high-precision-cnc-machining-ensuring-accuracy-for-complex-parts

Introduction

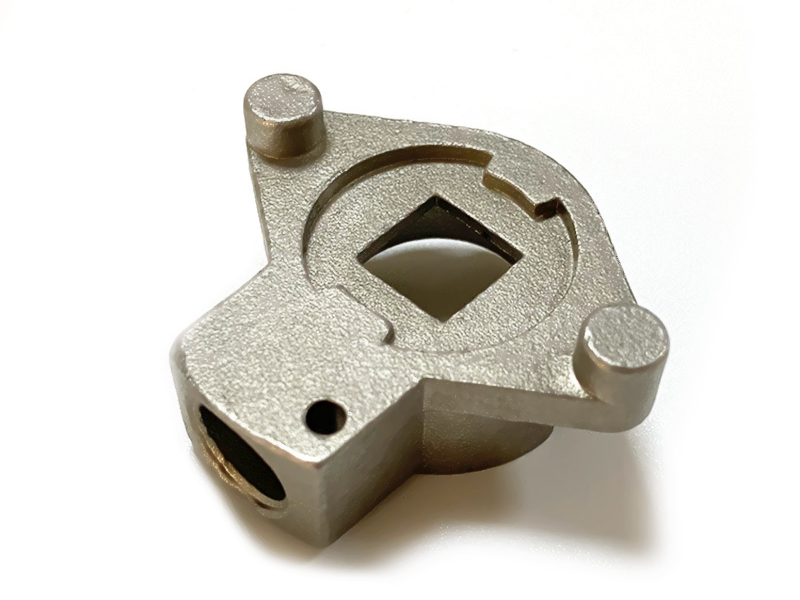

CNC machining is a widely utilized manufacturing process that employs computer-controlled machines to produce precise, repeatable parts and components. The demand for intricate and highly accurate components has increased significantly across various industries such as aerospace, automotive, medical devices, and consumer electronics. High-precision CNC machining is an essential solution for manufacturing these complex parts. This article explores how high-precision CNC machining achieves remarkable accuracy, identifies common challenges, and presents effective solutions to maintain precision.

Understanding High-Precision CNC Machining

High-precision CNC machining refers to a machining process capable of achieving exceptionally tight tolerances, often within microns. It involves advanced machinery and tools operated via precise computer programming, enabling the creation of intricate geometries with repeatable accuracy.

Common applications include:

Aerospace components: turbine blades and structural parts

Medical devices: surgical instruments and implant parts

Automotive parts: high-performance engine components, transmission systems

Electronics: precision housings, connectors, and internal structures

High-precision CNC machining consistently delivers reliability, precision, and quality demanded by critical sectors.

Key Factors Ensuring Accuracy in CNC Machining

Achieving superior accuracy in CNC machining involves various crucial factors:

Material Selection Considerations: Different materials exhibit distinct machining behaviors. Selecting suitable materials, such as high-strength aluminum alloys, stainless steel, titanium alloys, or specialized engineering plastics, directly influences achievable tolerances and surface finish quality.

Machinery Calibration: Regular calibration of CNC machines is essential to maintain consistent performance. Machines must be routinely checked and calibrated to minimize inaccuracies caused by wear, misalignment, or environmental factors, thereby enhancing overall accuracy.

Tool Selection and Maintenance: Precision tools, specifically designed for tight tolerances, are crucial. Regular inspections, timely replacements, and proper storage conditions ensure optimal tool performance and reduce machining errors significantly.

Techniques for Achieving High Precision

To reach exceptional precision, several advanced techniques are employed:

Multi-Axis CNC Machining: Employing multi-axis CNC machining significantly increases flexibility and accuracy, allowing complex geometries to be machined in fewer setups. This reduces cumulative errors and enhances overall precision.

Computer-Aided Manufacturing (CAM) Software: Advanced CAM software facilitates highly detailed programming and simulation of machining operations, ensuring optimal tool paths and minimal material deformation, contributing to superior accuracy and reduced production time.

Real-Time Monitoring and Adjustments: Integrating real-time monitoring systems allows immediate detection of deviations, facilitating on-the-spot adjustments during machining operations to consistently maintain dimensional accuracy.

Common Challenges and Solutions

Despite the high level of precision achievable, CNC machining faces several challenges:

Thermal Deformation and Temperature Control: Temperature fluctuations can result in dimensional inaccuracies. Implementing temperature-controlled machining environments and thermal compensation strategies effectively mitigates these issues, maintaining part integrity.

Tool Wear and Lifespan Management: Tool wear impacts accuracy significantly. Monitoring tool conditions, proactive replacement schedules, and employing high-quality cutting materials help manage and minimize tool wear, thereby maintaining precision throughout production.

Minimizing Vibration and Ensuring Stability: Machine vibration during high-precision machining leads to poor surface finishes and dimensional inaccuracies. Employing rigid setups, proper tool balancing, and optimized machining parameters significantly reduces vibration, enhancing accuracy and surface finish quality.

Quality Assurance Methods

Ensuring the accuracy of CNC machined parts involves stringent quality control measures:

Inspection Methods: Advanced inspection methods such as Coordinate Measuring Machines (CMM) and optical measurement systems precisely measure and verify dimensional accuracy. These sophisticated methods quickly identify deviations, maintaining strict industry quality standards.

Statistical Process Control and Tolerance Verification: Using statistical process control (SPC) techniques ensures machining processes remain stable and within specified tolerances, significantly reducing variability in final components and ensuring reliable performance.

Post-Machining Inspection and Quality Assurance Practices: Comprehensive post-machining inspections ensure adherence to precise specifications, confirming part integrity and compliance with stringent industrial application standards.

Conclusion

High-precision CNC machining offers substantial benefits by ensuring accuracy, repeatability, and superior quality for complex parts. Manufacturers can achieve unmatched precision by proactively addressing common challenges through proper material selection, regular calibration, advanced machining techniques, and robust quality assurance. Partnering with experienced CNC machining providers ensures optimal results, fostering innovation and excellence in critical industries.

Related FAQs:

What factors affect precision in CNC machining?

How accurate is CNC machining?

What materials can be machined with high-precision CNC machining?

How can thermal deformation be minimized during CNC machining?

What are the benefits of using multi-axis CNC machining?