Industries and Applications Benefiting from Sheet Metal Stamping Techniques

Introduction

Sheet metal fabrication through stamping is an extensively used manufacturing process that forms flat metal sheets into specific shapes using pressing operations. Renowned for precision, efficiency, and versatility, stamping techniques have become essential across various sectors. By streamlining production and delivering consistent quality, sheet metal stamping significantly contributes to modern manufacturing advancements, providing cost-effective solutions for high-volume custom parts manufacturing.

1. Automotive Industry

The automotive sector benefits immensely from advanced stamping processes because they efficiently produce high-quality, safety-critical components in large volumes.

Production of automotive body panels

Sheet metal stamping creates durable, lightweight vehicle components such as door panels, roofs, and hoods, ensuring minimal waste and precise alignment. These precision-formed parts contribute significantly to vehicle aerodynamics, strength, and fuel efficiency.

Manufacture of precision engine components

Critical engine parts, including valve covers, oil pans, and transmission components, depend on precision stamping to ensure consistency, reliability, and adherence to stringent automotive manufacturing standards.

Safety-critical components such as airbag housings

Stamping processes play a pivotal role in creating essential safety components, such as airbag housings, seatbelt mechanisms, and braking systems, demanding stringent quality controls to safeguard passenger safety in e-mobility applications.

2. Aerospace and Aviation

Sheet metal stamping significantly aids aerospace industries by providing precision-engineered, lightweight components critical for performance, reliability, and safety.

Lightweight structural components

Aerospace components such as wings, fuselage sections, and landing gear elements utilize stamping techniques to reduce aircraft weight, thereby enhancing fuel efficiency and overall flight performance.

Precise brackets and fasteners

High-precision stamped brackets and fasteners ensure structural integrity and reliable attachment of critical aviation components, which are essential for safe and efficient flight operations.

Specialized cabin interior components

Interior components like overhead compartments, seating frames, and safety fixtures are regularly stamped for precision, consistency, and durability, significantly enhancing passenger comfort and safety through meticulous fabrication processes.

3. Electronics and Consumer Goods

The electronics sector heavily relies on sheet metal stamping to produce precise, reliable components for devices and home appliances, ensuring performance consistency and durability.

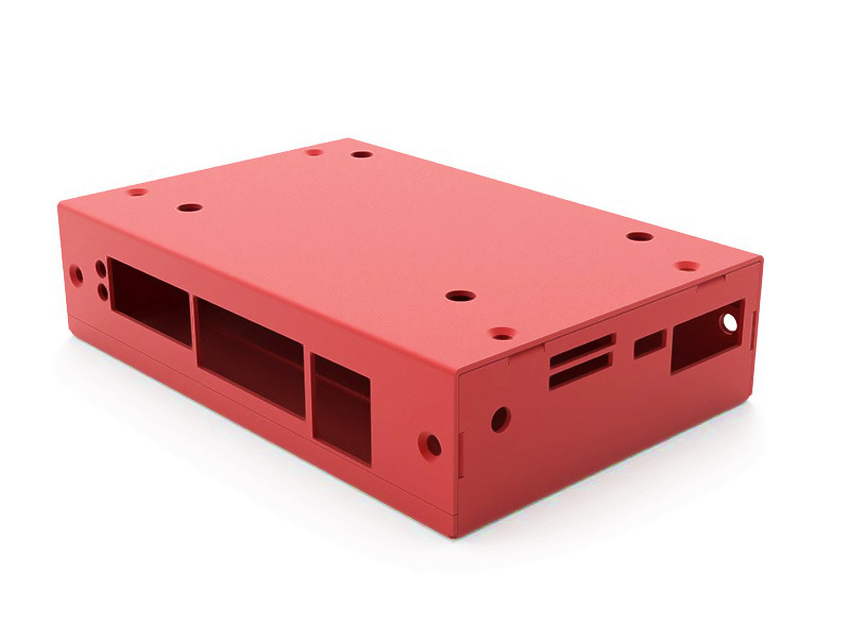

Production of casings for electronics

Metal stamping efficiently creates protective housings and casings for electronics such as computers, smartphones, and audio equipment, providing both aesthetic appeal and robust protection through carefully managed surface treatments.

Detailed components for home appliances

Stamped internal components, such as brackets, heat sinks, and panels for refrigerators and ovens, consistently meet performance requirements due to the high accuracy and reliability inherent in stamping techniques, supplemented by advanced metal finishing methods.

Small connectors and hardware

Small, intricate connectors and precision hardware produced through stamping ensure accuracy, high-volume production capabilities, and cost-effectiveness critical to the consumer electronics industry.

4. Medical Devices

Medical device manufacturing leverages stamping due to the critical need for precision, cleanliness, and structural reliability in healthcare applications.

Surgical instruments and medical tools

Precision stamping consistently produces surgical tools, clamps, and medical instruments, ensuring accuracy, reliability, and adherence to rigorous standards essential for medical devices.

High-precision medical device housings

Complex casings for devices like ventilators and monitors benefit significantly from stamping, offering exact dimensional control and durability essential in clinical environments, often requiring high-quality stainless steel.

Durable implants and instrumentation

Stamped metal components frequently serve as medical implants and orthopedic devices, chosen for their dimensional accuracy, biocompatibility, and reliability essential in surgical procedures.

5. Construction and Infrastructure

Sheet metal stamping techniques offer robust, reliable components essential for structural integrity and efficiency in construction and infrastructure.

HVAC components and ductwork

Stamped HVAC components, including precise ductwork, vents, and fittings, guarantee airtight sealing, ensuring energy-efficient and reliable climate control solutions in buildings.

Structural brackets and support systems

Construction projects rely extensively on stamped brackets, beams, and connectors to provide stability, accurate alignment, and durability, which are essential for structural integrity and building aesthetics.

Building fixtures and fittings

Stamped metal fixtures, lighting housings, and decorative fittings offer both functional strength and aesthetic versatility, greatly enhancing modern architectural designs.

6. Renewable Energy

Renewable energy industries, particularly solar and wind power, increasingly depend on stamping techniques to produce durable, efficient components capable of withstanding environmental stresses.

Solar panel frames and supports

Stamped solar panel frames and support structures provide critical strength, corrosion resistance, and precision alignment, essential for long-lasting solar installations.

Components for wind turbines

Wind turbine components such as nacelle covers and internal brackets benefit from stamping processes, offering exceptional strength, precision, and reliability necessary for demanding renewable energy environments.

Battery storage enclosures

Stamped metal enclosures safeguard battery storage systems, offering robust protection against environmental hazards and ensuring safe and efficient energy storage solutions.

7. Automotive E-Mobility

The rapid growth of electric vehicles has emphasized the need for precise and lightweight stamped components, crucial for enhancing performance, efficiency, and safety in EVs.

Electric motor housings

Stamped electric motor housings deliver precise dimensional control and durability, essential for optimal thermal management, structural integrity, and EV performance.

Battery trays and protective covers

Precision-stamped battery trays and covers are vital for protecting high-voltage battery systems and improving thermal control, safety, and overall electric vehicle reliability.

Structural lightweight solutions

Stamped lightweight parts significantly reduce vehicle weight, extending battery efficiency, vehicle range, and overall energy performance within the e-mobility sector.

Conclusion

Sheet metal stamping techniques remain fundamental to modern manufacturing by providing efficient, precise, and versatile solutions across diverse industries. Its ability to produce high-quality, consistent components at scale ensures continued relevance, driving industrial advancement and innovation.

FAQs:

What materials are typically used in sheet metal stamping?

How precise can sheet metal stamping processes be?

What are the common defects in sheet metal stamping, and how can they be prevented?

How cost-effective is sheet metal stamping compared to other fabrication methods?

What factors influence the choice of materials for sheet metal stamping?