Key Industrial Applications of Aluminum Die Castings in Manufacturing

Introduction

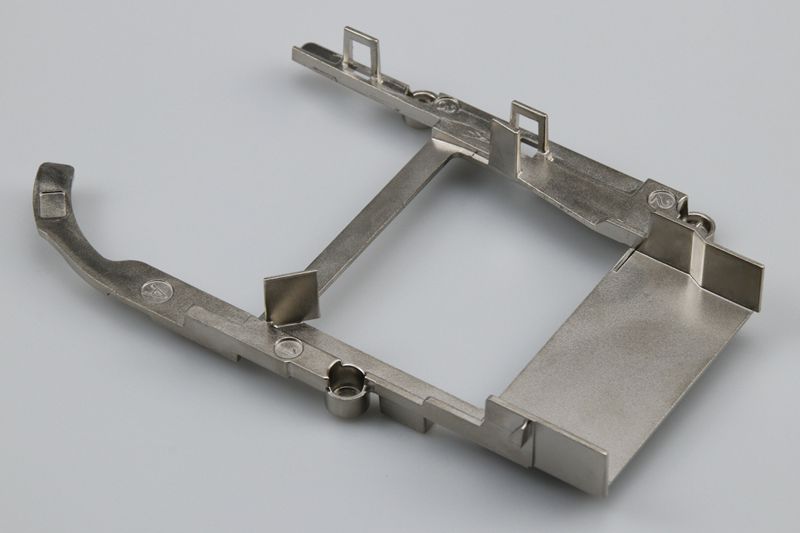

Aluminum die casting is an advanced manufacturing technique that injects molten aluminum alloys into precision molds under high pressure. Renowned for efficiently producing intricate and robust components, aluminum die casting has become indispensable across various industries, including automotive, aerospace, electronics, and construction. Its versatility and cost-effectiveness make it a strategic manufacturing solution essential in today's highly competitive industrial landscape.

Understanding Aluminum Die Casting

The aluminum die-casting process involves injecting molten aluminum into steel molds—called dies—at high pressures. This technique enables rapid manufacturing of complex parts with exceptional precision, consistency, and repeatability. Since molds are reusable, aluminum die casting is particularly effective for high-volume production, offering considerable cost-efficiency.

Commonly utilized aluminum alloys include A380, known for versatility and mechanical strength; ADC12, preferred in automotive and electronics sectors due to superior castability; and A383, recognized for excellent corrosion resistance. Aluminum inherently offers lightweight characteristics, high strength-to-weight ratios, superb thermal conductivity, and dimensional accuracy, essential for demanding industrial applications.

Benefits of Using Aluminum Die Castings

Industries choose aluminum die castings due to numerous inherent advantages:

Lightweight with High Strength-to-Weight Ratio: Aluminum die casting creates strong yet lightweight components, critical in industries like automotive and aerospace for optimizing performance and fuel efficiency.

Excellent Thermal and Electrical Conductivity: Ideal for heat dissipation components and electronic enclosures, ensuring consistent performance even under operational stress.

Superior Corrosion Resistance: Aluminum naturally resists corrosion, significantly enhancing the longevity and reliability of manufactured products exposed to harsh environments.

High Dimensional Accuracy and Surface Finish: The precision of die casting yields intricate components requiring minimal post-processing, effectively reducing production time and costs.

Industrial Applications of Aluminum Die Castings

Automotive Industry

The automotive sector employs aluminum die casting extensively for essential components like engine blocks, cylinder heads, pistons, and transmission housings. Aluminum’s lightweight and excellent heat dissipation properties directly contribute to improved fuel economy, vehicle durability, and reduced emissions. Structural automotive components also utilize aluminum castings for superior strength and safety.

Aerospace and Defense

Aluminum die castings are vital in aerospace and defense applications, where lightweight yet robust parts are essential. The process produces high-strength structural components, avionics housings, and heat-resistant engine parts. Under demanding operational conditions, these components significantly enhance aircraft performance, fuel efficiency, reliability, and safety.

Electronics Industry

Aluminum die casting is critical for electronics, producing durable enclosures, heat sinks, cooling components, and connectors. Aluminum’s exceptional thermal management and dimensional accuracy benefit electronics like computers, telecommunications equipment, and consumer electronics, ensuring prolonged component life, improved performance, and enhanced reliability.

Construction and Industrial Equipment

In construction and industrial equipment, aluminum die casting produces robust fittings, brackets, and machinery housings. Components such as pumps, motors, and structural frames exhibit enhanced durability, resistance to environmental factors, and reliability under heavy workloads. This contributes significantly to longer equipment lifecycles, minimized maintenance, and overall operational efficiency.

Consumer Goods

Consumer goods widely integrate aluminum die castings in products like appliances, power tools, and outdoor gear. Appliance housings, handheld power tool bodies, and sporting equipment components benefit from aluminum’s strength and lightweight attributes, offering consumers durable products that consistently perform, boosting brand reputation and user satisfaction.

Case Studies and Practical Examples

Real-world industry applications illustrate aluminum die casting’s practical advantages:

Automotive Transmission Housing: Automotive manufacturers utilizing aluminum die casting achieve lighter transmission housings, significantly improving vehicle fuel efficiency, thermal performance, and structural durability.

Electronics Heat Sinks: Aluminum die-cast heat sinks used in computer processors effectively manage heat, boosting processing capabilities and component longevity.

Aircraft Avionics Housing: Aluminum die-cast avionics housings protect sensitive aerospace electronics against extreme environmental conditions, demonstrating superior reliability, lightweight performance, and long-term durability.

Future Trends in Aluminum Die Casting

As manufacturing evolves, aluminum die casting is advancing in several notable directions:

Advanced Alloy Development: Continuous research in aluminum alloys aims to improve mechanical properties, corrosion resistance, and thermal conductivity, tailoring solutions for increasingly demanding applications.

Sustainable Manufacturing Practices: Sustainability drives innovations such as recycling aluminum scrap, employing energy-efficient casting techniques, and adopting biodegradable release agents, significantly lowering environmental impact.

Digital Manufacturing and Automation Integration: Leveraging Industry 4.0, aluminum die casting processes now integrate automation, robotics, and digital quality monitoring systems. These advancements provide greater precision, shorter cycle times, and improved data-driven production control.

Conclusion

Aluminum die casting remains a cornerstone technology in modern manufacturing, offering unmatched advantages in strength, precision, lightweight construction, and corrosion resistance. From automotive and aerospace to electronics and consumer goods, diverse industries continue to benefit significantly from this process. Looking forward, alloy innovations, sustainability, and automation ensure aluminum die casting will play an increasingly crucial role in shaping manufacturing’s future capabilities and competitive landscape.

FAQs

What makes aluminum ideal for die casting?

What industries commonly use aluminum die castings?

How does aluminum die casting enhance product durability?

Are aluminum die castings cost-effective for mass production?

What are common aluminum alloys used in die casting?