Die Casting vs. Sand Casting: Making the Right Choice

Brief Overview of Casting Processes

Casting processes are pivotal in custom manufacturing, offering a versatile means of creating complex and intricate metal components. Casting methods, such as die casting and sand casting, are indispensable in various industries, including Consumer Electronics, Telecommunication, Lighting Solutions, Power Tools, and Locking Systems.

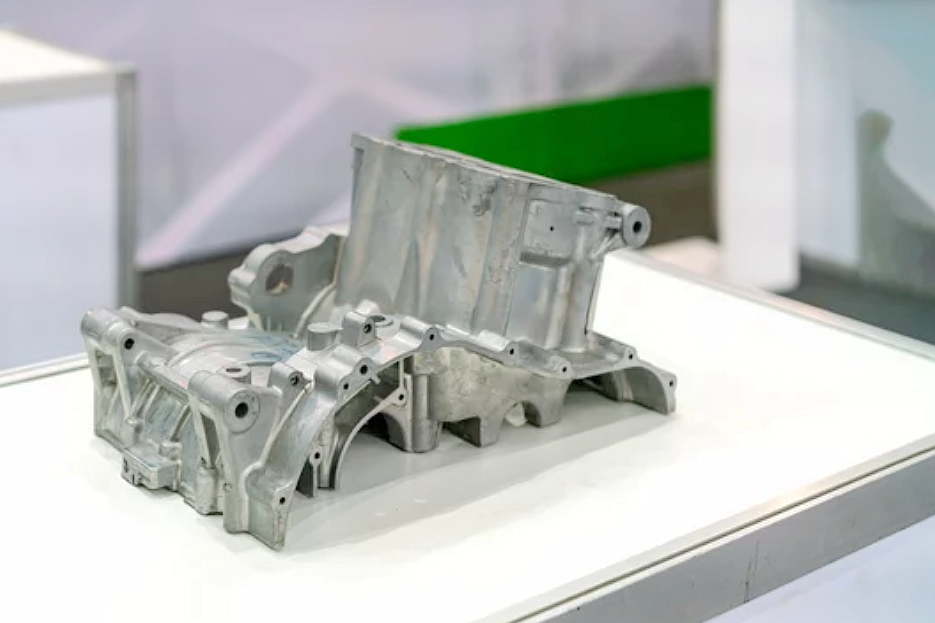

Die casting is a precision-oriented technique known for its high-precision capabilities with tolerances as tight as 0.1 mm. It involves injecting molten metal, often aluminum or zinc, into steel molds under high pressure, resulting in products characterized by superior surface finish and dimensional accuracy.

On the other hand, sand casting, a more traditional approach, relies on sand molds to shape metal parts. While it may not match die casting's precision, sand casting excels in versatility, cost-effectiveness, and suitability for larger, more complex components. It applies in industries such as Lighting Solutions and Power Tools, where durability and robustness are prized over absolute precision. In essence, the comparison between die casting and sand casting underscores the significance of selecting the proper casting process tailored to the specific requirements of the industry and the intended application.

Die Casting Process

Die casting starts with the preparation of the die, typically made of steel. The die consists of two halves, the cover die, and the ejector die, that is precisely machined to shape the desired part. Molten metal, often aluminum, zinc, or magnesium, is heated until it reaches the desired temperature and consistency. In the cold chamber die-casting method, the molten metal is ladled into the chamber and injected into the die cavity. At the same time, in the hot chamber method, the chamber is submerged in the molten metal, allowing for a continuous casting process. Once the metal fills the cavity and solidifies, the die opens, and the component is ejected.

Materials Used:

Die-casting materials are chosen for their excellent flowability and dimensional stability during the process. Common metals and alloys include aluminum, known for its lightweight properties and corrosion resistance, zinc for its excellent casting properties, and magnesium for its exceptional strength-to-weight ratio.

Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Shear Strength (MPa) | Impact Strength (J) | Fatigue Strength (MPa) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Melting Range (°C) |

276 | 241 | 95 | 207 | 24 | 96 | 167 | 2.7 | 582-652 | |

185 | 145 | 68 | 115 | 17 | 110 | 201 | 2.7 | 606-652 | |

572 | 503 | 150 | 331 | 32 | 159 | 130 | 2.8 | 477-635 | |

270 | 200 | 70 | 170 | 35 | 75 | 167 | 2.68 | 540-650 | |

215 | 150 | 60 | 125 | 15 | 75 | 96 | 2.7 | 540-650 | |

A360 | 216 | 150 | 60 | 125 | 15 | 75 | 96 | 2.68 | 557-610 |

380 | 260 | 215 | 75 | 165 | 22 | 85 | 156 | 2.73 | 540-660 |

310 | 260 | 80 | 186 | 18 | 100 | 149 | 2.72 | 570-640 | |

295 | 255 | 87 | 190 | 25 | 100 | 96 | 2.7 | 570-640 | |

240 | 215 | 80 | 190 | 15 | 85 | 116 | 2.68 | 593-620 | |

413 | 295 | 255 | 87 | 190 | 25 | 100 | 96 | 2.73 | 540-650 |

A413 | 290 | 241 | 84 | 186 | 30 | 90 | 96 | 2.71 | 570-630 |

Advantages of Die Casting:

High Precision: Die casting achieves tight tolerances, with precision values as low as 0.1 mm, making it ideal for industries where exact dimensions are crucial, such as Aerospace and Medical Devices.

Minimal Post-Processing: Die-cast parts often require minimal finishing, as the process yields products with smooth surfaces and fine details, reducing the need for extensive post-production work and enhancing cost-effectiveness.

Rapid Production: Die casting allows for high-volume production with shorter cycle times. This speed makes it suitable for industries like E-Mobility, where the demand for components is high and production efficiency is vital.

In conclusion, die casting is a versatile and efficient manufacturing process catering to various industries. Its ability to produce high-precision components with minimal post-processing and rapid production capabilities makes it a cornerstone of modern manufacturing. It contributes significantly to the success of industries such as E-Mobility and Aerospace.

Sand Casting Process

Sand casting involves molding from sand and a binding agent, typically clay. The process begins with a pattern, a replica of the desired part, placed in sand to create a mold cavity. The mold is then split into two halves – the cope and drag. After removing the pattern, molten metal, often aluminum, brass, or iron, is poured into the mold cavity. Once the metal cools and solidifies, the mold is opened, and the casting is removed, ready for further processing.

Types of Sand Casting

Green Sand Casting: The most common type, it uses a mixture of sand, clay, and water as the mold material. It's cost-effective and versatile.

Resin Sand Casting: A resin is added to the sand mixture to improve mold strength and surface finish. This type is suitable for more intricate and detailed parts.

Shell Molding: In this method, sand is mixed with a thermosetting resin and then heated until it hardens. It results in high precision and dimensional stability.

Materials Used

Sand casting materials vary widely but commonly include metals like aluminum, brass, bronze, and iron. The choice depends on the desired mechanical properties, cost, and application requirements.

Advantages of Sand Casting

Versatility for Large Parts: Sand casting excels in producing large and bulky components, making it indispensable for industries like Power Tools and Lighting Solutions.

Low Tooling Costs: Compared to processes like die casting, sand casting incurs lower tooling and setup costs, making it economical for small to medium production runs.

Complex Geometries: Sand casting allows for creating intricate and complex shapes with relative ease, offering design freedom in industries where unique forms are critical.

In conclusion, sand casting offers a cost-effective and flexible solution for manufacturing a wide range of parts, particularly suited for significant components and complex designs. Its ability to accommodate various materials and its cost-efficiency make it a valuable process in industries such as Locking Systems and Power Tools.

Casting Process Comparison

Tooling Requirements: Die casting requires complex, precision-made dies, which can be expensive. In contrast, sand casting relies on relatively simple patterns and molds, reducing initial tooling costs.

Surface Finish: Die casting offers an excellent surface finish, often requiring minimal post-processing. Sand casting can result in varying surface finishes, with some parts needing additional work to achieve the desired smoothness.

Tolerances: Die casting excels in achieving high precision with tolerances as tight as 0.1 mm. Sand casting typically offers moderate tolerances, which can vary based on factors like the part's complexity and the operator's skill.

Production Rate: Die casting boasts high production rates and shorter cycle times, making it ideal for industries with high demand for parts. Sand casting generally has lower production rates due to longer cycle times, making it better suited for smaller production volumes.

Waste and Sustainability: Die casting is material-efficient with minimal waste, and scrap can often be recycled. Sand casting generates more material waste, primarily from the disposal of used sand. However, sand can be recycled, and some processes, like shell molding, are more sustainable. Both processes require energy to heat and melt metal.

Aspect | Die Casting | Sand Casting |

|---|---|---|

Tooling Requirements | High initial tooling costs | Lower initial tooling costs |

Complex dies required | Simple patterns and molds | |

Surface Finish | Excellent surface finish | Surface finish can vary |

Smooth and precise | May require post-processing | |

Tolerances | High precision, <0.1 mm | Moderate precision varies |

Suitable for tight tolerances | Tolerances typically >0.5 mm | |

Production Rate | High production rates | Lower production rates |

Shorter cycle times | Longer cycle times | |

Waste and Sustainability | Material efficient | Higher material waste |

Minimal material waste | Potential for sand disposal | |

Recyclable scrap | Energy-intensive |

Custom Casting Applications

Industries Where Die Casting Is Preferred

Automotive: Die casting is widely used in the automotive industry for manufacturing engine components, transmission parts, and structural components. It offers high precision and excellent mechanical properties, making it ideal for producing critical automotive parts.

Consumer Electronics: This industry relies on die casting to manufacture lightweight and intricately designed components like smartphone cases, laptop shells, and camera bodies. The method's ability to create precise, thin-walled structures is a significant advantage.

Telecommunication: Die casting is preferred for producing components in telecommunications equipment, such as antenna housings, connectors, and brackets. This sector's capability to achieve tight tolerances and consistent quality is crucial.

Aerospace: Aerospace applications demand high-quality, lightweight components with minimal porosity. Die casting is used to manufacture aircraft components like turbine blades, housings, and structural parts, where precision and strength are paramount.

Medical Devices: The medical industry benefits from die casting for producing instrument casings, device components, and hardware due to its ability to maintain strict tolerances and surface finishes.

Examples of Products Made Using Die Casting

Aluminum alloy engine blocks for automotive applications.

Magnesium alloy laptop shells for consumer electronics.

Zinc alloy connectors for telecommunication devices.

High-strength aluminum alloy aircraft components.

Precision-machined aluminum alloy parts for medical devices.

Industries Where Sand Casting Is Preferred

Heavy Machinery: Sand casting is commonly used to produce large and heavy machinery components, such as engine blocks for industrial equipment, gears, and pulleys. Its ability to handle substantial sizes and weights is advantageous.

Architectural: Sand casting is favored for producing decorative and ornamental metalwork used in architectural applications, including gates, railings, and sculptures. Its versatility allows for intricate designs.

Art and Craft: Artistic and craft industries often use sand casting to create unique metal sculptures, statues, and artistic pieces due to their flexibility in shaping complex forms.

Power Generation: Sand casting is employed in the power generation industry to manufacture turbine blades, casings, and other critical components. It can handle the large sizes and intricate shapes required in this sector.

Marine: Components for marine applications, such as propellers, ship parts, and marine fittings, are often produced using sand casting, as it provides durability and corrosion resistance.

Examples of Products Made Using Sand Casting

Iron engine blocks for heavy machinery.

Decorative iron gates and railings.

Bronze sculptures and artistic pieces.

Steel turbine blades for power generation.

Brass marine fittings and components.

In summary, die casting excels in industries requiring high precision and complex geometries, such as automotive and consumer electronics. On the other hand, sand casting shines in applications where versatility, cost-effectiveness, and the ability to handle larger sizes are paramount, such as heavy machinery and architectural metalwork. The choice between these casting methods depends on the specific needs of each industry and the intended application.

Decision Factors

The choice between die casting and sand casting is a critical decision in manufacturing, and it should be based on a careful evaluation of several key factors to ensure the best fit for a given project.

Project-Specific Factors

Part Size: Die casting is often preferred for minor, intricate components requiring high precision and tight tolerances. Its ability to achieve fine details and smooth surfaces makes it suitable for parts in industries like Consumer Electronics and Telecommunication.

Part Complexity: Die casting better serves complex geometries due to their precision capabilities. However, sand casting's flexibility may be advantageous if a part has irregular shapes or internal cavities that are challenging to create with dies.

Quantity: High production volumes are typically more cost-effective with die casting due to its shorter cycle times and high production rates. Sand casting may be preferable for smaller production runs or one-off prototypes.

Budgetary and Timeline Constraints

Initial Tooling Costs: Die casting often incurs higher tooling costs due to the complexity of creating precision dies. Sand casting offers a more budget-friendly option with its more straightforward pattern and mold requirements.

Production Costs: Die casting can be cost-effective for large-scale production, but sand casting may be more economical for smaller quantities. Consider the overall production budget and cost per unit.

Timeline: Die casting generally has shorter cycle times, making it suitable for projects with tight deadlines. Sand casting, while versatile, may require longer lead times due to the creation of molds or patterns.

Material Selection Considerations

Material Properties: Consider the specific material requirements of the part. Die casting is well-suited for materials like aluminum, zinc, and magnesium, while sand casting accommodates a broader range, including iron, brass, and bronze.

Mechanical Properties: Evaluate the mechanical properties needed, such as strength, weight, and corrosion resistance. Die casting can provide superior mechanical properties for specific materials.

Cost of Materials: Materials for die casting can be more expensive than those used in sand casting—factor in material costs when deciding.

A comprehensive assessment of these factors will guide the choice between die casting and sand casting. For instance, producing intricate, high-precision components for the Consumer Electronics industry may favor die casting due to the need for precision and high volumes. Conversely, a specialized, low-volume project with unique geometry for a Lighting Solutions component might find sand casting more cost-effective.

Key Differences and Considerations

In conclusion, the choice between die casting and sand casting hinges on several key differences and crucial considerations. Each casting method offers distinct advantages and is better suited for specific industries and project requirements.

Die casting is favored for its high precision, excellent surface finish, and suitability for intricate components. It excels in industries like automotive, consumer electronics, and aerospace. In contrast, sand casting's versatility shines in applications where large parts, unique geometries, and cost-effectiveness are essential, such as heavy machinery, architectural metalwork, and artistic creations.

When selecting a casting method, project-specific factors such as part size, complexity, and quantity play a vital role. Budgetary constraints and timelines, as do material requirements and mechanical properties, impact the decision.