Embracing Versatility: Exploring PCM's Wide Range of Material Capabilities

Introduction

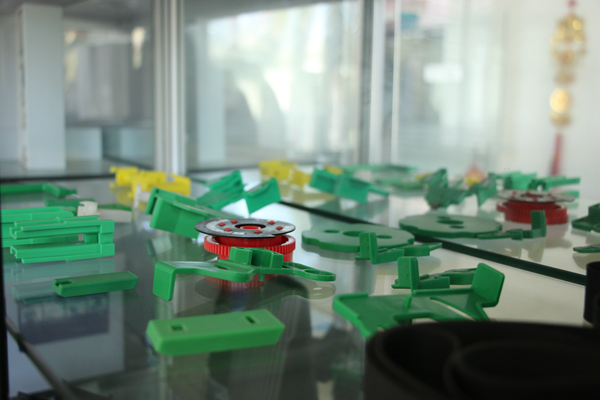

Powder Compression Molding (PCM) has become an essential technology in advanced manufacturing, offering exceptional versatility across various industries. PCM provides an efficient way to produce precise, high-quality custom parts, especially beneficial when working with diverse materials. This versatility allows manufacturers to adapt quickly to evolving market demands and stringent product requirements.

Section 1: Understanding Powder Compression Molding (PCM)

Powder Compression Molding is a manufacturing process involving compressing powdered materials into a mold, followed by heating (sintering) to produce a solid, durable component. PCM stands out due to its cost-effectiveness, accuracy, scalability, and ability to handle complex geometries in custom parts. Industries ranging from automotive and aerospace to medical and consumer electronics manufacturing significantly benefit from PCM.

Section 2: Metals and Alloys in PCM

Metals and alloys are foundational materials in PCM, valued for their strength, durability, and versatility. Key materials include:

Stainless Steel: Offers excellent corrosion resistance, strength, and durability, making it suitable for automotive, medical devices, and consumer electronics.

Tool Steel: Renowned for its hardness and resistance to wear, essential for manufacturing tooling components and machinery parts.

Low Alloy Steel: Provides strength, toughness, and affordability, commonly used in automotive and industrial applications.

Magnetic Alloy: Crucial for electromagnetic applications, often found in electronics, automotive sensors, and industrial motors.

Metal-based PCM components are highly favored for their reliability and adaptability in demanding applications, providing manufacturers with robust, high-performing metal parts.

Section 3: Ceramic Materials in PCM

Ceramic materials expand PCM’s capabilities, particularly in high-performance and high-temperature environments. Key ceramic materials include:

Alumina (Al2O3): Known for its exceptional hardness, chemical resistance, and thermal stability, widely utilized in electronics and medical implants.

Zirconia (ZrO2): Offers excellent fracture toughness and wear resistance, making it ideal for dental implants, cutting tools, and precision bearings.

Silicon Carbide (SiC): Renowned for its thermal conductivity and mechanical strength, perfect for applications in aerospace, automotive, and semiconductor industries.

Silicon Nitride (Si3N4): Appreciated for its strength at high temperatures, low thermal expansion, and resistance to thermal shock, frequently used in advanced aerospace components and high-temperature bearings.

Ceramic PCM components allow manufacturers to tackle specialized applications with unmatched precision and reliability, reinforcing PCM’s position as a versatile ceramic manufacturing solution.

Section 4: Plastics and Thermoplastics in PCM

Plastics further diversify PCM’s applicability:

ABS: Widely used in automotive and consumer electronics for its toughness and moldability.

PEEK: Exceptional thermal stability and strength, suitable for medical and aerospace.

Nylon (PA): Renowned for durability and flexibility, favored in automotive parts and textiles.

Polycarbonate (PC): High impact resistance, popular in safety equipment and medical devices.

Section 4: Superalloys and Advanced Materials

PCM also efficiently accommodates superalloys, renowned for their exceptional performance in challenging environments:

Inconel Alloys: Ideal for high-temperature aerospace and automotive applications.

Haynes Alloys: Offer extraordinary heat resistance and durability, utilized prominently in aerospace components.

Section 5: Sustainability and Material Efficiency in PCM

PCM significantly contributes to sustainable manufacturing practices:

Reduces waste through precision and efficient material utilization.

Promotes eco-friendly manufacturing processes with minimal environmental impact.

Case studies demonstrate PCM's effectiveness in achieving sustainable production goals.

Section 6: Comparative Analysis: PCM vs. Other Molding Methods

When compared to traditional molding methods, PCM demonstrates superior versatility:

PCM vs. Injection Molding: PCM is superior for precision with complex and dense components.

PCM vs. Die Casting: PCM offers better flexibility with material selection.

PCM vs. CNC Machining: PCM provides significant cost advantages, especially for complex designs and mass production.

Conclusion

PCM’s broad spectrum of material capabilities empowers manufacturers to innovate and meet stringent industrial demands. As technology advances, PCM is expected to incorporate even more sophisticated materials, further expanding its applications and reinforcing its value across industries.

Explore how Neway Precision’s PCM services can enhance your manufacturing capabilities. Discover more about our wide range of materials and expert solutions today.