Metal Injection Molding (MIM) Vs. Investment Casting

Metal Injection Molding (MIM) and Investment Casting are two distinct manufacturing processes used to create metal parts, each with advantages and limitations.

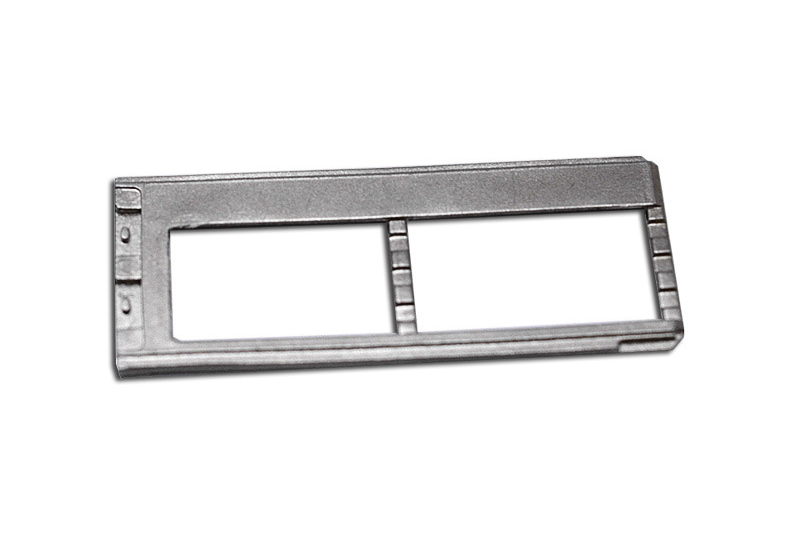

Metal Injection Molding Process

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the durability and properties of metal materials. Fine metal powders are mixed with a binding agent to create a feedstock, which is then injected into molds to form intricate and precise metal parts. After molding, the parts go through debinding and sintering processes to remove the binder and fuse the metal particles, resulting in high-quality, near-net-shape metal components with excellent mechanical properties.

MIM is valued for its ability to produce complex geometries and is widely used in various industries, including automotive, aerospace, healthcare, and electronics. The MIM process is mainly used for manufacturing small and complex parts.

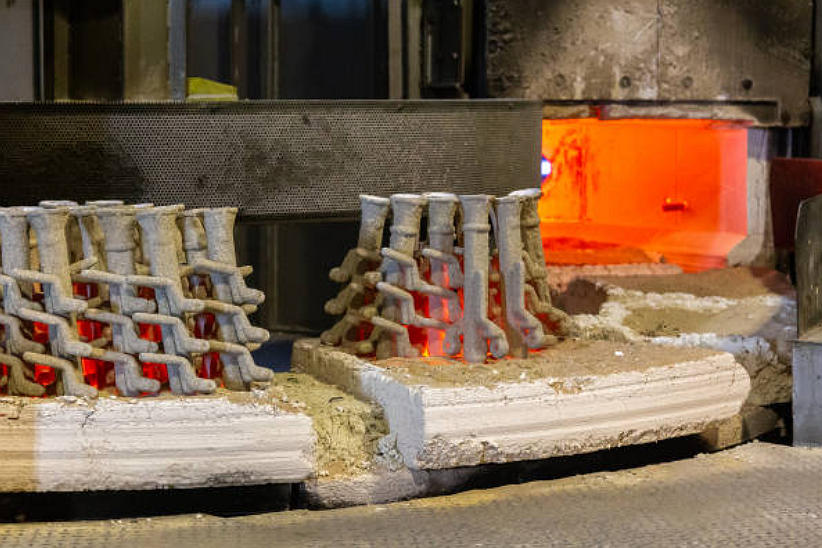

Investment Casting Process

Investment casting, also known as precision casting or lost wax casting, is a manufacturing process where a wax or resin pattern is coated with a ceramic shell. This shell is then heated to remove the wax, leaving behind a cavity. Once the shell is removed, molten metal is poured into the cavity, creating intricate and precise metal parts.

Investment casting is favored for its ability to produce highly detailed and complex components, often with excellent surface finishes, making it a choice for aerospace, automotive, and art industries. The investment casting process is mainly used for small-medium and complex parts manufacturing.

Material Comparision

MIM supports various materials, including hard metals, magnetic alloys, and high melt point metals, like Cobalt Alloys and tungsten Alloys.

Investment casting is primarily used for metals and alloys with lower melting points, limiting material options, such as Copper Alloys, Aluminum Alloys, and Stainless Steel.

Metal Injection Molding Materials | Investment Casting Materials |

Complexity And Tolerance

MIM excels in producing highly complex and intricate parts with fine details. It allows for producing parts with features such as undercuts, thin walls, and complex geometries that are difficult to achieve using other manufacturing methods. MIM can achieve tight tolerances, often between ±0.05 mm (±0.002 inches) or even tighter, making it suitable for high-precision components.

Investment casting is also capable of producing complex shapes with excellent surface finish. It is well-suited for parts with intricate details, curved surfaces, and thin sections. Investment casting can achieve tight tolerances, typically within ±0.5 mm (±0.02 inches), although achieving extremely tight tolerances may require additional machining.

In terms of complexity and tolerances, the MIM process is superior. Both processes can realize products of higher complexity, but MIM parts are more precise.

Cost and Production Volume

Material Costs:

Metal Injection Molding uses fine metal powders mixed with a binder. The cost of metal powders can be relatively high, depending on the material selected. For example, MIM stainless steel powders are about 10 USD/Kg. However, the amount of stainless steel used in investment casting is about 3 USD/Kg. Investment casting typically uses bulk materials, and the cost is generally lower than MIM.

Tooling Costs:

MIM requires expensive tooling, including injection and shaping molds, which can significantly impact the initial setup costs. Although MIM's initial mold cost is higher, its mold life is longer, as low as 50K shots. For mass-produced parts, it is more of an excellent deal.

The initial mold cost of investment casting is relatively lower than that of MIM, especially for more superficial and smaller components. At this point, investment casting is more cost-effective in low to medium-volume production.

Labor Costs:

MIM involves multiple stages, including mixing, injection molding, debinding, and sintering. This complexity can lead to higher labor costs. However, MIM manufacturers can equip automated or semi-automated MIM parts production lines to cut labor costs. The steps of investment casting are relatively simple and mainly rely on manual operation. Operators with rich experience can improve the yield and reduce the cost to a certain extent. It can be seen that MIM is more suitable for the production of medium and large quantities of parts, while investment casting is suitable for small and medium quantity production.

Investment casting is cost-effective for low to medium-volume production and can handle moderately complex geometries. It may be preferred for applications where tooling costs need to be minimized and precision is not as critical as in MIM.

Neway, as a production engineer, can assess the specific requirements of each project and recommend the most cost-effective manufacturing method based on factors like production volume, component complexity, and budget constraints, ensuring that the chosen process aligns with the project's goals.

Surface Finish

Surface Finish in Metal Injection Molding (MIM):

Smoothness: MIM can achieve a relatively smooth surface finish. However, the final surface quality depends on factors such as the quality of the molds, debinding, and sintering conditions. MIM parts may have a slightly textured appearance due to the powder particles.

Precision: MIM offers high precision and can accurately reproduce intricate details and delicate features. Typically, Neway can produce MIM parts with an accuracy of +/-0.02mm or above.

Post-Processing: In some cases, MIM parts may require post-processing, such as polishing or machining, to achieve a smoother surface or improve dimensional accuracy. It can add to the cost and lead time.

Surface Finish in Investment Casting:

Smoothness: Investment casting typically produces parts with a smoother surface finish than MIM. The process involves creating a wax pattern with a high-quality surface, which is then used to create the mold.

Precision: Investment casting can achieve good precision but may not be as inherently precise as MIM for intricate details. Some minor surface imperfections or parting lines can occur, which may require additional finishing.

Post-Processing: Investment casting parts may also require post-processing, such as sanding or machining, to remove any remaining imperfections and achieve the desired surface finish.

Thin-Wall Capabilities

Metal Injection Molding (MIM):

MIM excels at producing components with intricate and thin-wall geometries due to its ability to replicate fine details in molds.

MIM can achieve wall thicknesses as low as 0.4 millimeters (0.02 inches) or even thinner in some cases, making it ideal for miniaturized and complex parts.

The process allows for high precision in replicating thin-wall features, resulting in excellent dimensional accuracy. Despite its ability to create thin walls, MIM can be sensitive to variations in wall thickness. Thinner walls may require careful process optimization to control shrinkage and ensure the final part's integrity.

Investment Casting

Investment casting can also produce components with thin walls, although it is generally more suitable for moderately thin walls than MIM.

As low as 1.5 millimeters (0.06 inches), wall thicknesses can be achieved with investment casting, making it suitable for many applications.

Investment casting may require additional considerations for fragile walls. Achieving uniform thickness and avoiding defects like shrinkage cavities or surface irregularities can be more challenging.

Complex thin-wall geometries may require extra attention during the casting and cooling to prevent issues.

More FAQs

Investment Castings:

1. What is the Difference Between Sand and Investment casting

2. What is Investment Casting Process?

3. Can Titanium be Investment Casted?

Metal Injection Molding:

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?