Eco-Smart Manufacturing: The Environmental and Economic Advantages of Aluminum Die Casting

Introduction

Eco-friendly manufacturing is increasingly vital as companies strive to reduce their environmental impact while maintaining economic efficiency. Among various sustainable production methods, aluminum die casting is a highly effective solution, offering both environmental sustainability and substantial cost benefits. This method minimizes waste and energy usage and enhances production efficiency, making it ideal for industries focused on eco-smart manufacturing.

Understanding Aluminum Die Casting

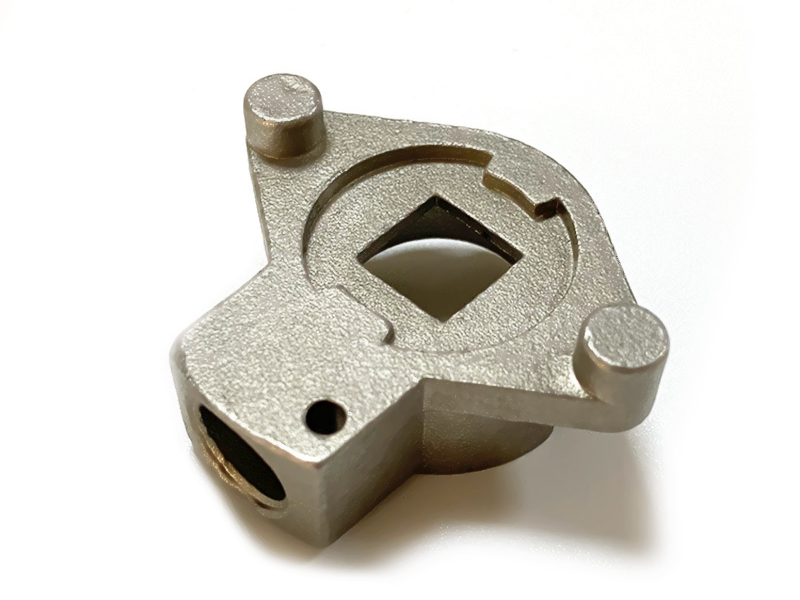

Aluminum die casting is a precision manufacturing process where molten aluminum alloy, such as A380, A360, or ADC12, is injected under high pressure into a steel mold (die). This approach results in complex, dimensionally accurate parts with excellent surface finishes, significantly outperforming traditional methods such as sand casting and investment casting in terms of efficiency and precision.

Environmental Advantages of Aluminum Die Casting

High Recyclability and Minimal Waste

One key advantage of aluminum die casting is the recyclability of aluminum, which retains its properties indefinitely when recycled. This process significantly reduces waste by precisely controlling material usage, aligning closely with sustainable manufacturing principles. The minimal waste and high recyclability make aluminum die casting particularly beneficial for industries pursuing eco-friendly practices.

Energy Efficiency

Aluminum die casting uses considerably less energy than conventional manufacturing processes, directly contributing to lower carbon emissions. This energy efficiency aligns with global sustainability targets and significantly reduces the environmental footprint of manufacturers, particularly in energy-intensive sectors such as automotive manufacturing.

Reduced Carbon Footprint

Due to aluminum's lightweight nature, die-casting products often reduce fuel consumption and emissions, which is especially critical in the automotive and aerospace industries. The combination of precision manufacturing and lightweight materials directly contributes to substantial carbon footprint reductions, making it an integral part of sustainable supply chains.

Sustainable Sourcing

The abundance and recyclability of aluminum facilitate sustainable sourcing practices, reducing dependency on virgin materials. Aluminum die casting supports responsible sourcing initiatives, reinforcing its position within modern eco-conscious manufacturing frameworks.

Economic Benefits of Aluminum Die Casting

Cost-Effectiveness

Aluminum die casting significantly reduces manufacturing costs through efficient material usage and minimized secondary operations. Fewer machining steps and less material waste result in tangible cost savings, providing a clear economic advantage over traditional manufacturing methods such as precision machining.

Shortened Production Cycles

The high speed and efficiency of aluminum die casting enable rapid production cycles, allowing businesses to swiftly scale production in response to market demands. Faster production times mean reduced labor and inventory costs, directly benefiting profitability and market responsiveness.

Enhanced Durability and Lower Maintenance

Aluminum die-casted products exhibit superior mechanical strength and resistance to corrosion, significantly lowering maintenance and repair costs over their lifecycle. Industries such as aerospace and transportation benefit greatly from durable, long-lasting components, reducing total operational expenses.

Competitive Market Advantage

Companies adopting aluminum die casting can effectively meet demands for high-quality, sustainable products, gaining substantial market advantages. This manufacturing approach supports sustainability objectives and enhances brand reputation and customer loyalty through a demonstrated commitment to environmental responsibility.

Real-World Applications and Industry Examples

Automotive Industry

Aluminum die casting revolutionizes automotive production by creating lightweight, robust components like engine blocks and transmission housings. These parts reduce vehicle weight, increase fuel efficiency, and enhance overall performance, contributing directly to automotive sustainability goals.

Electronics and Consumer Products

In consumer electronics, aluminum die casting enables the production of precision components such as laptop frames and smartphone casings. Aluminum's excellent thermal conductivity enhances device cooling and durability, significantly improving performance and extending the product lifecycle.

Renewable Energy Components

Renewable energy manufacturers use aluminum die casting for components like wind turbine housings and solar panel brackets. Aluminum's durability and lightweight properties make it ideal for harsh environmental conditions, ensuring long-term reliability and sustainable energy production.

Aerospace and Transportation

Aluminum die casting provides aerospace and transportation sectors with lightweight yet durable components crucial for safety and efficiency. Aircraft and railcar parts manufactured through die casting enhance overall performance, significantly supporting these industries' environmental sustainability objectives.

Addressing Common Die Casting Challenges

Manufacturers may face challenges such as porosity or inconsistent surface finishes. Employing advanced casting simulation software and meticulous mold designs is critical to overcome these issues. Partnering with experienced die casting specialists further ensures production efficiency and high-quality results.

Future Trends and Innovations

Emerging innovations, such as new recyclable aluminum alloys and automation technologies like robotics and AI, promise further enhancements in aluminum die casting efficiency. These advancements will enable even more precise, sustainable, and cost-effective manufacturing, paving the way for expanded industry applications.

Conclusion

Aluminum die casting exemplifies eco-smart manufacturing by providing significant environmental and economic advantages. Industries aiming to reduce environmental impact and enhance profitability should explore this manufacturing process to achieve sustainability and competitive advantages. Now is the time to embrace aluminum die casting and drive forward into a greener, more sustainable manufacturing future.

FAQs:

What makes aluminum die-casting environmentally sustainable?

How does aluminum die casting contribute to manufacturing cost efficiency?

Which industries benefit the most from adopting aluminum die casting?

Are there specific aluminum alloys preferred for eco-smart die casting?

What are the future innovations expected in aluminum die-casting technology?