Material Versatility: Expanding Product Potential with Diverse Rapid Molding Options

Rapid molding has become essential in modern manufacturing, facilitating accelerated production times, cost savings, and remarkable flexibility. Central to rapid molding is the extensive selection of materials manufacturers can employ, ranging from versatile engineering plastics to robust high-performance alloys. The ability to choose from various materials significantly expands the potential of product designs, allowing businesses to respond rapidly to market demands and streamline product development cycles.

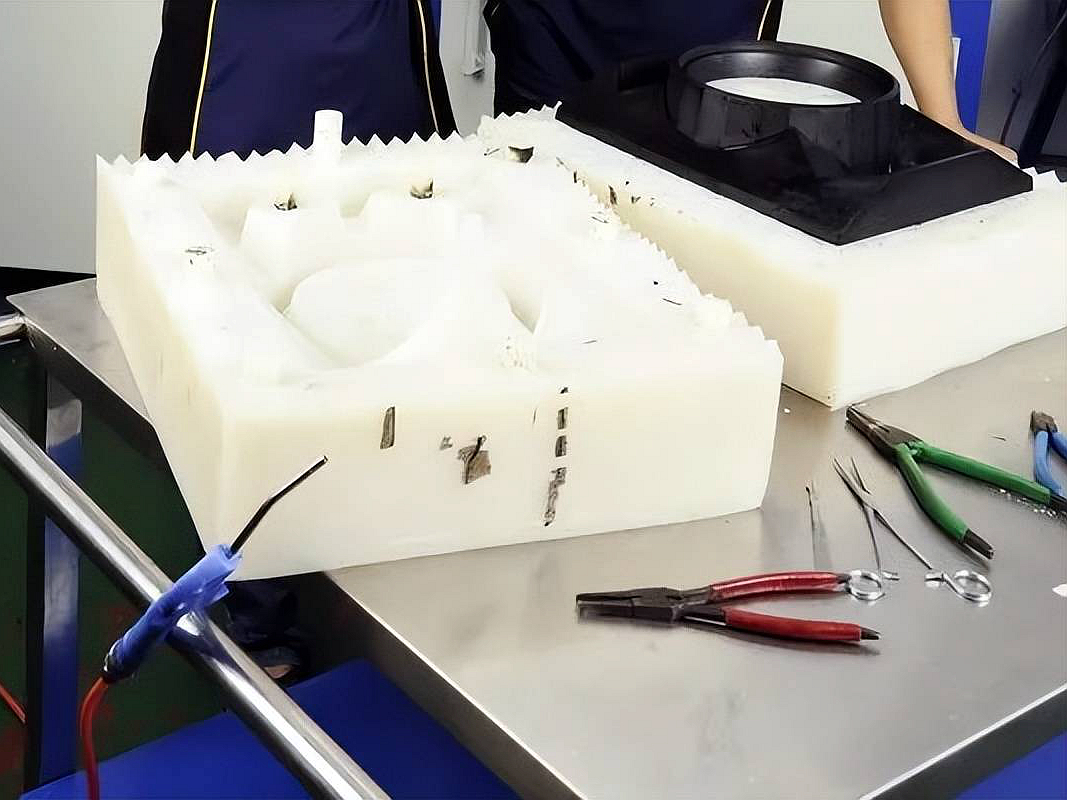

Understanding Rapid Molding

Rapid molding refers to advanced manufacturing processes that swiftly create components through plastic injection molding, casting, and thermoforming methods. The key advantage of rapid molding lies in its ability to produce complex components efficiently, reducing lead times compared to traditional approaches like conventional metal casting. This rapid production capability is invaluable for prototyping, small-batch manufacturing, and automotive, healthcare, aerospace, and consumer electronics industries.

Key benefits of rapid molding include:

Shorter lead times from concept to finished product

Lower tooling expenses

Ability to quickly iterate and refine prototypes

Ideal for custom orders and limited-volume production

Exploring Material Choices in Rapid Molding

The effectiveness of rapid molding largely depends on the choice of materials, each offering distinct advantages for specific applications:

Thermoplastics

Common thermoplastics used include ABS, Nylon (PA), Polycarbonate (PC), and Polypropylene (PP), renowned for their adaptability, mechanical strength, and cost-efficiency. These materials can be reshaped and recycled repeatedly, making them sustainable options ideal for rapid prototyping and mass production.

Thermosets

Thermosetting polymers, including epoxy resins and silicone rubbers, provide dimensional stability and high-performance characteristics. Unlike thermoplastics, thermosets permanently solidify after curing, making them perfect for durable, demanding industrial applications.

Metals

Rapid molding increasingly integrates metallic materials such as aluminum, zinc-based, stainless steel, and high-performance alloys like Inconel. These metals provide superior strength, thermal conductivity, and corrosion resistance, suitable for challenging industrial environments.

Ceramics

Advanced ceramic materials like Alumina, Zirconia, and Silicon Nitride (Si₃N₄) offer exceptional heat resistance, hardness, and durability. Ceramics are particularly valuable for applications requiring high precision and wear and thermal stress resistance.

Material Properties and Their Applications

Material selection significantly impacts the mechanical performance and functional characteristics of the final product:

Thermoplastics: Easily molded with excellent strength-to-weight ratios, frequently utilized in automotive components, household products, and protective casings for electronics.

Thermosets: Provide superior heat and chemical resistance, making them ideal for durable components, electrical housings, and industrial equipment requiring prolonged operational reliability.

Metals: Offer exceptional structural strength, corrosion resistance, and thermal performance, commonly utilized in automotive components, aerospace applications, and precision-engineered medical devices.

Ceramics: Widely employed in high-temperature environments, ceramics excel in applications such as wear-resistant components, medical implants, and aerospace parts requiring exceptional durability and dimensional accuracy.

Matching Materials to Product Requirements

Selecting appropriate materials is critical for rapid molding success. Manufacturers must carefully evaluate key factors, including structural requirements, thermal performance, weight constraints, visual appeal, and budget considerations.

For instance, automotive components demanding lightweight yet durable characteristics may favor thermoplastics such as reinforced nylon, whereas high-temperature aerospace components benefit from metal injection molded superalloys. Such strategic decisions directly influence product durability, performance, and commercial success.

Innovations in Rapid Molding Materials

Continuous innovation expands the boundaries of rapid molding materials, driving new applications and improved performance:

Recent developments include:

Bioplastics: Environmentally-friendly alternatives derived from renewable resources are increasingly prevalent, supporting manufacturers’ sustainability goals while maintaining performance standards.

Advanced Metal Alloys: New alloys, such as titanium grades, offer higher strength-to-weight ratios and improved corrosion resistance, significantly broadening rapid molding capabilities for aerospace and medical sectors.

Hybrid Ceramic Composites: Innovations in ceramic materials, including alumina-zirconia blends, provide exceptional mechanical and thermal properties, ideal for demanding industrial and medical applications.

Continuous technological advancements further diversify rapid molding material options, enhancing product capabilities and expanding potential applications.

Recent innovations include:

Bioplastics: Renewable, eco-friendly polymers are increasingly chosen for their sustainability, aligning with evolving environmental standards and reducing manufacturers' ecological footprint.

Advanced Ceramics: Innovative formulations of materials such as silicon carbide significantly increase product durability in demanding operational conditions.

Nano-Enhanced Polymers: Incorporating nanomaterials enhances mechanical strength, durability, and conductivity, pushing rapid molding materials into applications previously dominated by traditional manufacturing methods.

Sustainability Considerations

Given the growing emphasis on sustainability, manufacturers increasingly favor environmentally friendly materials for rapid molding:

Recyclable thermoplastics significantly reduce waste streams.

Sustainable material choices like bioplastics and biodegradable polymers help companies meet stringent ecological regulations and market demands for greener products.

Manufacturers also adopt low-impact finishing processes, such as powder coating, to enhance aesthetics and durability without compromising environmental responsibility.

Innovations in Rapid Molding Materials

Continuous innovation expands the capabilities and potential applications of rapid molding materials:

Recent advancements include:

High-performance thermoplastics offer improved heat and chemical resistance.

Metal injection molding (MIM) innovations allow complex geometries in metals like stainless steel, enhancing design flexibility and reducing production costs.

Ceramic injection molding advancements increase dimensional precision, enabling applications in precision engineering and high-performance industrial environments.

Such material innovations continuously expand the possibilities of rapid molding, allowing manufacturers to simultaneously elevate product performance and sustainability.

Sustainability Considerations

Choosing sustainable materials has become crucial for manufacturers seeking ecological responsibility:

Employing recyclable thermoplastics or biodegradable materials reduces environmental impact and promotes responsible production.

Opting for efficient, low-waste processes like rapid molding helps businesses align with modern sustainability expectations and achieve compliance with environmental regulations.

Conclusion

Material versatility is central to unlocking rapid molding’s full potential. Manufacturers can drive innovation, accelerate product development, and effectively respond to evolving market demands by strategically selecting materials based on performance, functionality, and sustainability criteria. As rapid molding technologies and materials advance, manufacturers will continue to benefit from expanded possibilities and superior market competitiveness.