Cost-Effectiveness: How 3D Printing Reduces Upfront Manufacturing Costs

Introduction:

In today's fast-paced manufacturing environment, businesses constantly seek ways to enhance efficiency and reduce expenses. A revolutionary solution is 3D printing, also known as additive manufacturing, which significantly lowers upfront costs compared to traditional methods like injection molding. This blog explores how additive manufacturing achieves substantial cost savings, highlighting why businesses should consider adopting this transformative technology.

Overview of 3D Printing in Manufacturing

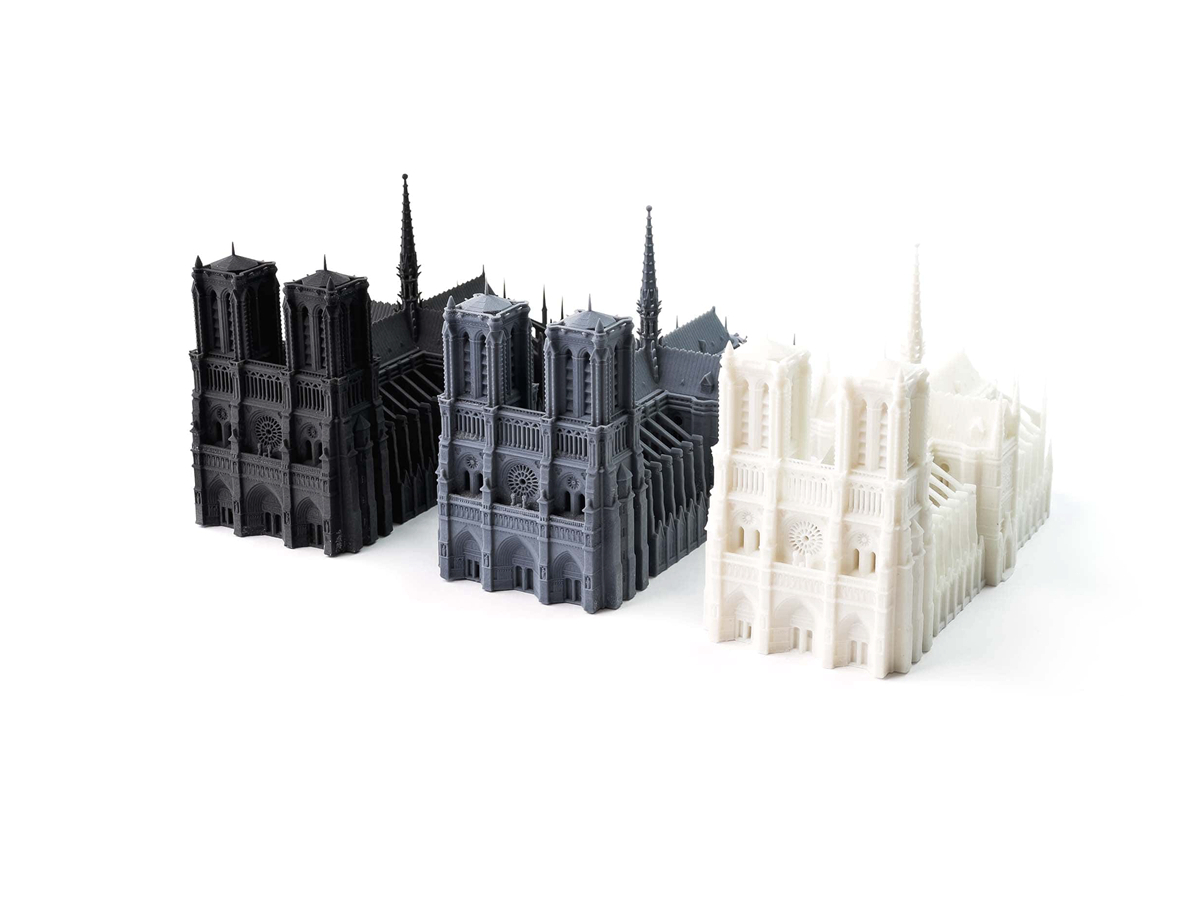

3D printing creates objects layer-by-layer directly from digital designs, using technologies such as:

Fused Deposition Modeling (FDM): An affordable and efficient method ideal for quick prototypes or small-batch components.

Selective Laser Sintering (SLS): Utilizes lasers to fuse powdered materials into strong, precise components.

Stereolithography (SLA): Delivers highly detailed prototypes with excellent surface finishes suitable for precision-driven applications.

Multi Jet Fusion (MJF): Produces complex parts at high speeds, ideal for end-use production scenarios.

Each of these technologies offers distinct advantages, enabling manufacturers to find optimal solutions tailored to specific applications.

Reducing Tooling Costs

Traditional manufacturing processes like plastic injection molding require significant upfront investments in tooling and molds. Conversely, 3D printing dramatically reduces these initial costs by:

Eliminating Mold and Tooling Expenses: Since additive manufacturing builds parts directly from digital files, manufacturers bypass expensive molds entirely.

Cost-Effective Prototyping: Companies can rapidly iterate and test designs without additional tooling expenditures, significantly lowering prototyping costs.

Automotive manufacturers commonly leverage rapid prototyping via 3D printing to evaluate multiple design variations affordably before committing to mass production tooling.

Lower Material Waste

Compared to traditional subtractive processes like CNC machining, additive manufacturing reduces material waste significantly:

Efficient Material Usage: By building parts layer-by-layer, 3D printing uses materials precisely where needed, minimizing unnecessary consumption.

Economic and Environmental Advantages: Less material waste translates into cost savings and reduces disposal and environmental impact, enhancing overall production sustainability.

Industries such as aerospace frequently utilize selective laser melting (SLM) to manufacture lightweight components, optimizing material usage and significantly reducing costs.

Faster Prototype Development

Rapid prototyping enabled by 3D printing streamlines the product development process, reducing both time and costs associated with bringing products to market:

Shorter Development Cycles: Quick iteration and testing accelerate product refinement, minimizing development timelines.

Cost Savings from Early Error Detection: Identifying and correcting design flaws early prevents costly errors during full-scale manufacturing.

Medical device companies widely use 3D printing prototyping services to validate functionality and safety, achieving faster, more economical product launches.

Reduced Inventory and Storage Costs

Traditional manufacturing necessitates large inventories, leading to substantial storage and management expenses. Additive manufacturing solves this by:

On-Demand Manufacturing: 3D printing allows production of parts precisely when needed, greatly reducing excess inventory.

Lower Storage and Logistics Costs: On-demand production decreases reliance on warehousing, significantly cutting associated storage and logistics expenses.

Industries such as automotive parts manufacturing have embraced additive manufacturing, substantially lowering inventory-related costs.

Streamlining Production and Market Entry

3D printing accelerates the journey from concept to market, providing manufacturers with significant competitive advantages:

Rapid Product Development: Shorter production cycles enable rapid market responsiveness, positioning companies ahead of competitors.

Cost Efficiency: Faster development reduces resource usage associated with extended product timelines.

Consumer electronics companies often employ 3D printing alongside processes like CNC machining prototyping to quickly launch innovative products, capturing market opportunities effectively.

Scalability and Flexibility

Manufacturers benefit from the scalability and adaptability of additive manufacturing, especially when responding to dynamic market demands or customized orders:

Adaptable Designs: Quickly modify designs without expensive retooling, ideal for custom solutions or evolving market needs.

Efficient Small-Batch Production: Economically produce low quantities, minimizing the financial risk associated with large-scale runs.

Companies producing custom medical implants and dental devices extensively utilize additive manufacturing for its inherent scalability and cost-effectiveness, often integrating specialized materials like Ultem (PEI).

Conclusion:

Adopting 3D printing significantly reduces upfront manufacturing costs through minimized tooling expenses, reduced material waste, accelerated prototyping, and flexible, on-demand production. Businesses seeking competitive advantages should consider integrating additive manufacturing into their production strategies. The economic efficiency and improved responsiveness to market demands position companies effectively within today's rapidly evolving manufacturing landscape.

FAQs:

What are the main ways 3D printing reduces manufacturing costs?

Can 3D printing be cost-effective for high-volume production?

How does 3D printing compare to CNC machining in terms of costs?

Which industries benefit most from cost-effective 3D printing?

Are there any limitations to cost savings in 3D printing?