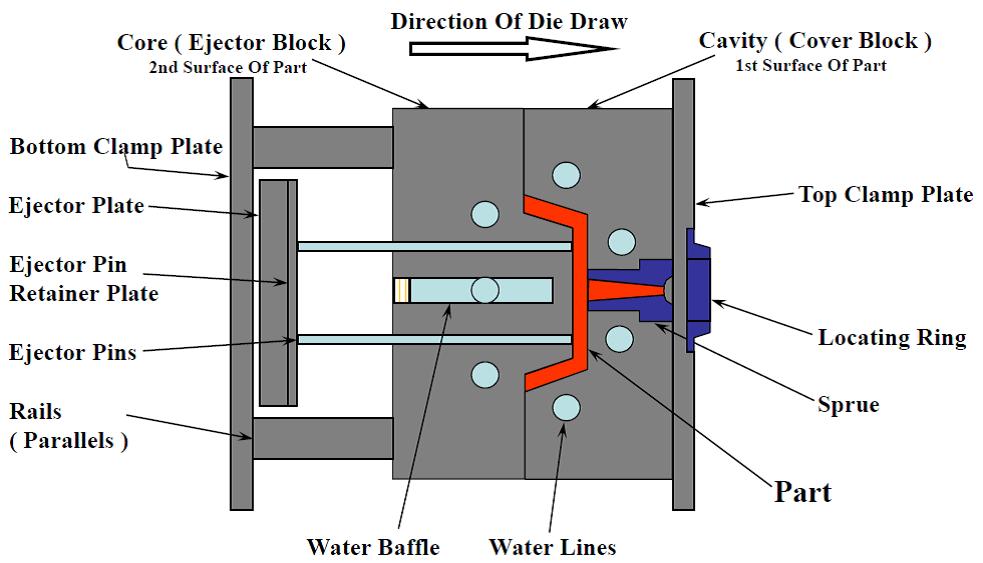

Injection molding molds consist of various components, each serving a specific function in the injected molded plastic part production process. Let's explore the key components of an injection molding mold and their functions:

Cavity and Core

Although the types of injection moulding are not the same. But the mold always consists of two halves, the cavity and core, which fit together to create the mold cavity. The cavity defines the outer surface of the part, while the core shapes the inner surface. These components are usually made of hardened steel or other durable materials to withstand the high pressures and temperatures involved in the molding process.

Runner System

The runner system channels the molten plastic from the injection unit of the molding machine into the mold cavity. It typically consists of a sprue, which connects the machine nozzle to the mold, and a network of channels that distribute the plastic to the various cavities. The design of the runner system affects factors such as flow rate, pressure, and material distribution.

Mold Gate

The gate is the entry point through which the molten plastic enters the mold cavity from the runner system. It controls the flow and direction of the material. Common gate types include sprue gate, edge gate, pin gate, and hot runner systems. The gate size and location are crucial for achieving proper filling of the cavity and minimizing defects.

Cooling System

The cooling system is a network of channels or passages within the mold that facilitate the removal of heat from the molten plastic, allowing it to solidify and cool. Efficient cooling is essential for achieving dimensional stability, reducing cycle time, and preventing part warping. Cooling channels are strategically placed near the cavity walls and core to ensure uniform cooling throughout the part.

Ejector System

The ejector system is responsible for pushing the solidified part out of the mold once it has cooled and hardened. It typically consists of ejector pins or plates, which move into the mold to push the part from the cavity. Proper ejection mechanisms are essential to avoid part damage or deformation during the ejection process.

Venting

Venting is the process of allowing air or gases to escape from the mold cavity during injection. It prevents air traps and ensures that the cavity is adequately filled with molten plastic. Venting can be achieved through small channels or vents strategically placed in the mold to release air without affecting the part's quality.

Guide Pins and Bushings

These components provide alignment and support for the two halves of the mold. Guide pins ensure proper alignment and prevent misalignment during mold closure, while bushings help guide the movement of the mold halves.

Lifters

Lifters are used to create undercuts or features that cannot be formed by a straight-pull mold design. These components help remove the part from the mold by providing additional movement or slides to release the undercut features.

These are the primary components of an injection molding mold and their respective functions. Each component plays a critical role in the overall molding process, ensuring the production of high-quality plastic parts with accurate dimensions, surface finish, and structural integrity.

Types of Plastic Injection Molds and Uses

There are several types of plastic injection molds, each designed for specific applications and part geometries. Let's explore some common types of molds and their uses:

Two-Plate Mold

This is the most basic and commonly used type of injection mold. It consists of two plates, the cavity plate, and the core plate, which are mounted on the mold base. The two-plate mold is suitable for simple part geometries without any undercuts. It allows for easy ejection of the part and is cost-effective for mass production.

Three-Plate Mold

The three-plate mold includes an additional plate called the runner plate or the runner system plate. This plate separates the runner system and the sprue from the molded part. Three-plate molds are used when a separate runner system needs to be ejected along with the part, or when there are complex part designs with multiple gates and runners.

Hot Runner Mold

In a hot runner mold, the runner system and gate are kept at an elevated temperature using heating elements. This eliminates the need for solidified runners to be ejected, reducing material wastage and cycle time. Hot runner molds are commonly used for high-volume production and for parts requiring superior surface finish and dimensional accuracy.

Insert Mold

An insert mold is used when an additional component or insert needs to be incorporated into the molded part during the molding process. Also called insert molding. The insert is placed in the mold cavity before injection, and molten plastic encapsulates the insert, creating a single integrated part. Insert molds are widely used for adding threaded inserts, metal pins, or electrical components to plastic parts.

Overmold

Overmolding involves molding one material over another, creating a multi-material or multi-color part. It is often used to add soft-touch surfaces, ergonomic grips, or decorative elements to a rigid plastic part. Overmolding molds have multiple cavities or sections to accommodate the different materials or colors.

Unscrewing Mold

Unscrewing molds are used for molding parts with threaded features or complex internal threads. These molds have a rotating mechanism that unscrews the molded part from the core as the mold opens, allowing for easy ejection without damaging the threads. Unscrewing molds are commonly used in the production of caps, closures, and containers.

Stack Mold

Stack molds enable simultaneous molding of multiple part cavities in a single mold. They have alternating stack plates that allow for double-sided molding. Stack molds significantly increase production output, as they can produce two or more parts in each molding cycle. They are often used for high-volume production of small, thin-walled parts.

Family Mold

Family molds are designed to produce multiple different parts simultaneously. They consist of multiple cavities, each producing a different part. Family molds are cost-effective for producing a range of parts that share similar characteristics or are used together in an assembly.

10 Factors Affecting Plastic Injection Mold Life

These are some of the common types of plastic injection molds and their respective uses. The selection of the mold type depends on factors such as part complexity, desired features, production volume, and cost considerations. Each mold type offers specific advantages and limitations, and choosing the right mold is crucial for achieving efficient and cost-effective plastic part production.

The lifespan of a plastic injection mold is influenced by several factors that can impact its durability and overall performance. Here are the key factors affecting the mold life:

1. Material Selection: The choice of mold material plays a vital role in determining the mold's longevity. High-quality and durable materials, such as hardened tool steels (e.g., H13, P20, S136), offer better resistance to wear, heat, and corrosion, thereby extending the mold's life.

2. Mold Design: A well-thought-out and robust mold design is crucial for long mold life. Proper consideration of factors such as wall thickness, draft angles, cooling channels, and ejection mechanism helps reduce stress and wear on the mold components, enhancing its longevity.

3. Part and Mold Material Compatibility: Compatibility between the plastic part material and the mold material is essential. Some plastic materials may contain abrasive additives or corrosive elements that can accelerate mold wear. Ensuring that the mold material is compatible with the plastic resin being used is important for maintaining mold integrity.

4. Mold Maintenance: Regular and proper maintenance is critical for extending mold life. Scheduled cleaning, lubrication, and inspection of the mold components help prevent a build-up of contaminants, reduce friction, and detect any potential issues early on, reducing the risk of mold failure.

5. Injection Molding Process Parameters: Optimizing the injection molding process parameters, such as injection speed, pressure, and cooling time, can significantly impact mold life. Properly adjusted parameters ensure efficient plastic filling, cooling, and ejection, minimizing stress on the mold components.

6. Injection Material Quality: Using high-quality plastic resins with consistent properties helps prevent variations that could cause stress on the mold during the molding process. Poor material quality or inconsistent batches can lead to defects and premature mold failure.

7. Mold Venting: Proper mold venting is essential to prevent trapped air or gas during the injection process. Adequate venting reduces the risk of air traps, burn marks, and excessive pressure on the mold, contributing to mold longevity.

8. Part Ejection: The ejection system must be designed and operated correctly to prevent excessive force on the mold when removing the part. Improper ejection can cause damage to the mold and reduce its lifespan.

9. Production Volume: The number of parts produced and the production cycle frequency can affect mold life. High-volume production may lead to accelerated wear and tear on the mold, requiring more frequent maintenance.

10. Environmental Factors: The operating environment, including temperature and humidity, can influence mold performance. Extreme conditions might cause thermal stress and corrosion, affecting the mold's life span.

Regular monitoring of these factors and proactive maintenance practices can help maximize the life of a plastic injection mold, ensuring cost-effective and efficient production over an extended period.

Commonly Used Plastic Injection Mold Materials

According to different injection molding needs, we should choose the appropriate mold. In the injection mold, the mold materials we usually choose include mold steel, hard alloy steel, stainless steel, aluminum alloy, and injection mold plastic. The following are common die steels:

Plastic Injection Mold Material | |||

CH | 2CR13 | 3CR13 | 4CR13 |

(47~52HRC) | (53HRC) | (≥50HRC) | |

H13 | P20 | ||

(47~49HRC) | (27~32HRC) | ||

JAP | NAK80 | NAK55 | SKD61 |

(37~43HRC) | (45HRC) | (40-45HRC) | |

S-STAR | G-STAR | FDAC | |

(30~34HRC) | (35~48HRC) | (40~44HRC) | |

DHA1 | DAC | HPM1 | |

(37~41HRC) | (50~52HRC) | (37~42HRC) | |

HPM2 | HPM50 | HPM38 | |

(29-33HRC) | (37-41HRC) | (50-55HRC) | |

CENA1 | HPM7 | SUS420J2 | |

(40HRC) | (29-33HRC) | (48-55HRC) | |

HPM-MAGIC | DAC-MAGIC | ||

(60-62HRC) | (41-45HRC) | ||

ASSAB | S136 | S136H | 8402 |

(48-54HRC) | (48-54HRC) | (46-53HRC) | |

8407 | NIMAX | 618 | |

(45-52HRC) | (36-40HRC) | (28-33HRC) | |

618HH | 718 | 718HH | |

(36-40HRC) | (33-34HRC) | (36-52HRC) | |

UNIMAX | |||

(56-58HRC) | |||

GER | 2311 | 2312 | 2738 |

(30-36HRC) | (28-33HRC) | (29-33HRC) | |

2738HH | 2316 | 2085 | |

(35-39HRC) | (28-32HRC) | (28-33HRC) | |

2344 | 2343 | 2083 | |

(48-52HRC) | (30-53HRC) | (21-24HRC) | |

How to Choose the Right Plastic Injection Mold Materials?

When selecting the appropriate plastic injection mold material for specific applications, several factors should be considered. These include the type of plastic resin, part complexity, production volume, expected tool life, cost considerations, and environmental factors. Here's a general guide to help you choose the right mold material for common plastic injection applications:

General-Purpose Applications

For general-purpose applications involving commonly used thermoplastics like polypropylene (PP), polystyrene (PS), or polyethylene (PE), materials like P20 or 420 stainless steel are often suitable. These materials offer a good balance of hardness, toughness, and cost-effectiveness for moderate production volumes.

High-Performance Applications

When molding engineering plastics such as ABS, PC, or nylon, higher-performance mold materials like H13 tool steel or beryllium copper can be considered. These materials provide better heat resistance, wear resistance, and dimensional stability to withstand the higher temperatures and stresses associated with engineering resins.

Corrosive Environments

If the plastic resin being molded is corrosive, such as PVC (polyvinyl chloride) or filled resins, corrosion-resistant mold materials like stainless steel (e.g., 420 or 440) or beryllium copper are recommended. These materials offer excellent resistance to corrosion and prevent premature mold failure.

High-Volume Production

For high-volume production, where the mold is subjected to prolonged use and faster cycle times, materials with high wear resistance and thermal conductivity, such as H13 tool steel, can be advantageous. H13 is known for its ability to withstand high production volumes and is commonly used in demanding applications like automotive or consumer goods.

Thin-Wall Molding

When molding thin-wall parts, materials with good thermal conductivity are beneficial to achieve rapid heat transfer and efficient cooling. Aluminum molds are often preferred due to their lightweight nature and excellent thermal conductivity, which enables faster cycle times and improved part quality.

High-precision and Optical Applications

For applications that require an exceptional surface finish, optical clarity, or high precision, mold materials with superior polishability, such as stainless steel or nickel-plated tool steels, are recommended. These materials help achieve the desired surface aesthetics and minimize defects in applications like lenses, light guides, or consumer electronics.

It is important to consult with experienced mold manufacturers or material suppliers who can provide specific recommendations based on the unique requirements of your application. They can help identify the most suitable mold material that balances performance, cost, and tool life for your specific plastic injection molding needs.

9 Factors Influencing Mold Production Cost

Several factors influence the production cost of plastic injection molds. Understanding these factors can help in estimating and optimizing the cost of mold production. Here are the key factors that influence mold production cost:

1. Part Complexity: The complexity of the part design directly affects the mold production cost. Parts with intricate features, undercuts, thin walls, or complex geometries require more sophisticated mold designs and manufacturing processes, leading to higher costs.

2. Mold Size and Cavities: The physical size of the mold and the number of cavities required for producing multiple parts in each molding cycle impact the mold production cost. Larger molds and molds with higher cavity counts require more material, machining, and assembly time, resulting in increased costs.

3. Mold Material: The choice of mold material affects both the initial cost and the durability of the mold. High-quality mold materials, such as tool steels, are more expensive upfront but offer better longevity and performance. The selection of the mold material depends on factors like part complexity, expected tool life, and cost considerations.

4. Mold Complexity and Features: The complexity of the mold design and the presence of additional features, such as slides, lifters, or inserts, contribute to the overall mold production cost. These additional features require more intricate machining, assembly, and often involve more complex mold actions, increasing the cost.

5. Tolerance and Surface Finish Requirements: Tighter tolerances and higher surface finish requirements demand more precise machining and polishing processes. Achieving strict tolerances and superior surface finish increases the cost of mold production due to the need for specialized equipment and skilled labor.

6. Mold Lifespan and Durability: Longer mold lifespan and enhanced durability often require the use of higher-quality materials, advanced surface treatments, and better mold construction techniques. While this increases the initial cost of the mold, it can result in lower long-term production costs due to reduced mold maintenance and replacement expenses.

7. Production Volume: The desired production volume influences the mold production cost. For high-volume production, more durable molds with optimized cooling and ejection systems may be required, leading to higher upfront costs but lower per-part costs in the long run. Conversely, for low-volume production or prototyping, less expensive mold options like aluminum may be more cost-effective.

8. Lead Time and Urgency: The desired lead time and urgency of the mold production can impact the cost. Tighter timelines may require expedited manufacturing processes, increased labor allocation, or prioritized material sourcing, leading to additional costs.

9. Additional Services and Post-Production Requirements: Additional services such as mold testing, sampling, and modification, as well as post-production services like part inspection, packaging, and shipping, can add to the overall mold production cost.

It is important to consider these factors and collaborate with experienced mold manufacturers or suppliers to optimize the mold design and production process to balance cost, quality, and efficiency. A thorough understanding of the project requirements and effective communication with the mold manufacturer can help in achieving the desired balance and cost optimization.

9 Strategies for Mold Cost Optimization

1. Design for Manufacturability: Collaboration between part design engineers and mold manufacturers early in the design process is essential. Designing parts with moldability in mind, considering factors like draft angles, wall thickness, and eliminating unnecessary features or undercuts, can simplify the mold design and reduce manufacturing complexities and costs.

2. Material Selection: Choosing the appropriate mold material based on the expected production volume and part requirements is important. Opt for cost-effective mold materials that meet the desired performance criteria. Balancing the material cost with the expected tool life and maintenance requirements can help optimize mold cost.

3. Simplify Mold Design: Keeping the mold design as simple as possible without compromising functionality is key to cost optimization. Minimize the number of mold components, eliminate unnecessary features, and simplify the ejection and cooling systems. A simpler mold design reduces manufacturing complexities, machining time, and assembly costs.

4. Standardize Components: Standardizing mold components, such as ejector pins, guide pins, and leader pins, can significantly reduce costs. Standard components are readily available, less expensive, and can be easily replaced if needed. This approach also simplifies maintenance and repair processes.

5. Optimize Cavitation: Determine the appropriate number of cavities based on production volume requirements. Increasing the number of cavities can increase production efficiency and reduce the per-part cost. However, it is important to balance the cavitation with part quality, cycle time, and machine capacity.

6. Efficient Cooling System Design: Proper cooling is crucial for cycle time optimization. Optimize the cooling system design by incorporating conformal cooling channels, ensuring uniform cooling and shorter cycle times. Efficient cooling reduces energy consumption, improves part quality, and increases productivity.

7. Tooling and Manufacturing Process Selection: Choose the most appropriate tooling and manufacturing processes based on the production volume and part complexity. For low-volume production or prototyping, processes like 3D printing or soft tooling may be more cost-effective. High-volume production may benefit from more durable tooling options like hardened steel molds.

8. Mold Maintenance and Preventive Measures: Regular mold maintenance and proactive preventive measures help prolong tool life and reduce unexpected downtime and repair costs. Implementing a maintenance schedule, cleaning the mold after each production run, and promptly addressing issues can prevent costly breakdowns and extend the lifespan of the mold.

9. Supplier Collaboration and Competitive Bidding: Engage with multiple mold suppliers and obtain competitive bids to ensure you are getting the best value for your investment. Collaborate closely with the selected mold supplier to discuss cost-saving opportunities, alternative design options, and manufacturing efficiencies.

Neway Mold Assurance and Guarantee

In 30 years of manufacturing experience, we have learned that it is extremely important to produce according to the needs of our customers. Neway can customize the mold life according to project requirements. For example, if you only need to produce 1000 mold times, Neway can customize the injection mold with a mold life of about 1000 mold times. Minimize initial cost. At the same time, for mass-produced products, Neway can guarantee free maintenance for life.

Please contact us if you have a project on hand that needs to be evaluated.