High Accuracy: Achieving Precision in Molded Parts with Rapid Molding

Introduction

Precision is paramount in modern manufacturing, especially as industries demand greater reliability, enhanced performance, and reduced production costs. Techniques such as advanced plastic injection molding have emerged as essential solutions, enabling manufacturers to quickly achieve exceptional accuracy and precision. These rapid molding approaches allow businesses to meet rigorous quality standards without delays or added costs, ultimately driving innovation and competitiveness.

Defining High Accuracy in Rapid Molding

Accuracy in manufacturing refers to how closely a finished product conforms to intended design specifications. Precision, often synonymous with accuracy, specifically denotes consistency and repeatability in part production. Achieving high accuracy ensures each manufactured part consistently matches design criteria, directly impacting product reliability and performance.

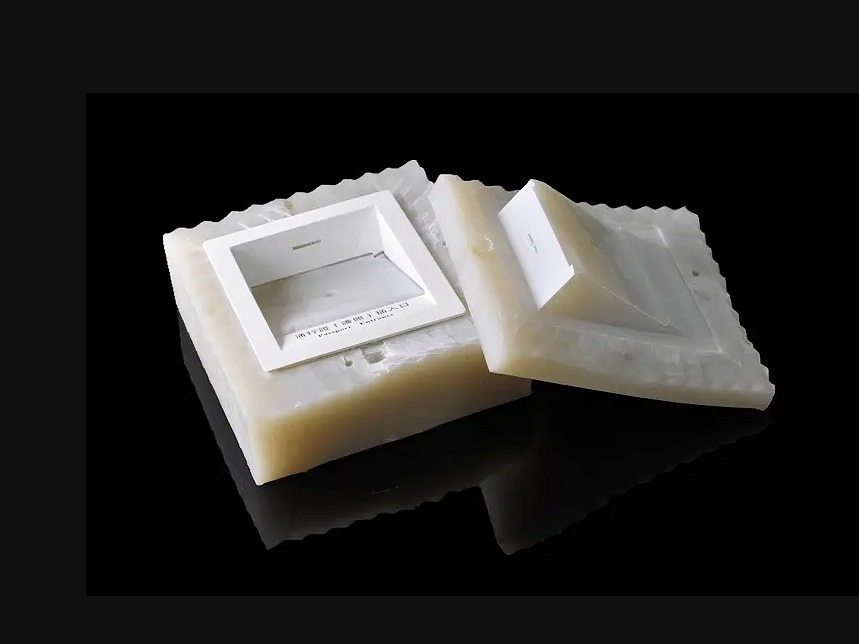

High accuracy in rapid molding demands precision throughout every step, from mold creation using methods like CNC machining to final part production. Accurate molds minimize the need for secondary finishing processes, significantly reducing production timelines and costs compared to traditional metal injection molding.

Techniques for Achieving Precision in Rapid Molding

Precision in rapid molding involves combining advanced techniques and optimized processes:

Optimized Mold Design and Engineering: Accurate mold design directly impacts precision. Employing design-for-manufacturing (DFM) principles, advanced CAD software, and predictive simulation ensures every mold dimension accurately reflects the final product, mitigating inaccuracies before manufacturing begins.

Precision Machining Processes: Advanced manufacturing techniques, such as multi-axis CNC machining, ensure molds achieve tight tolerances. Precise machining guarantees that mold surfaces replicate intended designs closely, minimizing variation in molded parts.

Selection of Materials for Dimensional Stability: Choosing materials with superior dimensional stability, such as thermoplastics like ABS, polycarbonate, or specialized metal alloys like zinc alloys, reduces shrinkage and warpage, ensuring consistent dimensions throughout production.

Advantages of Precision Rapid Molding

Precision rapid molding provides critical benefits:

Consistent Quality and Reliability: Precision molding produces highly consistent parts, drastically reducing variations. This consistency significantly enhances reliability, ensuring superior product performance.

Reduced Errors and Rework: Precision molding minimizes production errors, significantly reducing the need for costly rework or adjustments. Fewer errors directly lead to reduced costs and shorter turnaround times than traditional methods like gravity casting.

Enhanced Product Performance and Lifespan: Products manufactured through precision molding demonstrate improved performance and increased durability. Accurate dimensions ensure components precisely fit and function, significantly increasing the lifespan and efficacy of final products compared to processes such as sand casting.

Real-world applications of High Precision Rapid Molding

Precision rapid molding plays essential roles across various industries:

Automotive Sector: In automotive manufacturing, rapid molding precision is critical for producing intricate, high-tolerance components, including connectors, custom housings, and precision automotive parts. Accurate molding directly contributes to vehicle safety, reliability, and performance, reducing production timelines.

Electronics Industry: Electronic components require exceptional precision, especially in connectors, switches, and casings. Utilizing precise rapid molding methods ensures components function effectively, improving reliability and overall performance compared to traditional metal stamping.

Medical Device Industry: Medical devices demand extreme accuracy due to their critical use. Precision molding processes meet these rigorous requirements, efficiently producing medical components like surgical instruments, customized implants, and diagnostic devices with consistent quality and compliance.

Challenges in Achieving High Precision and Solutions

Achieving high precision poses specific challenges, such as shrinkage, warpage, and inconsistent molding processes:

Common Issues Affecting Mold Accuracy: Shrinkage and warpage frequently result from improper material selection, inadequate mold temperatures, or flawed mold designs. Such inaccuracies can compromise product integrity and reliability.

Strategies to Mitigate Inaccuracies and Maintain Precision: To overcome these challenges, manufacturers should focus on precise mold design, rigorous material selection criteria, and controlled molding conditions. Advanced process controls, routine mold maintenance, and predictive process simulations substantially reduce inaccuracies, ensuring consistent high-precision molded parts.

Conclusion

Achieving high precision through rapid molding is crucial for companies aiming to remain competitive and innovative. Precision molding guarantees consistent quality, reliability, reduced errors, and enhanced product durability. Manufacturers embracing precision-focused rapid molding strategies are ideally positioned to meet rigorous accuracy standards demanded by today’s industries.

Related FAQs:

How does mold design affect the accuracy of molded parts?

What materials provide the highest dimensional stability in rapid molding?

Can rapid molding achieve the same precision as traditional molding methods?

How do precision molding techniques reduce manufacturing costs?

What industries require the highest accuracy from rapid molding processes?