Metal Injection Molding Materials | MIM-420 Stainless Steel

Overview of MIM-420 Stainless Steel

MIM-420 Stainless Steel is a martensitic grade material known for its high strength, hardness, and wear resistance combined with moderate corrosion resistance. This blog post aims to provide a comprehensive overview of MIM-420 Stainless Steel, its key features, mechanical and physical properties, and its role in various industries, particularly in metal injection molding.

What is MIM-420 Stainless Steel

MIM-420 Stainless Steel is a martensitic grade material that is a combination of high strength, hardness, and wear resistance with moderate corrosion resistance. This material is magnetic and typically has less distortion with vacuum heat treatment over oil quenching.

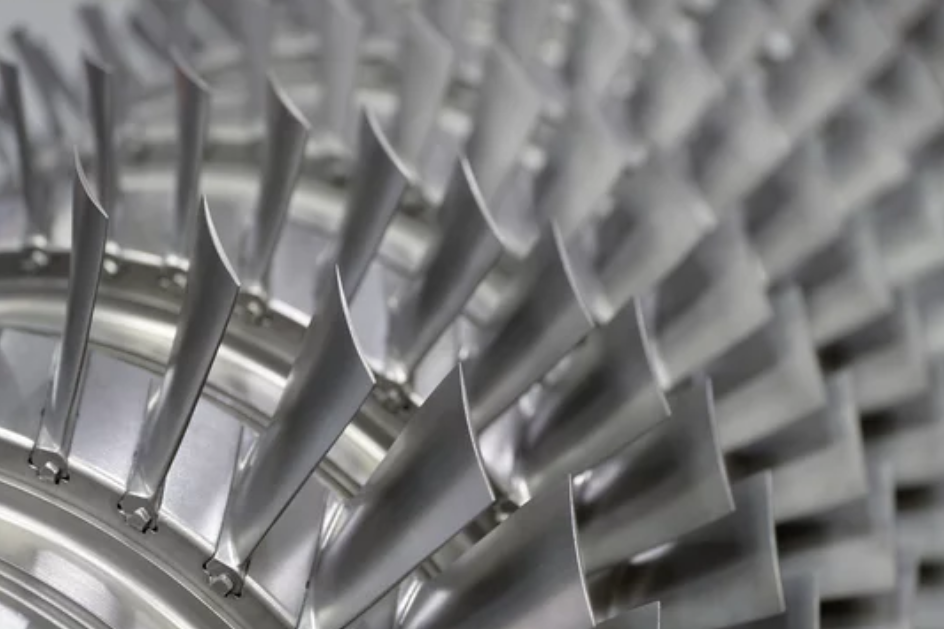

It has found its place in various industries due to its unique properties. It is often used for aerospace, automotive, cutlery, defense, power hand tools, and surgical instruments.

Key Features of MIM-420 Stainless Steel

Here are some of the key features of 420 stainless steel processed through metal injection molding (MIM):

- High hardness - Can be heat treated to achieve hardness in the range of 52-57 HRC. Significantly harder than austenitic grades like 316L.

- Excellent wear resistance - The high hardness imparts excellent abrasion and wear resistance. Makes it suitable for dynamic components subject to wear.

- Good corrosion resistance - The 12-14% chromium content provides moderate corrosion resistance, better than carbon steels but less than 300 series stainless.

- Attractive cost - More affordable than tool steel MIM. Allows replacing machined tool steels with near-net shape MIM 420 parts.

- Dimensional stability - Low thermal expansion and high temper resistance allows good dimensional control.

- Complex geometries - Intricate shapes and features can be molded to near-net shapes. Minimizes machining.

- Fine microstructure - Rapid cooling from MIM produces very fine martensitic grains and carbides compared to wrought 420.

- Customizable properties - Hardness, strength, and toughness can be tailored through heat treatment.

Overall, 420 MIM combines the shape complexity and cost benefits of MIM with the hardness, wear resistance, and corrosion resistance of 420 stainless steel. An excellent material solution for small, durable parts and tooling.

Mechanical Properties of MIM-420 Stainless Steel

MIM-420 Stainless Steel exhibits impressive mechanical properties that make it suitable for various applications. Here are some of the typical mechanical properties:

Property | Value |

|---|---|

Carbon (C) | 0.16~0.25 |

Manganese (Mn) | ≤1.00 |

Silicon (Si) | ≤1.00 |

Chromium (Cr) | 12.0~14.0 |

Nickel (Ni) | ≤0.75 |

Phosphorus (P) | ≤0.04 |

Sulfur (S) | ≤0.03 |

Tensile Strength (σb, MPa) | ≥635 (Quenched and tempered) |

Yield Strength (σ0.2, MPa) | ≥440 (Quenched and tempered) |

Elongation (δ5, %) | ≥20 (Quenched and tempered) |

Impact Energy (Akv, J) | ≥63 (Quenched and tempered) |

Hardness (HB) | ≤223 (Annealed); ≥192 (Quenched and tempered) |

These properties make MIM-420 Stainless Steel suitable for applications requiring high strength and excellent wear resistance.

Physical Properties of MIM-420 Stainless Steel

The physical properties of MIM-420 Stainless Steel contribute to its unique characteristics and wide range of applications. Here's a table showing its composition:

Property | Value |

Tensile Strength (σb, MPa) | ≥635 (Quenched and tempered) |

Yield Strength (σ0.2, MPa) | ≥440 (Quenched and tempered) |

Elongation (δ5, %) | ≥20 (Quenched and tempered) |

Impact Energy (Akv, J) | ≥63 (Quenched and tempered) |

Hardness | ≤223HB (Annealed); ≥192HB (Quenched and tempered) |

Chemical Composition of MIM-420 Stainless Steel

Element | Composition |

Carbon (C) | 0.16~0.25 |

Manganese (Mn) | ≤1.00 |

Silicon (Si) | ≤1.00 |

Chromium (Cr) | 12.0~14.0 |

Nickel (Ni) | ≤0.75 |

Phosphorus (P) | ≤0.04 |

Sulfur (S) | ≤0.03 |

Applications of MIM-420 Stainless Steel

MIM-420 Stainless Steel finds its applications in various industries due to its unique combination of high strength, hardness, wear resistance, and moderate corrosion resistance. Some of the key industries where MIM-420 Stainless Steel is used include:

Cutlery and Knives: The high hardness (52-57 HRC) allows knives and blades to take and retain a sharp cutting edge. Corrosion resistance is also vital for cutlery.

Medical Instruments: The hardness provides good wear resistance for surgical tools like scalpels and orthopedic instruments. Corrosion resistance is vital for biocompatibility.

Valves and Fluid System Components: 420 stainless has excellent abrasion and erosion resistance needed for valves and components handling fluids, especially at high velocities. Hardness resists wear.

Plastic Injection Molds: The hardness provides outstanding durability against abrasive wear from glass or mineral-filled plastics flowing over mold surfaces during injection molding.

Mechanical Parts: Bushings, ball bearings, and other mechanical parts gain hardness, wear resistance, and moderate corrosion resistance for reliable performance.

Tooling and Gauges: 420 can replace tool steels for taps, reamers, and other tooling needing good temper resistance and hardness at lower costs.

MIM-420 Application in Power Tools

MIM-420 stainless steel is commonly used in the following applications owing to its unique combination of properties:

Cutlery and Knives: The high hardness (52-57 HRC) allows knives and blades to take and retain a sharp cutting edge. Corrosion resistance is also vital for cutlery.

Medical Instruments: The hardness provides good wear resistance for surgical tools like scalpels and orthopedic instruments. Corrosion resistance is vital for biocompatibility.

Valves and Fluid System Components: 420 stainless has excellent abrasion and erosion resistance needed for valves and components handling fluids, especially at high velocities. Hardness resists wear.

Plastic Injection Molds: The hardness provides outstanding durability against abrasive wear from glass or mineral-filled plastics flowing over mold surfaces during injection molding.

Mechanical Parts: Bushings, ball bearings, and other mechanical parts gain hardness, wear resistance, and moderate corrosion resistance for reliable performance.

Tooling and Gauges: 420 can replace tool steels for taps, reamers, and other tooling needing good temper resistance and hardness at lower costs.

Power Tools Parts Case Study

MIM-420 stainless steel has some valuable properties that make it suitable for application in power tools:

- High hardness and wear resistance - Power tools undergo significant wear and abrasion on internal components from high-speed metal-on-metal contact. The hardness 420 (52-57 HRC) resists this abrasive wear.

- Good toughness - Power tools experience high-impact loads. 420 provides better fracture toughness than other stainless steels to withstand intermittent shocks.

- Moderate corrosion resistance - Power tools work in non-ideal environments exposed to moisture and oils. 420 provides better rust resistance than carbon steel.

- High temper resistance - Many power tool components must maintain dimensional stability at elevated operating temperatures. 420 resists softening up to about 300°C.

- Complex geometries - MIM processing allows complex internal component shapes needed in modern power tool assemblies.

- Cost efficiency - 420 MIM provides an economical alternative to machined tool steel components in power tools.

Specific applications include gear shafts, spindle bearings, and impacting and gripping components that require hardness, wear, heat resistance, and geometric flexibility. MIM-420 meets the challenging property requirements for durable power tool parts.

Conclusion

MIM-420 Stainless Steel is a martensitic grade material known for its high strength, hardness, and wear resistance, combined with moderate corrosion resistance. These properties make it a preferred choice for various applications, particularly in metal injection molding.

Whether you're a part designer or a purchaser with procurement needs for MIM parts, understanding the properties and applications of MIM-420 Stainless Steel can help you make informed decisions. Its unique combination of properties makes it a valuable material in various industries, including aerospace, automotive, cutlery, defense, power hand tools, and surgical instruments.

In the case of power tools, the high strength, hardness, and wear resistance of MIM-420 Stainless Steel make it an excellent choice for components that need to withstand high levels of stress and wear. Furthermore, its low distortion with vacuum heat treatment ensures that these components maintain their shape and dimensions, ensuring their performance and longevity.

More MIM Materials

Stainless Steel | ||

MIM 304l | Excellent corrosion resistance. High strength and hardness after heat treatment. | Biocompatible grades are used in medical applications. Widely used for small complex parts needing corrosion resistance. |

MIM 440C | ||

MIM 430 | ||

MIM 316 | ||

Low Alloy Steels | ||

MIM 4605 | Achieve very high tensile and yield strengths after heat treatment. Good toughness and ductility in heat-treated conditions. | Used for high-strength structural components. |

MIM 4140 | ||

MIM 4340 | ||

MIM 2700 (FN08) | ||

MIM 2200 (Fe-2Ni) | ||

MIM 52100 | ||

MIM 8620 | ||

MIM 9310 | ||

MIM 430L | ||

Tool Steel | ||

MIM H13 | Excellent hardness, wear, and abrasion resistance.Dimensional stability and strength maintained at high temperatures | Used for small precision tooling components like inserts and dies |

MIM P20 | ||

MIM S7 | ||

MIM M2 | ||

MIM D2 | ||

Magnetic | ||

Fe-Ni Alloy | Tailored magnetic properties like high permeability and low core losses | Used in electronics components like inductors, relays, sensors |

Fe-Si Alloy | ||

Fe-Co Alloy | ||

Copper Alloys | ||

Copper | Good corrosion resistance, electrical and thermal conductivity, Anti-friction performance | Used for electrical connectors, heat exchangers, fittings, bearings |

Bronze | ||

Brass | ||

Tungsten and Copper alloy | ||

Titanium Alloys | ||

Ti-6Al-4V (Grade 5) | High strength-to-weight ratio. Good high-temperature properties | Used widely in aerospace and medical implants |

Heavy Alloys | ||

Wu-Ni-Fe | Extremely high density, hardness | Used as counterweights, vibration-dampening weights |