Comparing the Strength of ABS Injection Molding, Silicone Molded, and 3D Printed Parts

Introduction

ABS (Acrylonitrile Butadiene Styrene) is one of the most versatile engineering plastics, widely used across various industries, including automotive, electronics, consumer goods, and medical devices. Renowned for its impact resistance, toughness, and ease of processing, ABS is popular for applications where durability and performance are essential. However, the manufacturing method for ABS parts significantly influences their final mechanical properties, particularly their strength.

This blog compares three standard manufacturing methods for ABS parts: injection molding, silicone molding, and 3D printing. Understanding the strengths and limitations of each method can help you select the proper process for your specific application.

Understanding ABS and Its Applications

ABS is a thermoplastic polymer that combines three monomers: acrylonitrile, butadiene, and styrene. These components give ABS its distinctive properties:

Acrylonitrile contributes to chemical resistance.

Butadiene provides toughness and impact resistance.

Styrene offers rigidity and a smooth finish.

ABS applications range from durable automotive components to intricate housings for consumer electronics. It's valued for strength and toughness, but each manufacturing process affects these properties in distinct ways. Let's delve into the specific methods and how they contribute to the final product's strength.

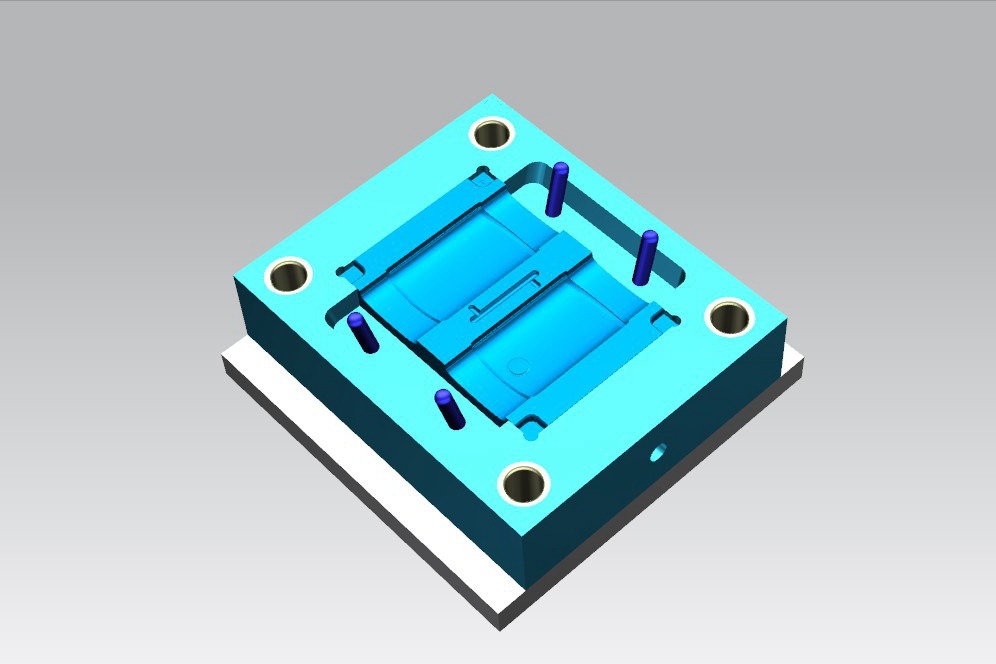

Injection Molding for ABS Parts

Injection molding is a widely used method for manufacturing ABS parts, as it enables the production of parts with high strength and durability at scale.

Overview of the Process

Injection molding involves heating ABS resin until it melts, then injecting it under high pressure into a steel mold. The molten ABS fills the cavity, and upon cooling, it assumes the shape of the mold. The high pressure used in this process ensures that the material is densely packed, resulting in a part with superior strength and minimal voids or inconsistencies.

Strength Characteristics

ABS parts produced by injection molding typically achieve tensile strengths around 40-48 MPa, the highest among the three methods discussed. This process yields a consistent molecular structure, resulting in parts with excellent impact resistance and uniform strength. Injection-molded parts exhibit isotropy, meaning their strength is consistent across all directions.

Advantages and Drawbacks

Pros: High strength and durability, excellent dimensional accuracy, smooth finish, and scalability for high-volume production.

Cons: High initial costs for mold creation, longer lead times, and less flexibility for low-volume or prototype production.

Due to these characteristics, injection molding is ideal for large production runs where part consistency, strength, and durability are priorities.

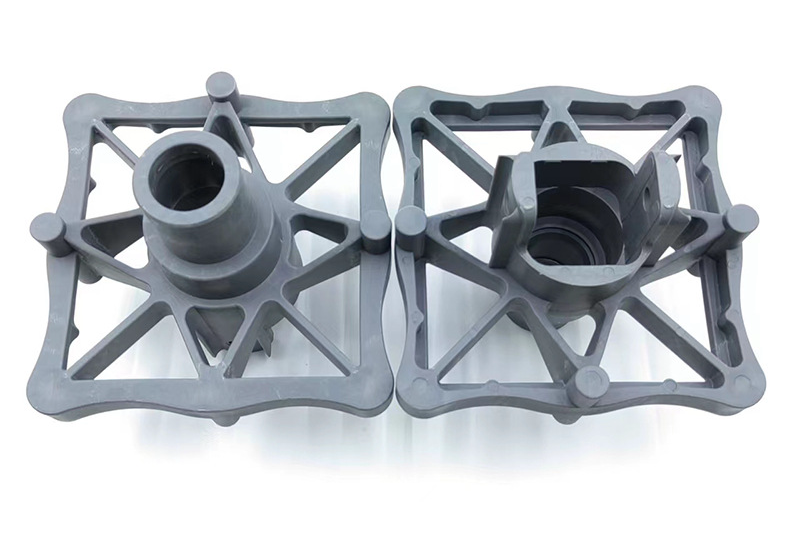

ABS Parts Made with Silicone Molds

Silicone molding, also known as soft tooling, is a versatile method often used for prototyping or producing small batches of ABS-like parts. The process typically involves creating a silicone mold from an original master model and then pouring or injecting liquid urethane or casting resin, which exhibits ABS-like properties, into the mold.

Overview of Silicone Molding

Silicone molds are relatively easy to create, making this process faster and more cost-effective for short runs than injection molding. The casting resin hardens in the mold, resulting in a part that closely mimics the appearance and flexibility of ABS.

Strength Characteristics

While silicone mold-made ABS parts can have strengths in the 25-40 MPa range, they typically fall short of the strength achieved by injection molding. This reduction in strength can be attributed to the properties of casting resins, which may not have the same molecular density and integrity as pure ABS. Additionally, some shrinkage and minor inconsistencies in material density may occur, which can affect the final part's strength.

Advantages and Drawbacks

Pros: Lower setup costs, shorter lead times, and good for low-volume production or functional prototypes.

Cons: Less strength and durability compared to injection-molded ABS, some potential for shrinkage and dimensional variation.

Silicone molding is an ideal choice for prototyping and small production runs, offering adequate strength for many applications without the high costs associated with full-scale injection molding.

3D Printed ABS Parts

3D printing, also known as additive manufacturing, is a fast and flexible method for creating ABS parts, often utilizing Fused Deposition Modeling (FDM). FDM builds parts layer by layer from ABS filament, enabling complex geometries and rapid prototyping.

Overview of 3D Printing Process (FDM)

In FDM, an ABS filament is heated and extruded through a nozzle, depositing thin layers of material that fuse to form the part. Each new layer bonds with the layer beneath it, creating a 3D object. However, the layer-by-layer approach can lead to weaker inter-layer bonds, especially along the Z-axis (vertical direction), resulting in anisotropic parts where strength varies by orientation.

Strength Characteristics 3D-printed

ABS parts typically achieve tensile strengths in the 25-35 MPa range. Due to the layered construction, these parts are more susceptible to weakness along the layer lines. The strength is highest in the XY plane (horizontal direction) but lower in the Z-axis, where inter-layer adhesion is weakest. Voids and small gaps can also appear between layers, further reducing strength.

Advantages and Drawbacks

Pros: Rapid prototyping capabilities, low-cost setup, ability to create complex or custom geometries, and flexibility for design adjustments.

Cons: Lower strength than injection molding, visible layer lines, limited durability, and variable strength depending on orientation.

3D printing is ideal for design validation and low-stress applications, but it lacks the strength required for high-load or impact-resistant parts.

Comparative Strength Analysis

To provide a more precise comparison, here’s a breakdown of the strength characteristics of each method:

Manufacturing Method | Tensile Strength Range | Isotropy | Ideal Use Cases |

|---|---|---|---|

Injection Molding | 40-48 MPa | High (Isotropic) | High-volume production, high-strength applications |

Silicone Molding | 25-40 MPa | Moderate | Small runs, functional prototypes |

3D Printing (FDM) | 25-35 MPa | Low (Anisotropic) | Prototyping, design validation, and complex geometries |

Each method has specific strengths that make it best suited for particular applications:

Injection Molding: High tensile strength, isotropic structure, and impact resistance make this method ideal for load-bearing applications and parts requiring high durability and precision.

Silicone Molding: With moderate strength, silicone molding works well for functional prototypes and short production runs where durability is essential, but costs must be minimized.

3D Printing: Although it has the lowest strength, 3D printing is suitable for prototyping and custom designs, especially where rapid production and geometric complexity are critical.

Choosing the Right Manufacturing Method for Your ABS Parts

Selecting the proper manufacturing method depends on several factors, including application requirements, production volume, budget, and design complexity.

Application Considerations:

Injection molding is generally the best choice for high-strength applications, such as structural components or automotive parts.

For prototyping and low-volume production, silicone molding offers a balance of strength and cost-effectiveness.

For complex designs or rapid iterations, 3D printing enables easy adjustments without the high upfront costs associated with molds or tooling.

Project Volume and Budget:

Injection molding is best suited for high-volume production due to its low mold costs and efficient setup time.

Silicone molding is ideal for short production runs or when creating multiple prototypes.

3D printing is most cost-effective for one-off prototypes or custom parts, eliminating the need for costly molds or setups.

Environmental and Regulatory Requirements:

Durability and reliability standards often favor injection molding, as these parts provide high strength and longevity.

Prototype testing can be done with silicone or 3D printing before committing to high-volume injection molding.