Insert Molding | Process, Considerations, and Applications

Insert molding is a highly versatile and efficient manufacturing process that has revolutionized the production of custom parts in various industries. By seamlessly combining plastic and other materials, insert molding provides enhanced functionality, durability, and design flexibility. In this comprehensive guide, we will delve into the intricacies of insert molding, exploring its process, applications, benefits, and considerations. Whether you're a part design engineer or a buyer in search of custom insert molding solutions, this guide will equip you with the knowledge necessary to make informed decisions.

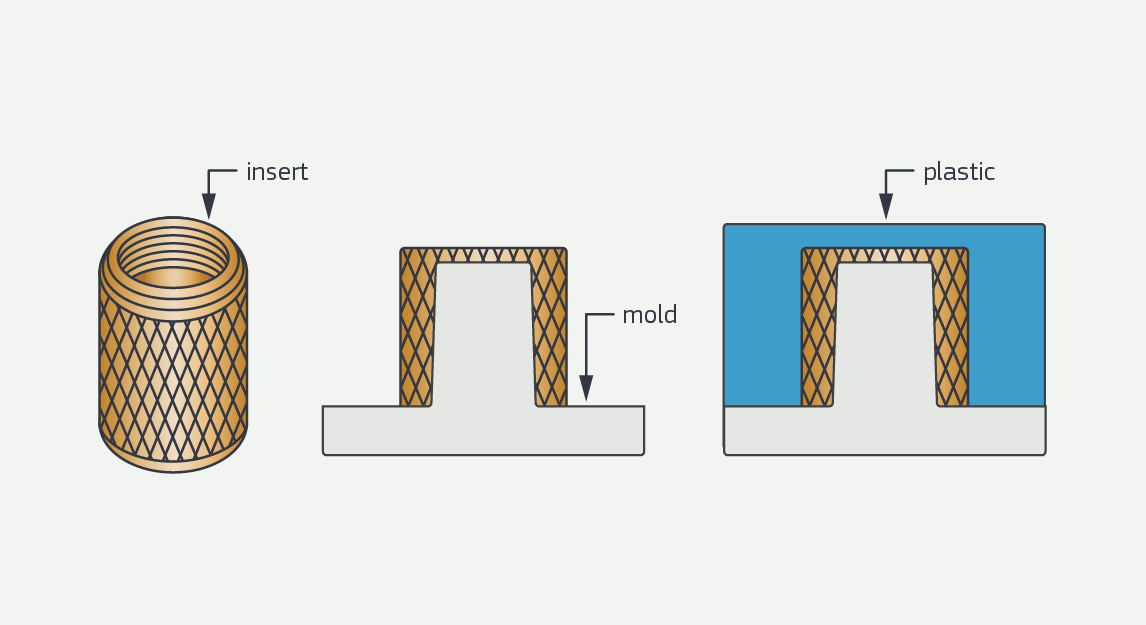

Definition and Overview of Insert Molding

Insert molding, also known as insert moulding, is a specialized plastic injection molding technique that involves encapsulating pre-formed inserts or components within a plastic part. This process offers numerous advantages, including improved part strength, reduced assembly time, and enhanced design possibilities. By combining multiple materials into a single integrated component, insert molding eliminates the need for additional assembly steps, resulting in a more efficient and cost-effective manufacturing process.

Process of Insert Molding

To fully grasp the benefits of insert molding, it's crucial to understand the process itself. Insert molding typically involves the following steps:

Insert Preparation

Plastic injection molding inserts, which can be made of metal, plastic, or other materials, are carefully selected and prepared for the molding process. These inserts can take various forms, such as threaded inserts, electrical connectors, or reinforcement plates.

Mold Preparation

An injection mold is created with cavities that correspond to the desired shape and dimensions of the final part. The mold also includes channels and gates through which the molten plastic will flow. This is an injection mold with insert positioning, which includes the placement position of inserts and the injected plastic space to wrap inserts

Inserts Placement

The prepared inserts are precisely positioned within the mold cavities. The inserts may be manually placed or loaded using automated equipment, depending on the complexity of the final parts.

Injection Molding

Once the inserts are in place, the injection mold is closed, and the plastic material is injected into the mold under high pressure. The molten plastic surrounds the inserts, bonding with them during the cooling and solidification process.

Cooling and Ejection

The mold is cooled to allow the plastic to solidify and take the desired shape. Once cooled, the mold opens, and the finished part, fused with the inserts, is ejected.

Step-by-Step Guide to Insert Molding

Design Considerations for Insert Molding Parts

Several factors must be considered when designing parts for insert molding to ensure successful outcomes. These include:

- Insert Selection

Choosing the appropriate insert material and type is crucial for achieving the desired functionality and performance of the final part. Factors such as strength, conductivity, and compatibility with the plastic material must be evaluated.

- Insert Placement and Orientation

The position and orientation of the inserts within the mold impact the part's strength, assembly ease, and overall quality. Properly aligning the inserts and providing adequate support structures are vital considerations. We can manually place inserts for products with low complexity or low requirements. In most cases, we recommend placing inserts automatically with robotic arms. If you are looking for a reliable insert molding supplier, the automatic and precise placement of inserts can be your selection indicator.

Material Selection and Compatibility

The selection of plastic material for insert molding is another critical aspect. Factors such as mechanical properties, chemical resistance, and temperature requirements must be considered. It's essential to choose a plastic material that bonds well with the inserts and provides the necessary strength and durability for the intended application. If you don't know how to choose inserts and plastic materials, consult Neway's insert molding engineer.

Cost and Efficiency Factors to Consider

Insert molding offers significant cost savings and efficiency improvements compared to traditional assembly methods. By eliminating secondary operations, reducing labor costs, and streamlining production, insert molding can result in a more cost-effective manufacturing process. However, it's important to carefully evaluate the upfront tooling costs, material costs, and overall production volume to determine the economic viability of insert molding for a specific project.

Quality Control and Inspection Methods

Maintaining strict quality control measures throughout the insert molding process is crucial to ensure the production of high-quality parts. Various inspection methods, such as visual inspection, dimensional analysis, and mechanical testing, can be employed to verify the integrity of the inserts, the bond strength between the plastic and inserts, and the overall part quality. Implementing robust quality control protocols helps in delivering parts that meet the required specifications and customer expectations.

Applications of Insert Molding

Insert molding finds extensive applications across a wide range of industries thanks to its versatility and numerous benefits. Let's explore some of the key industries and specific applications where insert molding excels:

Automotive Industry Applications

The automotive industry extensively uses insert molding to enhance various components' performance, safety, and aesthetics. Examples of insert molded parts in automobiles include:

Electrical connectors

Insert molding allows for the integration of electrical connectors directly into components, ensuring reliable electrical connections and reducing assembly complexity.

Overmolded handles and grips

By molding soft-touch materials onto handles and grips, insert molding provides enhanced ergonomics and comfort for the driver and passengers.

Threaded inserts for fasteners

Insert molded threaded inserts provide secure and durable attachment points for fasteners, eliminating the need for separate nut and bolt assemblies.

Electronics and Electrical Applications

In the electronics and electrical industries, insert molding plays a crucial role in producing complex and reliable components. Some examples include:

Encapsulated PCBs

Insert molding enables the encapsulation of printed circuit boards (PCBs), protecting them from environmental factors, moisture, and vibration.

Sensor housings

Sensors used in various applications, such as temperature, pressure, and proximity sensing, can be encapsulated with insert molding, ensuring their protection and precise placement.

Connectors and terminals

Insert molding allows for connecting connectors and terminals directly into plastic housings, ensuring secure and efficient electrical connections.

Medical and Healthcare Applications

In the medical and healthcare fields, insert molding offers numerous advantages in terms of stability, biocompatibility, and functionality. Some applications include:

Medical device components

Insert molding is commonly used to produce components such as catheters, syringes, connectors, and surgical instruments, where precision, reliability, and cleanliness are paramount.

Drug delivery systems

Insert molding enables the integration of drug delivery mechanisms into devices, such as inhalers and insulin pens, ensuring accurate dosing and ease of use.

Implantable devices

Insert molding is utilized to manufacture implantable devices, such as pacemaker components and orthopedic implants, where combining different materials and precise dimensions is critical.

Consumer Products and Appliances Applications

In the consumer products and appliances sector, insert molding offers design flexibility, improved aesthetics, and enhanced functionality. Examples include:

Handles and grips

Insert molding allows for the integration of comfortable and ergonomic handles and grips for products such as power tools, kitchen appliances, and personal care devices.

Buttons and switches

Insert molding enables the production of durable and aesthetically pleasing buttons and switches for electronic devices, household appliances, and automotive controls.

Enclosures and housings

Insert molding is commonly employed to create protective and functional enclosures and housings for various consumer products, including audio devices, cameras, and home automation systems.

Industrial and Manufacturing Applications

In industrial and manufacturing settings, insert molding provides significant advantages in terms of strength, durability, and assembly efficiency. Some applications include:

Industrial equipment components

Insert molding is used to produce components for heavy-duty machinery, such as gears, pulleys, and connectors, where robustness and dimensional accuracy are essential.

Tool handles and grips

Insert molding allows for the creation of comfortable and slip-resistant handles and grips for hand tools, improving worker productivity and safety.

Customized parts for manufacturing processes

Insert molding enables the production of customized parts, such as fixtures, jigs, and clamps, that are tailored to specific manufacturing processes, improving efficiency and accuracy.

Benefits of Custom Insert Molding

Custom insert molding offers a range of advantages over traditional manufacturing methods. Let's explore some of the key benefits:

Improved Product Performance and Reliability

By integrating inserts directly into plastic parts, insert molding enhances the overall performance and reliability of the components. The strong bond between the plastic and inserts ensures secure attachment, minimizing the risk of component failure or detachment during use. This leads to improved product performance, longevity, and customer satisfaction.

Enhanced Design Flexibility and Customization Options

Insert molding opens up a world of design possibilities, allowing for complex shapes, intricate features, and multi-material combinations. Designers can incorporate inserts with different functions, such as threaded inserts, electrical contacts, or reinforcement elements, into a single molded part. This versatility enables the creation of unique and innovative products that meet specific application requirements.

Cost Savings and Reduced Assembly Time

One of the significant advantages of insert molding is the elimination of separate assembly steps. Manufacturers can reduce labor costs and assembly time by integrating inserts during the molding process. The streamlined production process also minimizes the risk of assembly errors, improving efficiency and cost savings. Additionally, consolidating multiple parts into a single molded component can lead to overall cost reduction.

Increased Part Strength and Durability

Insert molding enhances plastic parts' strength and durability by reinforcing them with inserts. The inserts act as load-bearing structures, strengthening critical areas and reducing the likelihood of failure under stress or impact. This increased strength allows for the production of lightweight parts without compromising performance, making insert molded components ideal for applications that require both strength and weight reduction.

How to Choose a Reliable Insert Molding Service Provider

When it comes to custom insert molding, selecting a reliable service provider is crucial for the success of your project. Here are some factors to consider when choosing an insert molding partner:

Factors to Consider When Selecting an Insert Molding Partner

Expertise and Experience

Look for a service provider with extensive expertise and experience in insert molding. A company specializing in this process will have the knowledge, skills, and insights to handle your specific project requirements.

Manufacturing Capabilities

Evaluate the manufacturing capabilities of the service provider. Consider factors such as the size and complexity of parts they can handle, the range of materials they work with, and the available equipment and technologies. Ensure that the service provider can meet your production needs.

Design and Engineering Support

A reliable insert molding partner should offer comprehensive design and engineering support. They should be able to assist you in optimizing your part design for insert molding, recommend suitable materials, and provide valuable insights to improve the manufacturability and functionality of your components.

Quality Control Measures

Quality is of utmost importance when it comes to insert molded parts. Inquire about the quality control measures implemented by the service provider. Look for certifications such as ISO 9001, demonstrating their commitment to maintaining high-quality standards. Additionally, ask about their inspection protocols, testing capabilities, and adherence to industry-specific quality requirements.

Evaluating Expertise, Experience, and Capabilities

When assessing potential insert molding service providers, ask for case studies or examples of similar projects they have completed. This will give you an idea of their expertise in your industry and their ability to deliver successful outcomes. Additionally, request references or testimonials from previous clients to gain insights into their reliability, professionalism, and customer satisfaction.

Arrange a meeting or consultation with the service provider to discuss your project requirements in detail. During this interaction, evaluate their communication skills, responsiveness, and willingness to address your concerns or questions. A reliable partner will proactively understand your needs and provide tailored solutions.

Reviewing Customer Testimonials and Case Studies

Customer testimonials and case studies are valuable resources to assess the reputation and track record of an insert molding service provider. Look for reviews or testimonials on their website or reputable industry platforms. Pay attention to feedback regarding the service provider's communication, project management, on-time delivery, and overall customer experience.

Case studies showcasing successful insert molding projects can give you confidence in the service provider's ability to handle complex requirements, meet tight tolerances, and deliver high-quality results. These examples can also provide insights into the industries they serve and the types of applications they specialize in.

Conclusion

In conclusion, insert molding is a versatile and efficient manufacturing process that offers numerous benefits for custom parts production. By seamlessly integrating inserts into plastic components, insert molding enhances performance, provides design flexibility, reduces assembly time, and increases part strength.

With its wide range of applications across industries such as automotive, electronics, medical, consumer products, and manufacturing, insert molding has become an integral part of modern manufacturing processes. The ability to create complex, multi-material components with improved functionality and reliability makes insert molding an attractive option for part design engineers and buyers alike.

When choosing an insert molding service provider, it's essential to consider factors such as expertise, experience, manufacturing capabilities, and quality control measures. By selecting a reliable partner with a proven track record, you can ensure the success of your insert molding projects and achieve high-quality, customized parts that meet your specific requirements.