Eco-Smart Custom Parts: Advancing Sustainability in Gravity Casting Manufacturing

Introduction

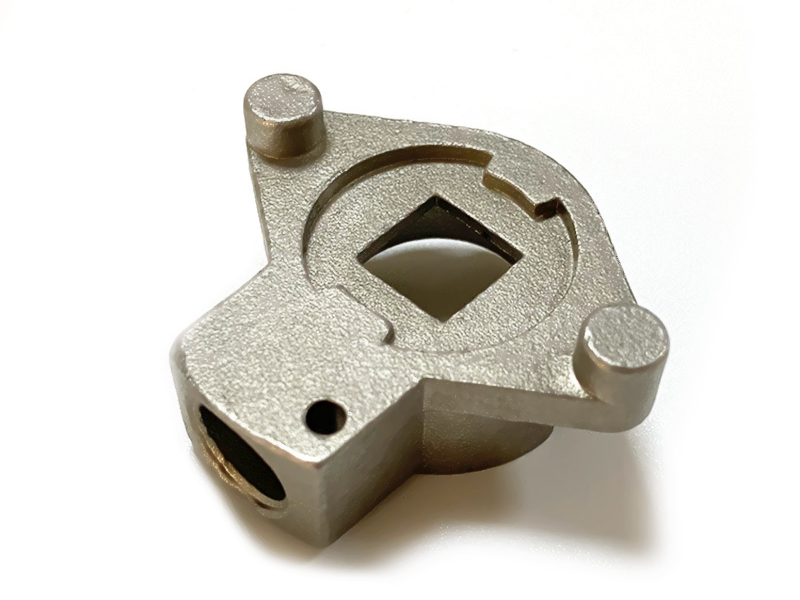

Sustainability is increasingly essential in today's manufacturing landscape, where reducing environmental impacts has become a global imperative. Gravity casting, an efficient and versatile metal casting technique, supports eco-friendly manufacturing through eco-smart custom parts. This method leverages recyclable aluminum alloys, reduces energy consumption, and minimizes waste, making it ideal for companies committed to eco-smart manufacturing. This blog explores gravity casting’s contributions to sustainability, its advantages, and practical industry applications.

Sustainability in Gravity Casting

Gravity casting involves pouring molten metal into molds using gravity, inherently supporting sustainability. Unlike high-pressure die casting methods, gravity casting uses less energy and generates fewer emissions.

Common materials in gravity casting include:

Aluminum alloys (recyclable and energy-efficient)

Brass and bronze (reusable and durable)

Iron and steel alloys (highly recyclable)

Gravity casting’s environmental profile benefits from reduced energy consumption, fewer emissions, and excellent recyclability.

Advantages of Eco-Smart Custom Parts

Resource Efficiency and Waste Reduction

Gravity casting significantly reduces waste due to precise molds and minimal machining. Using recycled materials further enhances efficiency.

Enhanced Material Recyclability

Gravity casting materials, especially aluminum alloys, support closed-loop recycling systems, minimizing raw materials and waste.

Energy-Efficient Production

Gravity casting processes run at lower temperatures, reducing energy requirements compared to intensive pressure-casting techniques, saving energy, and lowering emissions.

Durability and Longevity

Eco-smart custom gravity cast parts offer outstanding durability, significantly reducing replacements and minimizing environmental impact.

Implementing Sustainable Practices in Gravity Casting

Sustainable Material Sourcing

Responsibly sourcing and prioritizing sustainably produced alloys substantially improves the environmental impact of gravity casting.

Efficient Mold Design and Production

Optimizing mold designs maximizes resource efficiency, reduces waste, and promotes long-term mold reusability.

Energy-Efficient Techniques

Adopting energy-efficient furnaces, precise temperature control, and automated pouring reduces energy consumption and environmental impact.

Recycling and Reclamation

Implementing robust recycling methods for molds and metal remnants reduces production waste, enhancing sustainability and reducing manufacturing costs.

Real-World Applications and Success Stories

Automotive Industry

Automotive companies use gravity casting for components like cylinder heads and braking systems, benefiting from energy savings and recyclability.

Renewable Energy Sector

Gravity casting is essential for manufacturing wind turbine and solar components, aligning perfectly with renewable energy’s sustainability objectives.

Consumer Products

Manufacturers prefer gravity casting for producing consumer items like cookware and hardware. Eco-conscious consumers appreciate products made using sustainable practices.

Infrastructure and Construction

Gravity casting sustainably produces architectural fittings and structural elements, enhancing eco-friendly construction practices.

Overcoming Sustainability Challenges in Gravity Casting

Sustainable Material Sourcing

Prioritizing sustainable metal sourcing addresses ecological impacts linked to resource extraction.

Efficient Mold Design and Production

Sustainability improves through optimized mold design and reuse, minimizing resource consumption and waste.

Energy Efficiency

Energy-efficient techniques such as automated pouring systems significantly reduce energy usage.

Recycling and Reclamation

Effective recycling of mold materials and metal scraps enhances sustainability while reducing production costs.

Future Trends in Eco-Smart Gravity Casting

Technological Advancements

Emerging technologies like casting simulations and energy-efficient furnaces promise reduced waste and lower emissions.

Sustainable Alloys and Innovations

Innovative eco-friendly alloys and recycling advancements are enhancing gravity casting’s sustainability.

Automation

Automated casting processes promise improved precision, reduced waste, and greater sustainability across manufacturing sectors.

Real-World Applications and Success Stories

Automotive Industry

Eco-smart gravity casting benefits automotive manufacturers by producing components like cylinder heads and brake systems.

Renewable Energy Sector

Gravity casting sustainably manufactures critical components for renewable energy systems, enhancing the sector's eco-friendly credentials.

Consumer Products

Due to sustainable production practices, eco-conscious consumers value gravity-cast consumer products, such as cookware and hardware.

Infrastructure and Construction

Gravity casting is integral to creating durable and sustainable architectural fixtures, contributing positively to eco-friendly construction practices.

Overcoming Sustainability Challenges

Common Challenges

Manufacturers commonly face issues like sand disposal, emissions control, and waste management, which may threaten sustainability if unmanaged.

Best Practices

Regular sustainability audits, robust recycling programs, and expert-led process improvements effectively address environmental challenges and ensure regulatory compliance.

Compliance and Certification

Acquiring sustainability certifications ensures manufacturers adhere to global standards, enhancing their credibility and environmental stewardship.

Future Trends in Gravity Casting

Technological Advancements

Emerging technologies, including advanced casting simulations, promote sustainability by reducing waste and energy demands.

Sustainable Innovations

Ongoing research into sustainable alloys and advanced materials continues to enhance environmental performance.

Automation and Efficiency

Increased automation in gravity casting promises substantial sustainability gains through efficiency, waste reduction, and improved precision.

Conclusion

Gravity casting, when aligned with eco-smart practices, offers significant sustainability advantages. Manufacturers adopting eco-friendly sourcing, resource efficiency, and innovative technologies can effectively enhance their environmental credentials, reduce operational costs, and position themselves strategically in the marketplace. Eco-smart gravity casting contributes positively to environmental sustainability, economic benefits, and competitive market positioning.

FAQs:

How does gravity casting contribute to environmental sustainability?

What are the primary sustainability benefits of eco-smart custom gravity cast parts?

Which industries benefit most from sustainable gravity casting practices?

What challenges do manufacturers face when adopting sustainable gravity casting?

How are technological advancements shaping the future of eco-smart gravity casting?